LEAPENERGY‘s BMU and BDU operate in a tightly coupled loop: the BMU continuously analyzes sensor input and instructs the BDU to perform switching actions accordingly. In return, the BDU reports the real-time status of contactors and high-voltage lines, ensuring synchronized protection and rapid fault response.

BMU integrated

in BDU

ISO 26262UN38.3UL

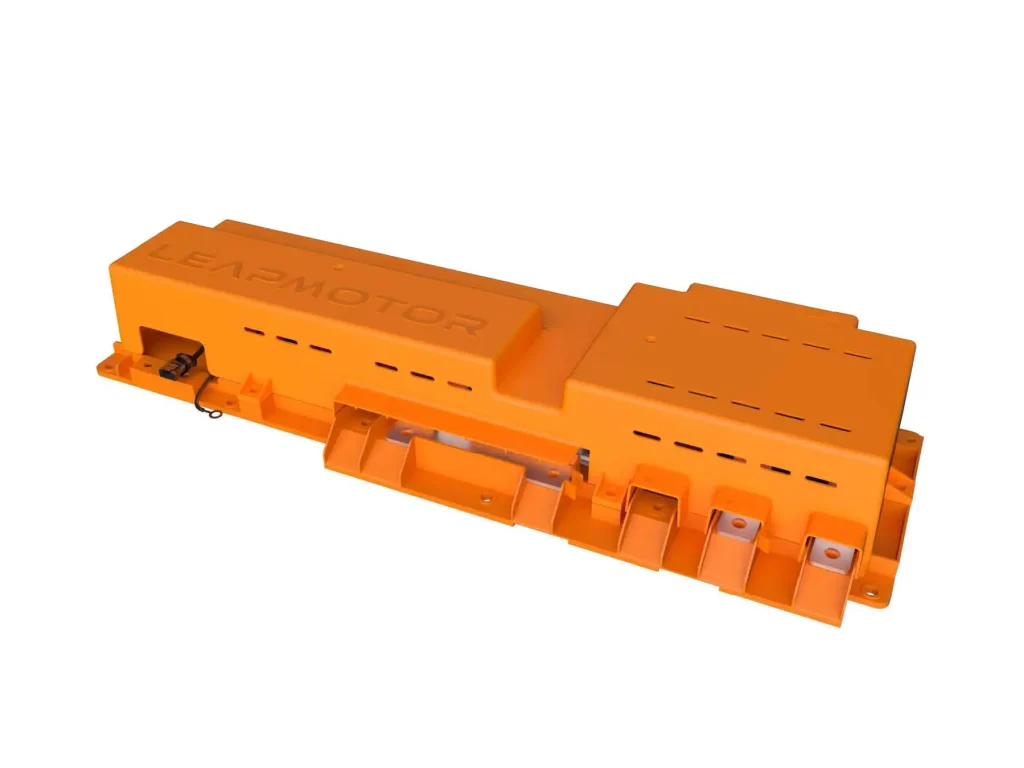

BDU: Smart Battery Protection

The Battery Disconnect Unit (BDU)ensures safe power delivery by controlling contactors for positive and negative terminals, managing pre-charge processes, and providing emergency disconnect functionality during thermal events or collisions.

BMU: Intelligent Battery Control

The Battery Management Unit provides comprehensive monitoring, control, and protection for individual cells and the entire battery pack ecosystem.

BMU + BDU – Unified Control & Safety

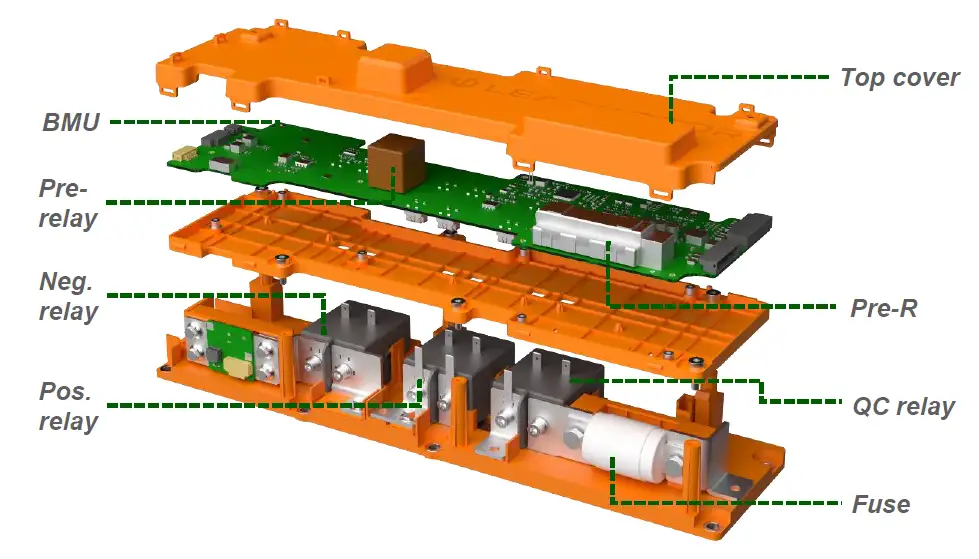

Integrating BMU and BDU into a single intelligent module reduces system complexity and enhances performance. It minimizes wire harnesses, improves electromagnetic compatibility, and enables faster reaction to faults.

High integration

BMU+ Pre-charge module+ power distribution unit

Why Integration Matters?

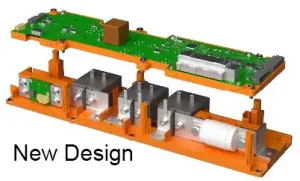

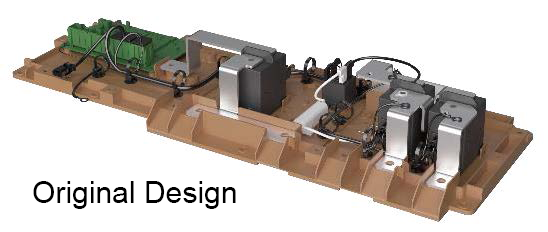

| Item | New design | Original design |

|---|---|---|

| Voltage | ≤500VDC | ≤400VDC |

| Current | ≤406A | ≤250A |

| Temperature | -40℃~85℃ | -40℃~85℃ |

| Dimensions(L/W/H) | 464*115*103.4mm | 596*169*93.7mm |

| Weight | 3.3kg | 4.05kg |

| Connection Points | 12 | 16 |

| Components | 15 | 31 |

| LV Wire-harnesses | 0 | 3 |

FAQs

What Is the Main Advantage of Integrating BMU and BDU into One Unit?

It reduces wiring complexity, improves response time, and enables compact, modular system design.

Can I Get Real-Time Data from the Integrated Unit for Remote Monitoring?

Absolutely. The BMU supports real-time data streaming for remote diagnostics and cloud-based monitoring.

How Do You Ensure Thermal and EMI Isolation Between BMU and BDU in the Same Housing?

We use multi-layer PCB shielding, thermal isolation pads, and independent ground paths to manage heat and EMI.

What Safety Certifications Do LEAPENERGY Integrated Units Have?

Our products comply with ISO 26262, IEC 62619, UL 2580, and other relevant EV/ESS safety standards.

Can LEAPENERGY Provide Technical Support and Integration Guidance?

Yes. We offer full documentation, reference designs, and engineering support for customer integration.