Failures in Requirement Definition & Supplier Alignment

Ambiguity in Requirements Traceability

Ambiguous requirements kill clarity and compromise engineering verification and validation (V&V). When the requirements traceability matrix lacks precision, thermal management specs become vague, leading to incompatible cooling designs and overheating risks. Without clear, measurable specs, teams guess at performance targets, increasing design iterations, and missing failure modes.

Vague Specs Impacting Thermal Management

Thermal issues stem from loosely defined thermal management parameters. This leads to underestimated heat dissipation needs, insufficient sensor placements, and delayed detection of thermal runaway propagation. Early-stage engineering risk assessment must demand tight, testable thermal specs to prevent system-level failures.

| Common Vague Spec Issues | Consequences |

|---|---|

| Undefined max thermal gradients | Inadequate heat spread, hotspots |

| Poor sensor calibration criteria | Sensor drift undetected post-V&V |

| Overlooked cooling startup ranges | Edge case failures in passive states |

Disconnect Between OEM Goals and Supplier Capabilities

Misalignment between OEM objectives and cell suppliers’ technical capabilities is a hidden system risk. OEMs often push aggressive density or cost targets without verifying supplier processes and quality controls, leading to battery system reliability shortfalls in mass production. Regular supplier technical capability assessments close these gaps.

The Black Box Communication Failure

Poor communication between cell manufacturers and integrators turns supplier data into a black box, obstructing root cause analysis (RCA) and system-level failure paths identification. This “information siloing” complicates cross-functional engineering reviews and delays problem resolution.

- Lack of shared failure data hampers design failure mode and effect analysis (DFMEA)

- Inconsistent documentation completeness reduces traceability during prototype validation

- Communication breakdowns increase rework cycles during design change control

Design Change Control Effects on Prototype Validation

Uncontrolled design changes introduce discrepancies between early prototypes and production units. Without rigorous change control, the prototype validation process tests outdated configurations, invalidating test results and hiding latent defects.

Key mitigation steps include:

- Enforce strict versioning and sign-offs for all design updates

- Link design changes directly to requirements in the traceability matrix

- Conduct impact analysis during each iteration to maintain quality consistency

At LEAPENERGY, we embed rigorous requirements management, continuous supplier evaluation, and transparent communication workflows. This approach ties product specs tightly to supplier capabilities, ensuring robust engineering V&V and minimizing hidden failure risks during prototype validation and beyond.

System-Level Integration Failures in Battery Systems

Integration at the system level often runs into overlooked physical interface issues that can seriously impact battery system reliability. Mechanical stress and tolerance stacking are common culprits—small variances in parts add up, leading to unexpected pressure points or misalignments that can cause premature wear or failure. Vibration resonance between the vehicle chassis and battery pack also creates fatigue risks, especially in busbars, where repeated cycles of thermal expansion and contraction worsen material fatigue.

Another frequent problem lies in BMS blind spots. After completing Engineering Verification and Validation (V&V), sensor drift and calibration errors can still creep in, compromising system accuracy over time. Edge case current inrush events during sudden power demands can degrade contactors, leading to intermittent faults or failures if not caught early.

Thermal propagation issues during passive or off states are often underestimated. Many early assessments skip these conditions, but risks such as thermal runaway spreading while the vehicle is off can lead to significant safety hazards. Addressing these hidden system risks requires robust sensor management and thorough vibration and thermal testing to optimize design robustness. For more on battery management system challenges and thermal concerns, see our detailed guide on the role of BMS in EV battery packs.

The Validation Gap: Why Testing Fails

One of the most overlooked failure mechanisms in battery system engineering is the validation gap. Relying on the golden sample fallacy—validating only hand-built prototypes that don’t fully represent mass production units—often leads to missed defects later on. Prototypes are carefully assembled and may not show the process variability or subtle failures that crop up when scaled.

Another challenge is the use of inadequate aging profiles during testing. Accelerated life testing, while valuable, can’t perfectly mimic real-world aging and usage patterns. This causes key degradation modes to be underestimated, leading to surprises in field reliability.

Additionally, software-hardware integration lags create hidden risks. Battery Management System (BMS) firmware updates sometimes introduce regressions that slip through when regression testing is incomplete or rushed. These bugs affect critical functions like sensor calibration and fault detection, which are essential to battery system reliability.

Closing the validation gap means addressing these issues head-on through rigorous engineering verification and validation (V&V) processes and including production-level consistency in test plans. For a deep dive on scaling from prototypes to mass production units and how to minimize these validation pitfalls, check out our insights on scaling EV battery pack manufacturing from prototype to mass production.

Manufacturing & Process-Induced Failure Mechanisms

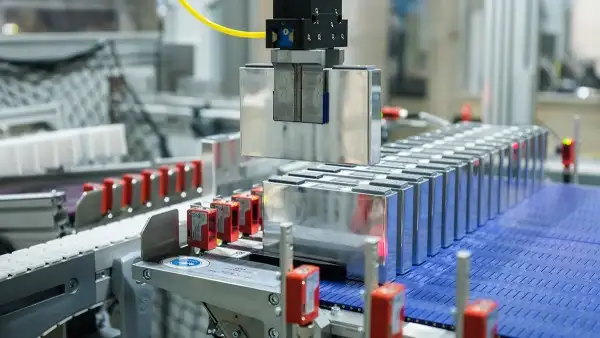

Manufacturing defects often slip through, leading to failures that only show up later in the field. One common issue is contamination and insulation breakdown—tiny debris from the manufacturing process can cause micro-failures hard to detect during assembly or early testing. These small defects can escalate to serious problems once the battery pack is in use.

Another significant risk is process drift. This happens when slight deviations in welding pressure or adhesive application occur, affecting the battery system’s overall design robustness. Even minor inconsistencies can undermine mechanical and electrical connections, resulting in premature wear or failure.

To combat this, maintaining strict control over manufacturing variables and incorporating thorough quality checks at every stage is crucial. This approach improves mass production quality consistency and ensures the long-term reliability of the battery system.

For a deep dive on designing reliable battery packs that withstand manufacturing challenges, check out best practices for designing durable automotive-grade battery packs for long-term reliability. Understanding these aspects is key to enhancing battery system reliability across the production lifecycle.

Strategic Mitigation: The LEAPENERGY Approach

At LEAPENERGY, we tackle commonly overlooked failure mechanisms with a holistic engineering verification and validation (V&V) process. Instead of just checking individual components, we simulate full system-level failure paths, ensuring early identification of risks that traditional testing often misses. This approach goes beyond prototype validation to address real-world challenges before they reach production.

Preventive design measures are key. We build in redundant safety layers and maintain rigorous documentation completeness to boost design robustness. These measures help protect against failures like thermal runaway propagation and sensor drift, reducing the chances of costly recalls or field failures.

We also treat supplier evaluation as an ongoing lifecycle partnership, not a one-time checklist. Continuous assessment of battery system supplier technical capability, including quality consistency and long-term reliability, ensures every batch meets our standards. This strategy supports smooth integration and helps avoid surprises during scale-up or mass production.

By combining thorough system-level V&V, proactive design practices, and dynamic supplier collaboration, LEAPENERGY drives battery system reliability from project start to market launch. Our approach aligns with the best industry practices on [how OEMs evaluate EV battery pack suppliers](https://leap.hiitio.com/how-oems-evaluate