Company Background and Reliability

When you sit down with an EV battery pack manufacturer, your first goal is simple: can this EV battery pack supplier actually deliver, for the long haul? Here’s what to ask before you sign anything.

Manufacturer Experience and Reference Projects

Ask directly: “What EV battery platforms have you already put on the road?”

You want proof, not theory:

- Years in EV battery pack production (not just lithium-ion in general)

- Reference projects with:

- Automotive OEMs (light-duty, commercial, off-highway)

- US fleet operators (delivery, ride-share, transit)

- EV startups that scaled from prototype to volume

- Operating data: vehicles in service, cumulative miles, failure rates, recalls

Red flag: they can’t share specific EV programs, performance metrics, or at least anonymized case studies.

Financial Stability and Long-Term Viability

A battery pack is a 8–15+ year commitment. You need to know the EV battery pack OEM will still be there.

Ask for:

- Ownership structure and investors (private equity, strategic OEMs, public company)

- Profitability and funding runway for the EV battery business

- Balance of EV vs non-EV revenue (are they committed if the market shifts?)

- Long-term service commitments documented in the contract

Red flag: vague answers on funding, no visibility into the health of their automotive battery pack factory, or no plan for long-term warranty support in the US.

Production Scale, Capacity, and Footprint

You’re not just buying a product; you’re buying a factory’s capacity and reliability.

Key questions:

- Current EV battery pack production capacity (packs/year and GWh/year)

- Utilization rate and how much capacity is realistically available to you

- Geographic footprint:

- US or North American assembly for faster EV battery pack lead times

- Redundancy across multiple plants or just one critical site

- Experience with automotive-grade volume ramp-ups

Red flag: they can’t give you a clear number on EV battery pack production, or they rely on a single overloaded plant.

R&D Strength, Patents, and Innovation Roadmap

You need a partner who can keep up with chemistry shifts, safety standards, and cost pressure.

Ask:

- In-house R&D team size and dedicated EV battery engineering capability

- Patents and IP related to:

- Pack architecture and structural design

- Thermal management and BMS algorithms

- Safety and diagnostics

- Chemistry roadmap (NMC, LFP, next-gen options) aligned to your use cases

- US-market specific innovations (cold-weather performance, fast charge focus, IRA-aligned sourcing)

Red flag: no patent portfolio, no documented roadmap, or heavy dependence on third parties for core pack design.

Track Record with OEMs, Fleets, and Startups

Different customers stress an EV battery pack manufacturer in different ways. You want all three.

Ask for:

- Automotive OEM programs: SOP dates, volumes, regions, and roles (tier-1 vs tier-2)

- Fleet deployments: delivery vans, buses, yard tractors, last-mile vehicles with real uptime data

- EV startup partnerships:

- How they supported fast iteration and custom EV battery pack design

- How many made it from prototype to series production

- US customer references you can actually call

Red flag: they only have prototype stories, no scaled programs, or no willingness to connect you with existing customers.

A serious EV battery pack manufacturer will be ready with this data. If they can’t answer these questions clearly and with evidence, they’re not ready to be your long-term EV battery pack OEM partner.

Technical Specs and Real-World Performance

When you talk to an EV battery pack manufacturer or EV battery pack OEM, push hard on real numbers, not brochure specs. Here’s what I always ask before signing anything.

Cell Chemistry (NMC vs LFP vs Others)

Ask them which chemistries they support and why they recommend each for your use:

| Chemistry | Pros | Cons | Best For |

|---|---|---|---|

| NMC | High energy density, good power | Higher cost, more sensitive to abuse | Long-range passenger EVs |

| LFP | Safer, longer cycle life, cheaper | Lower energy density, heavier | Fleets, buses, delivery vans |

| Others (NCA, LMO, solid-state dev) | Niche advantages | Less mature or costlier | Special performance use cases |

Key questions:

- What chemistries do you offer for custom EV battery packs?

- What’s the trade-off in cost per kWh, weight, and safety for each option?

- What chemistries are actually in mass production today?

Energy Density, Voltage, Capacity, Cycle Life

Don’t accept “lab” numbers. Ask for tested data in real U.S. conditions.

- What pack-level energy density (Wh/kg, Wh/L) do you guarantee?

- What nominal voltage and voltage window fit my platform (400V vs 800V)?

- Tested cycle life to 70–80% capacity under:

- Typical U.S. drive cycles

- Fast charging

- High/low ambient temperatures

If you’re targeting 400V or 800V architectures, ask how their packs compare to what’s outlined in a modern 400V vs 800V EV platform breakdown like this 400V vs 800V EV battery pack guide.

Charging Rates, Fast-Charge, and Degradation

Fast charging is where many packs die early.

- Max continuous and peak charge C-rate (AC and DC)

- 10–80% fast-charge time at standard U.S. DC fast chargers

- Capacity loss:

- After X fast-charge cycles

- After Y years in hot/cold climates

- Recommended charging profiles to avoid what typically kills batteries faster (similar to the patterns explained in this piece on behaviors that kill EV batteries faster)

Thermal Management & Extreme Climates

U.S. fleets see everything from Arizona heat to Minnesota winters.

Ask:

- Cooling type: air, liquid, refrigerant-based, or hybrid?

- Designed operating temp range and derating behavior

- Performance guarantees at:

- -20°F winters

- 100°F+ summers

- How they test for thermal runaway propagation and hot-spot prevention

BMS Functions, Safety Logic, Data Access

Your battery management system (BMS) is the brain. Don’t treat it as a black box.

Confirm:

- Core functions: cell balancing, SOH/SOC estimation, fault detection

- Safety logic: over/under voltage, current, temp, short-circuit protection

- Data access:

- What real-time data can your team read (CAN, Ethernet, OTA)?

- Who owns the data and logs?

- Can they support fleet telematics and remote diagnostics?

Hardware & Software Compatibility

Integration pain can kill your launch timeline.

- Supported communication protocols (CAN bus, CAN FD, LIN, etc.)

- Compatibility with your inverter, charger, and VCU:

- Message IDs

- DBC files

- Diagnostics (UDS, OBD-II if needed)

- Software update support:

- OTA ready?

- Who manages firmware version control?

Make them show proof: existing integrations with automotive OEMs, EV startups, or fleet platforms similar to yours in the U.S. market.

Customization and Design Capabilities

When I talk to an EV battery pack manufacturer or EV battery pack supplier, customization is one of the first filters I use. If they can’t design around your vehicle, your pack will always be a compromise.

Custom EV Battery Pack Design Options

Ask how far they can go with a custom EV battery pack:

- Pack size & shape: Can they design around your actual vehicle envelope, not force you into a standard box?

- Modules & layout: Can they adjust module count, cell format, and busbar layout to hit your energy and power targets?

- Cooling concept: Do they support air, liquid, or refrigerant cooling, and can they model thermal performance for your duty cycle?

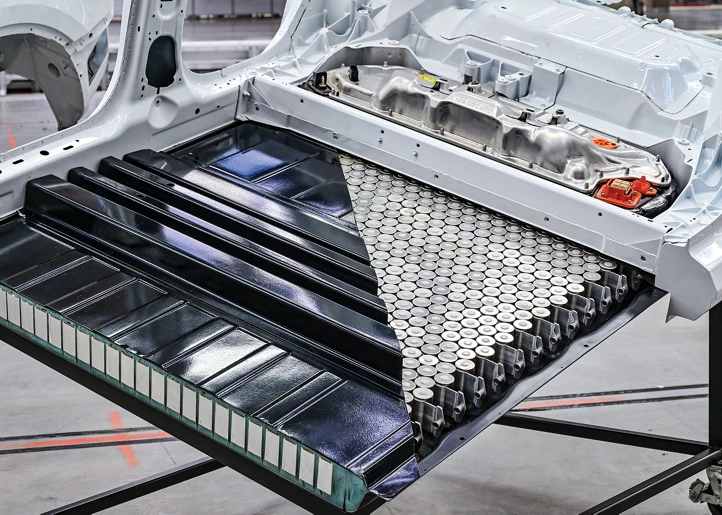

For context on how different pack architectures affect design freedom, I often point people to overviews comparing modular vs integrated EV battery packs like this breakdown of modular vs integrated pack systems.

Mechanical, Electrical, and Software Integration

A serious EV battery pack OEM should plug cleanly into your platform:

- Mechanical: Mounting points, crash structures, IP rating, enclosure stiffness, serviceability.

- Electrical: Voltage window, current limits, HV/LV interfaces, contactors, fuses, DC fast charge compatibility.

- Software/BMS: CAN signals, diagnostics, SOC/SOH reporting, torque/speed limits, and integration with your VCU and telematics.

Ask them to show a full integration spec they’ve used with other automotive OEM battery sourcing projects.

Prototyping and Validation

You want a clear path from concept to SOP:

- Prototype phases: How many sample builds (A/B/C samples)? What’s included in each?

- Lead times: How long from design freeze to first prototype pack? To validation packs?

- Validation scope: Do they support vibration, thermal, abuse, EMC, and vehicle-level testing?

Have them map out a timeline and responsibilities so your engineering and purchasing teams can lock in milestones.

Design for Manufacturability and Scale

Custom is useless if it can’t scale:

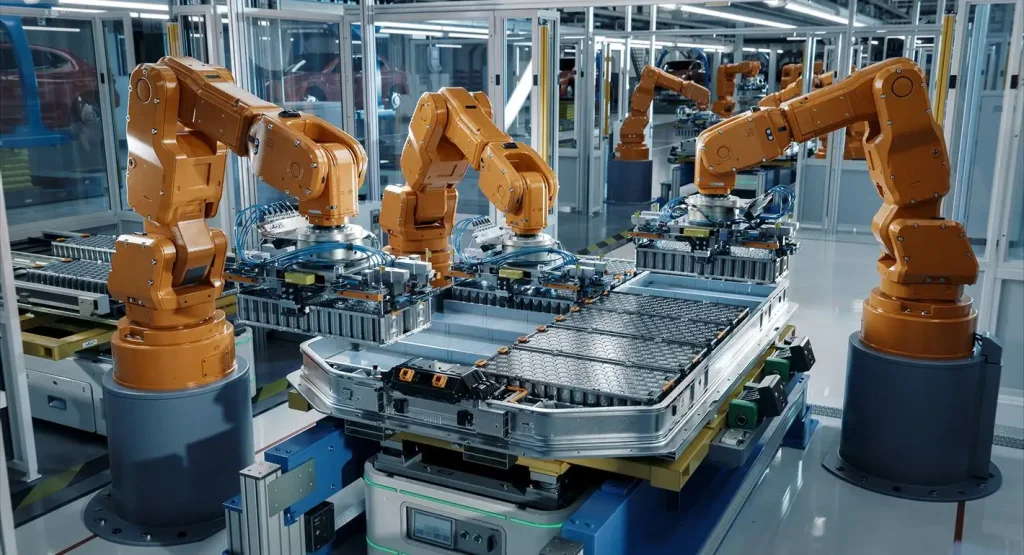

- Do they design for robotic assembly, standard components, and minimal manual operations?

- Can the same design ramp from pilot to mass production without major redesign?

- How do they control EV battery pack cost per kWh as volume increases?

Push for examples of projects where they scaled from low-volume pilots to full production.

Support for Different Applications

If you’re in the U.S. market, duty cycle matters as much as chemistry. Ask what they can support:

- Passenger EV: High energy density, quiet operation, refined thermal control.

- Commercial & fleet: High uptime, fast charge, robust enclosures, strong warranty.

- Stationary storage: Different cycle profile, grid integration, safety codes.

- Off-highway: Heavy shock, dust, mud, extreme temps.

Your EV battery procurement checklist should include: “Have they done packs for applications similar to mine, in similar U.S. climates and regulations?”

Manufacturing Quality and Testing: Questions to Ask an EV Battery Pack Manufacturer

When you’re choosing an EV battery pack supplier in the U.S. market, manufacturing quality and testing are non‑negotiable. Before you sign anything, I’d drill into these points:

Key Certifications and Standards

Ask your EV battery pack manufacturer directly:

- Which certifications do you hold?

- IATF 16949 (automotive quality)

- ISO 9001 (quality management)

- ISO 26262 (functional safety for automotive)

- Are these certifications valid for the specific factory that will build your packs?

- How often are you audited, and by whom (third‑party vs internal)?

If you’re targeting UL and automotive safety, make sure their process supports UL 2580 and ISO 26262 EV battery certifications like those outlined in this guide on EV battery pack safety and compliance.

Process Control and Traceability

For any serious EV battery pack OEM, you should confirm:

- Do you have full traceability down to cell lot, module, and pack serial number?

- What in‑line inspection systems do you use?

- Automated optical inspection (AOI)

- X‑ray checks for welds and busbars

- End‑of‑line electrical tests

- How is process data logged and stored, and can we access it for our packs?

This is critical if you plan to scale EV battery pack production and need a clean audit trail for quality or recalls.

End‑of‑Line and Abuse Testing

You want proof they don’t just assemble packs—they stress‑test them:

- What end‑of‑line tests does every pack go through?

- Insulation resistance

- Hi‑pot test

- Charge/discharge functionality

- BMS communication checks

- Do you perform burn‑in testing (running packs under load before shipment)?

- What safety and abuse tests are part of your standard process?

- Overcharge / over‑discharge

- Short‑circuit

- Thermal shock / vibration

- Nail penetration or crush (if applicable to your spec)

Validate that these test protocols align with EV battery safety standards like UN 38.3 and UL 2580, not just internal company rules.

Defect Rates and Corrective Actions

Don’t accept vague answers—ask for real numbers:

- What are your typical defect rates (PPM) at:

- Incoming components (cells, BMS)

- In‑process assembly

- End‑of‑line testing

- Can you share field failure data for similar EV battery pack designs?

- How do you run root cause analysis (RCA) and corrective actions?

- 8D reports?

- How fast can you implement process changes?

You want a battery pack supplier that is transparent about problems and has a mature quality system, not one that hides issues.

Audits, Factory Visits, and Transparency

Before locking into an EV battery contract, I’d insist on:

- On‑site audit or virtual factory tour:

- Cell storage conditions

- ESD (electrostatic discharge) controls

- Cleanliness of assembly lines

- Access to:

- Sample control plans

- PFMEAs (Process Failure Mode and Effects Analysis)

- Calibration logs for key equipment

- Agreement that you can perform periodic audits during the contract term.

If they’re not comfortable showing you their EV battery manufacturing process, that’s a red flag. A strong EV battery pack manufacturer will be proud to walk you through their quality controls, testing protocols, and safety features, similar to how we outline key safety features in EV battery packs on our own [battery safety overview page](

Safety and Regulatory Compliance: What to Ask an EV Battery Pack Manufacturer

When I vet an EV battery pack supplier, safety and compliance are non‑negotiable. Here’s exactly what I ask before signing anything.

Built‑In Safety Features and Redundancies

Ask the EV battery pack manufacturer to walk you through every built‑in protection:

- Overcharge / over‑discharge protection: How does the BMS detect and react? What are the cut‑off thresholds?

- Short‑circuit and over‑current protection: What hardware fuses, relays, or battery disconnect units are used? Are they redundant?

- Thermal runaway prevention:

- Cell‑level protection (vents, separators)

- Pack‑level design (fire barriers, venting paths, isolation zones)

- Isolation and leak detection: How is insulation resistance monitored in real time?

You want clear descriptions, not vague “we’re safe” claims. For a deeper framework on pack‑level protection, I often compare their approach to modern battery disconnect units that enhance EV safety.

EV Battery Safety Standards (UN 38.3, ECE R100, IEC, UL)

Make the EV battery pack OEM prove compliance with relevant standards for your use case:

- UN 38.3 for lithium‑ion transport safety (mandatory for shipping)

- ECE R100 for road EVs in many global markets

- IEC standards (e.g., IEC 62660, IEC 62133) depending on your segment

- UL standards for North America (e.g., UL 2580 for EV battery packs)

Key questions:

- Which specific standards and versions are they certified to?

- Are certificates for the full pack, or only for cells/modules?

- Will they support re‑certification if you require custom EV battery pack design changes?

Regional Regulatory Compliance

If you’re selling EVs or fleet battery packs in the United States, Europe, and beyond, pin the supplier down on:

- Which regions and regulations their packs are already approved for

(U.S. DOT, FMVSS links, EU type approval, etc.) - Whether they have experience with state‑level rules (e.g., California) that affect EV battery compliance

- How they track regulatory changes that may impact future model years

You want an EV battery pack supplier that can scale regulatory compliance with your market roadmap, not slow it down.

Documentation, Test Reports, and Certification Packages

Before you lock in an EV battery procurement contract, confirm what documentation you’ll actually get:

- Full test reports (abuse tests, thermal tests, vibration, shock, IP rating, etc.)

- Certificates for UN 38.3, ECE R100, IEC, UL and any local approvals

- Traceable serials and test results for each pack or batch

- A complete compliance and validation package you can share with regulators, insurers, and fleet customers

If documentation is “available on request” but never shows up, that’s a red flag.

Functional Safety and Hazard Analysis

EV battery safety isn’t just hardware; it’s also functional safety and software logic:

- Do they follow ISO 26262 or similar functional safety processes for the BMS?

- Can they perform or support Hazard Analysis and Risk Assessment (HARA) specific to your application (passenger EV, commercial trucks, off‑highway, storage)?

- How are faults detected, logged, and mitigated (derating, limp mode, contactor open, alerts to the vehicle ECU)?

- How is cybersecurity handled for over‑the‑air updates and remote access to BMS data?

If their answers sound aligned with a structured EV battery pack guide like this EV battery pack guide explained, you’re likely dealing with a mature EV battery pack manufacturer. If not, keep looking.

Supply Chain and Sourcing Ethics With an EV Battery Pack Manufacturer

When I talk to an EV battery pack supplier, I drill into supply chain ethics up front. In the U.S. market, customers, fleets, and investors are watching this closely, so I want everything clear in the contract.

Cell Suppliers and Qualification

Ask the EV battery pack manufacturer:

- Who are your cell and critical component suppliers? (names, regions, chemistries)

- How do you qualify them? (audit process, test criteria, minimum quality standards)

- Do you rely on a single cell source or multiple OEMs?

I prefer suppliers that already work with major EV battery pack OEMs and are listed among established global players, similar to those in the top global EV battery pack suppliers overview.

Raw Material Transparency and Traceability

You want full visibility from mine to module:

- Can you provide traceability down to cell lot, cathode/anode material, and key metals?

- Do you maintain material origin documentation (country of origin, smelter/refiner info)?

- Do you support customer audits or third‑party traceability checks?

If they can’t trace materials, you’re taking regulatory and brand risk.

Conflict‑Free Minerals and OECD Compliance

I always ask for written alignment with OECD Due Diligence Guidelines and U.S. expectations (Dodd‑Frank style conflict minerals rules):

- Are cobalt, lithium, nickel, and manganese conflict‑free?

- Do you have smelter/refiner lists and third‑party audits?

- Can you commit to no sourcing from embargoed or high‑risk regions without mitigation?

This matters for EV fleets and automotive OEM battery sourcing, especially when you’re selling into corporate or government contracts.

Multi‑Sourcing and Risk Management

A serious EV battery pack supplier should have:

- Multi‑sourcing for cells, BMS components, and key electronics

- Clear risk management plans for political disruptions, export controls, or raw material shortages

- Buffer stock and alternative logistics routes to protect battery pack lead times

Ask how they handled real disruptions (COVID, shipping delays, price spikes) and what changed in their strategy.

ESG, Child Labor, and Responsible Practices

I put this in the contract, not just in a slide deck:

- Formal policies banning child labor, forced labor, and unsafe working conditions

- ESG reporting or sustainability KPIs tied to suppliers

- Alignment with your own corporate code of conduct and U.S. buyer expectations

For an EV battery procurement checklist, I treat ESG and sourcing ethics as a go/no‑go item, not a “nice to have.” If a supplier can’t document this, I move on to another EV battery pack manufacturer.

Sustainability and End-of-Life Strategy: What to Ask an EV Battery Pack Manufacturer

When I evaluate an EV battery pack supplier, I treat sustainability and end‑of‑life as hard requirements, not “nice to have.” Here’s exactly what I ask before signing anything.

Recycled and Low‑Carbon Materials

- Do you use recycled or low‑carbon materials in the EV battery pack (aluminum housings, copper, cathode materials, plastics)?

- Can you quantify the percentage of recycled content and provide documentation?

- Are you working with any low‑carbon cell suppliers or low‑carbon aluminum/steel sources?

Carbon Footprint and LCA Support

- Can you provide carbon footprint data per kWh for your EV battery pack (cradle‑to‑gate)?

- Do you offer life‑cycle assessment (LCA) support so I can meet U.S. and EU reporting requirements?

- How often do you update your footprint models when your EV battery pack production or sourcing changes?

Design for Recycling and Material Recovery

- How is the pack designed for recyclability (fast disassembly, standard fasteners, minimal glue, labeled materials)?

- What recovery rates can recyclers typically achieve for lithium, nickel, cobalt, copper, and aluminum from your packs?

- Do you design your custom EV battery pack modules so cells can be safely removed and processed?

Second‑Life Use for EV Battery Packs

- Do you support second‑life applications (stationary storage, commercial backup, microgrids) for used EV battery packs?

- Who owns the state‑of‑health (SOH) data and how is it shared to qualify packs for second‑life use?

Warranty and After‑Sales Support: What to Ask an EV Battery Pack Manufacturer

Before you sign with any EV battery pack supplier, lock down the warranty and after‑sales support in writing. This is where a “cheap” pack can get very expensive later.

Standard EV Battery Warranty Duration

Ask the manufacturer to clearly define:

- Warranty period:

- Years: e.g., 8–10 years for passenger EVs, 5–8 years for fleets/commercial.

- Usage: miles or operating hours (e.g., 100,000–150,000 miles, or 3,000–5,000 hours).

- Whether the warranty is whichever comes first (time vs miles/hours).

- If different use cases (taxi, delivery, off‑highway) get different coverage.

Capacity Retention and Claim Triggers

You need hard numbers, not vague promises:

- Capacity retention guarantee: e.g., 70–80% of original capacity at a set time/mileage.

- How capacity is measured and verified (test method, temperature, SOC window).

- Clear triggers for a warranty claim:

- Capacity below stated threshold

- Repeated BMS faults or safety shutdowns

- Abnormal degradation vs their own fleet data

What’s Covered vs Excluded

Push for a simple, honest list of inclusions and exclusions:

Covered (should be):

- Manufacturing defects (cells, BMS, welds, sealing)

- Premature degradation under normal use

- Failures tied to approved charging hardware and software

Typically excluded:

- Abuse (impact, flooding, tampering, bypassing BMS)

- Unapproved software changes, BMS reflashing, or tuning

- Operation outside specified temperature or voltage limits

- Non‑OEM chargers or DC fast charging that exceeds their spec

Get these in the contract so there’s no argument later.

Repair, Replacement, and Field Service

Don’t just ask if they “support” you – ask how fast and how:

- Response times:

- Initial remote diagnosis SLA (e.g., 24–48 hours)

- On‑site support window for critical fleet downtime

- Repair vs replacement rules:

- Module‑level vs full pack replacement

- Who pays shipping, labor, travel, and lift/handling costs

- Field service footprint in the US:

- Local service partners, training centers, and spare parts stock

- Ability to support multi‑state or nationwide fleets

Monitoring, Diagnostics, and BMS Data Access

For EV fleets and startups, data is everything:

- Remote monitoring options via the battery management system (BMS):

- Real‑time SOC, SOH, temperatures, alarms, charge cycles

- API or cloud access for your fleet platform

- Ownership and use of BMS and telematics data

- Whether you can access detailed diagnostics without voiding the warranty

If you’re pushing into high‑voltage architectures, ask how their BMS and diagnostics integrate with advanced packs like modern 800V EV batteries and what level of data visibility you get.

Training, Documentation, and Tech Support

Finally, make sure your team isn’t left guessing:

- Technical training for engineers, service techs, and dealers:

- Safety handling, diagnostics, pack replacement, and commissioning

- Documentation package:

- Service manuals, wiring diagrams, BMS interface docs, fault codes

- Support channels in the US:

- Dedicated account engineer

- 24/7 emergency line or at least extended‑hours support for fleets

Put all of this into your EV battery contract terms so warranty and after‑sales support are enforceable, not just “verbal assurances.”

Production Capacity and Delivery Performance

When I’m choosing an EV battery pack supplier, I drill hard into production capacity and delivery performance. If they can’t scale or ship on time, nothing else matters.

1. Current EV Battery Pack Production Capacity

Ask the EV battery pack manufacturer to quantify their real capacity today, not just future plans:

- What is your current EV battery pack production capacity (packs/month and GWh/year)?

- What’s your typical utilization rate? (Are they running at 60% or already overloaded at 95%?)

- How much of that capacity is already committed to other automotive OEMs or EV fleets?

You want a battery pack OEM that can show hard data from the factory floor, not just a sales slide.

2. Scalability for Your Volume Ramp-Up

Your ramp will likely be lumpy. Make sure the EV battery pack supplier can grow with you:

- What’s your expansion plan for the next 3–5 years?

- What capex is already funded and scheduled (new lines, automation, added shifts)?

- What’s the maximum volume you can support if our demand grows faster than planned?

For larger commercial and industrial projects, I also look at how they’ve scaled similar programs before. A manufacturer that’s already supporting multi-site commercial and industrial energy storage deployments usually has stronger planning and capacity controls.

3. Lead Time and Delivery Rhythm

You need clarity on how fast packs move from purchase order to your dock:

- Standard lead time from PO to first delivery (new program vs. repeat orders)

- Lead time to reach steady-state supply for ongoing EV battery pack production

- Forecast and order policies: frozen windows, rescheduling rules, and safety stock options

I ask for a clear lead-time table by volume (prototype, pilot, SOP, and mass production) so I can build a realistic EV battery procurement checklist and launch timeline.

4. On-Time Delivery and Logistics Capabilities

Past delivery performance is a strong predictor of future headaches:

- Historic on-time delivery performance (OTD % by quarter over the last 12–24 months)

- Typical shipping modes (air vs. sea vs. ground) and who owns logistics (Incoterms)

- Experience shipping hazmat lithium-ion packs into the U.S. and other target markets

If they can’t provide solid on-time delivery metrics, I assume their planning and logistics process is weak.

5. Contingency Plans and Supply Chain Risk

Given raw material volatility and lithium-ion battery sourcing risks, I always push on backup plans:

- What happens if a key cell supplier or raw material source is disrupted?

- Do you have multi-sourcing for critical components and qualified alternates?

- Do you carry safety stock for cells, BMS, and key pack components?

- What’s your documented business continuity plan for natural disasters or geopolitical shocks?

A reliable EV battery pack manufacturer should show you written contingencies, not just verbal promises. When I evaluate partners, I treat this as core risk management, not a nice-to-have.

Pricing, Cost Structure, and Commercial Terms

When you’re picking an EV battery pack supplier, you have to get very specific on pricing and commercial terms before you sign anything.

Battery pack pricing model and cost per kWh

Ask the EV battery pack manufacturer to lay out their pricing model in detail:

- Pack price and cost per kWh: Get a line‑item breakdown (cells, modules, pack enclosure, BMS, cooling, wiring, assembly).

- What changes with spec: How chemistry, energy density, voltage, or custom design impact battery pack cost per kWh.

- Different use cases: Confirm pricing differences for passenger EV, commercial fleet, and storage packs.

Tie this into your own business model so you know exactly where your margin lands at different volume levels.

One‑time costs and NRE

Clarify all one‑time costs up front:

- Tooling (pack housing, module fixtures, harnesses)

- Engineering and custom EV battery pack design

- Validation and testing

- Certification support (e.g., UN 38.3, UL, automotive)

Lock these into the contract so there are no “surprise” invoices mid‑project.

MOQ and volume price breaks

For any EV battery pack OEM or automotive battery pack factory, you need:

- Minimum order quantities (MOQ) by configuration

- Price breaks by volume (yearly volume, lifetime volume, or per PO)

- Whether they support ramp‑up pricing for startups and fleets scaling over 12–36 months

This is critical for EV startups and new fleet programs that won’t hit peak volume on day one.

Payment terms, Incoterms, and shipping

Spell out commercial terms in black and white:

- Payment terms: 30/60/90 days, deposits, milestones for engineering and tooling

- Incoterms: EXW, FOB, CIF, DAP, etc., and who owns risk at each point

- Shipping responsibilities: Who handles freight, insurance, and dangerous goods paperwork for lithium‑ion packs

If you need help structuring a sourcing program for the US market, reach out through our contact page and we’ll walk you through typical EV battery procurement setups.

Price adjustment mechanisms

EV battery pack production is tightly linked to raw material prices and currency:

- Ask how they index prices to lithium, nickel, cobalt, copper, aluminum.

- Confirm how often pricing is reviewed (quarterly, annually).

- Define caps, floors, or formulas for material and FX adjustments so you’re not exposed to unlimited upside.

Total cost of ownership (TCO)

Don’t just chase the lowest quote. For real EV battery pack sourcing, ask for a total cost of ownership view:

- Efficiency and usable energy (kWh you can actually use)

- Cycle life and degradation (how long until capacity drops to your warranty limit)

- Failure rates, warranty risk, and field service costs

- Charging behavior and impact on your energy and infrastructure costs

Often, a slightly higher battery pack cost per kWh with better life and lower failure rates is cheaper over the vehicle’s life. Make them show that math, not just the headline pack price.

Contractual Protections and Risk Management With an EV Battery Pack Manufacturer

When I talk to any EV battery pack supplier or EV battery pack OEM, I lock down the contract details as hard as the technical specs. Here’s what I make sure is crystal clear before I sign anything.

IP Ownership, Joint Development, and Licensing

For custom EV battery pack design, I spell out exactly who owns what:

- Who owns IP for pack design, BMS algorithms, harness layouts, thermal management, and software

- Joint development terms if we co-design: who can reuse the design, where, and for which customers

- Licensing rights if I want to use the battery management system (BMS) or software with another EV battery pack manufacturer later

- Use of my brand and data so the supplier can’t reuse my design or data for competitors

In the U.S. market, clean IP language is non‑negotiable. It protects my future product roadmap and valuation.

NDA, Confidentiality, and BMS Data Ownership

For any EV battery pack sourcing deal, I always ask:

- Is there a strong NDA covering drawings, pricing, and test data?

- Who owns the BMS and telematics data from my vehicles and fleets?

- Can I export data into my own cloud, analytics tools, or fleet platform?

- Are there limits on data sharing with their other customers or partners?

I want control of my field data so I can improve range, uptime, and TCO for U.S. customers.

Liability, Indemnification, and Recalls

With any automotive battery pack factory, I push hard on liability:

- Clear liability and indemnification for defects, fire risk, or safety issues

- How they handle product recalls (voluntary vs. mandated) and who pays for what

- Caps on liability (if any), and how they handle consequential damages

- Insurance levels: product liability, recall insurance, and coverage in the U.S.

If an EV battery pack fails in the field, I don’t want finger‑pointing—I want a defined, funded process.

Force Majeure, Penalties, and Performance Guarantees

I want the contract to reflect real EV battery production risks:

- Force majeure scope (pandemics, raw material shortages, trade restrictions, tariffs)

- Performance guarantees for:

- Pack quality

- On‑time delivery

- Capacity and safety performance

- Penalties or credits for missed delivery, repeated failures, or under‑performance

- Clear service level agreements (SLAs) for response times on critical issues

This matters when I’m scaling production in North America and can’t afford line stoppages.