The Safety Imperative – Protecting Drivers in an Electrified Future

Electric vehicles (EVs) are reshaping mobility, but with new powertrain technologies come evolving safety risks—from thermal runaway in high-voltage batteries to software faults impacting critical systems. How can OEMs guarantee driver safety in this complex landscape?

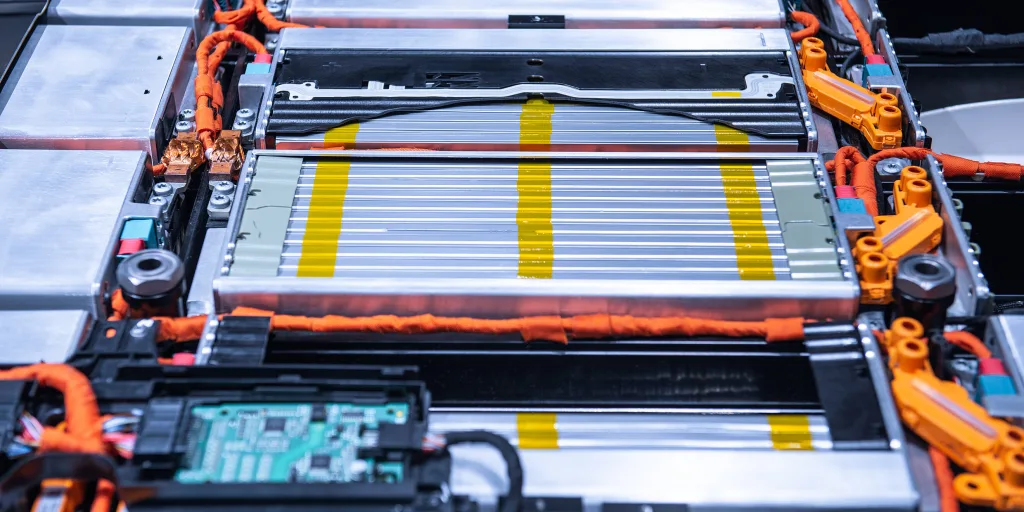

UL 2580 certification plays a crucial role by verifying the integrity and safe performance of lithium-ion battery packs. It focuses on physical safety aspects like thermal management, fast charging protocols, and cell containment. This rigorous testing ensures battery reliability under real-world stresses, reducing hazards related to overheating or mechanical failure.

Meanwhile, ISO 26262 sets the standard for functional safety in automotive electronics. It provides a structured approach to identifying risks through hazard analysis and risk assessment (HARA), defining Automotive Safety Integrity Levels (ASIL), and managing safety throughout the product lifecycle. ISO 26262 ensures that software and hardware work fault-tolerantly to prevent unsafe vehicle behavior.

Together, these certifications offer a synergistic safety framework:

| Certification | Focus Area | Key Benefits |

|---|---|---|

| UL 2580 | Battery pack safety and performance | Assures physical and thermal integrity |

| ISO 26262 | Functional safety of electronics/software | Prevents system-level failures, reduces recalls |

For OEMs, pursuing both UL 2580 and ISO 26262 is no longer optional—it’s essential for protecting drivers and maintaining market trust in an electrified future. What if a dual certification strategy could be your strongest defense—and your competitive advantage?

Regulatory and Market Access Drivers – Meeting Global Demands

Global OEMs face a complex regulatory landscape when designing EV battery systems. North America, Europe, and Asia each have unique safety and performance standards that must be met to ensure legal market access. UL 2580 certification for lithium-ion packs is often mandatory in the U.S. and Canada, focusing on battery pack safety, including thermal management and fast charging protocols. Meanwhile, ISO 26262 addresses automotive functional safety, requiring manufacturers to meet strict ASIL levels tailored to EV powertrain risks.

OEM supplier qualification processes now routinely include verification of UL 2580 and ISO 26262 certifications. This dual compliance demonstrates not only that battery systems meet regulatory requirements but also that they have undergone hazard analysis and risk assessment (HARA), ensuring functional safety throughout the product lifecycle. Achieving these certifications is a key step in preventing costly automotive recalls and safeguarding brand reputation.

For OEMs aiming to expand their EV market share, compliance with both standards translates into broader access across key regions and faster time to market. LEAPENERGY’s certified EV battery solutions offer a practical example of how meeting these global standards can accelerate supplier approval and support growing demand for energy-efficient EV battery design. Their approach leverages the latest high-voltage EV architecture and Tier 1 supplier qualification processes, positioning OEMs for success.

To explore how these certifications fit into your supply strategy, check out our detailed global EV battery pack market outlook for 2025–2030.

Business and Innovation Advantages – Beyond Compliance

Getting UL 2580 and ISO 26262 certifications isn’t just about meeting rules — it’s a smart business move. These certifications help OEMs save money by reducing risks like recalls, warranty claims, and liability. When your EV battery meets strict safety and functional standards, you’re cutting down costly surprises before they happen.

On top of safety, certified battery packs boost energy efficiency and performance. Optimized thermal management, better battery management system (BMS) certification, and streamlined high-voltage EV architecture mean longer range and faster charging — huge wins for customer satisfaction.

Having dual certification also gives OEMs a clear advantage in the supply chain. Tier 1 suppliers and partners prioritize working with certified vendors, improving supplier qualification processes and speeding up time to market.

Finally, these certifications future-proof your EV products against evolving global standards. Staying ahead of regulatory curves not only protects your brand but sets you up to lead innovation in energy-efficient EV battery design.

Explore how certified lithium-ion battery packs fit into modern EV strategies, including energy storage and hybrid solar solutions, through LEAPENERGY’s comprehensive battery pack guide.

Implementation Roadmap – Achieving Certification for OEM Success

Meeting UL 2580 certification and navigating ISO 26262 requirements can seem complex, but a clear roadmap helps OEMs succeed efficiently. Here’s how to integrate these certifications into your EV battery strategy:

Step-by-Step Guide to UL 2580 Compliance

- Understand the Standard: UL 2580 focuses on lithium-ion battery pack safety, including thermal management, electrical integrity, and fast charging safety protocols.

- Perform Hazard Analysis: Conduct thorough hazard analysis and risk assessment (HARA) to identify potential failure modes.

- Design and Test: Apply high-voltage EV architecture best practices and rigorously test your battery packs under real-world conditions.

- Documentation and Audits: Prepare comprehensive reports and submit your product for third-party UL testing and certification.

Navigating ISO 26262 Certification

- Define ASIL Levels: Classify your EV powertrain components by Automotive Safety Integrity Levels (ASIL) based on risk.

- Functional Safety Lifecycle: Implement the ISO 26262 functional safety lifecycle, including development, validation, and verification of safety functions.

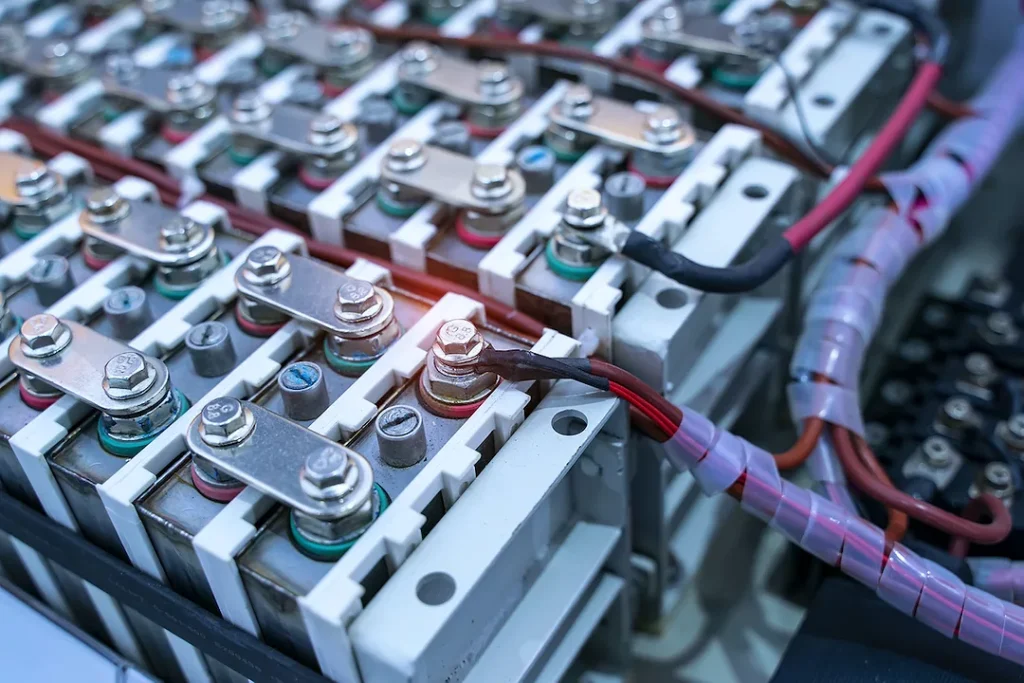

- BMS Certification: Ensure your battery management system (BMS) meets automotive functional safety standards.

- Continuous Monitoring: Adopt ongoing safety management practices to meet evolving risks in EV battery systems.

Integrating Certifications into OEM Battery Strategies

Successfully combining UL 2580 and ISO 26262 means embedding safety into every step of your design and supply chain processes. By aligning battery pack designs with these standards, OEMs boost supplier qualification success and reduce wiring complexity in advanced 800V EV platforms, enhancing both safety and energy efficiency.

Partnering with Experts: LEAPENERGY’s Support

LEAPENERGY offers targeted support for OEMs aiming for dual certification success. Leveraging expertise in modular and integrated battery designs, LEAPENERGY helps streamline certification while optimizing battery performance and fast charging capabilities. Explore how LEAPENERGY’s certified solutions fit within advanced EV battery strategies, including high-voltage systems, at their pages on modular vs. integrated EV battery packs and 400V vs. 800V EV battery pack platforms.

By following this roadmap, OEMs can confidently meet global safety requirements, unlock market access, and build robust, future-ready EV powertrains.