Unmatched Cost Effectiveness for High Volume Fleets

When managing a large commercial EV fleet, cost is a critical factor. Lithium iron phosphate (LFP) batteries deliver exceptional value by significantly lowering upfront and operational expenses compared to other chemistries like nickel manganese cobalt (NMC). Here’s why LFP stands out:

- Lower material costs: LFP batteries use abundant, cobalt-free materials, reducing dependence on expensive metals and volatile supply chains.

- Reduced battery pack price: Fleet operators see up to 20-30% cost savings per kWh, making large-scale deployment more budget-friendly.

- Longer useful life: Thanks to their extended cycle life, LFP packs need fewer replacements, cutting maintenance and downtime costs.

- Stable pricing trends: The ethical and abundant raw materials lead to less price fluctuation, helping fleets plan their budgets confidently.

Commercial operators like delivery and transit companies benefit most by optimizing total cost of ownership without compromising performance. The combination of affordability and durability makes LFP batteries the top choice when scaling EV fleets nationwide.

Image Source: https://www.google.com/Fwhich_is_better_lfp_or_nmc_batteries

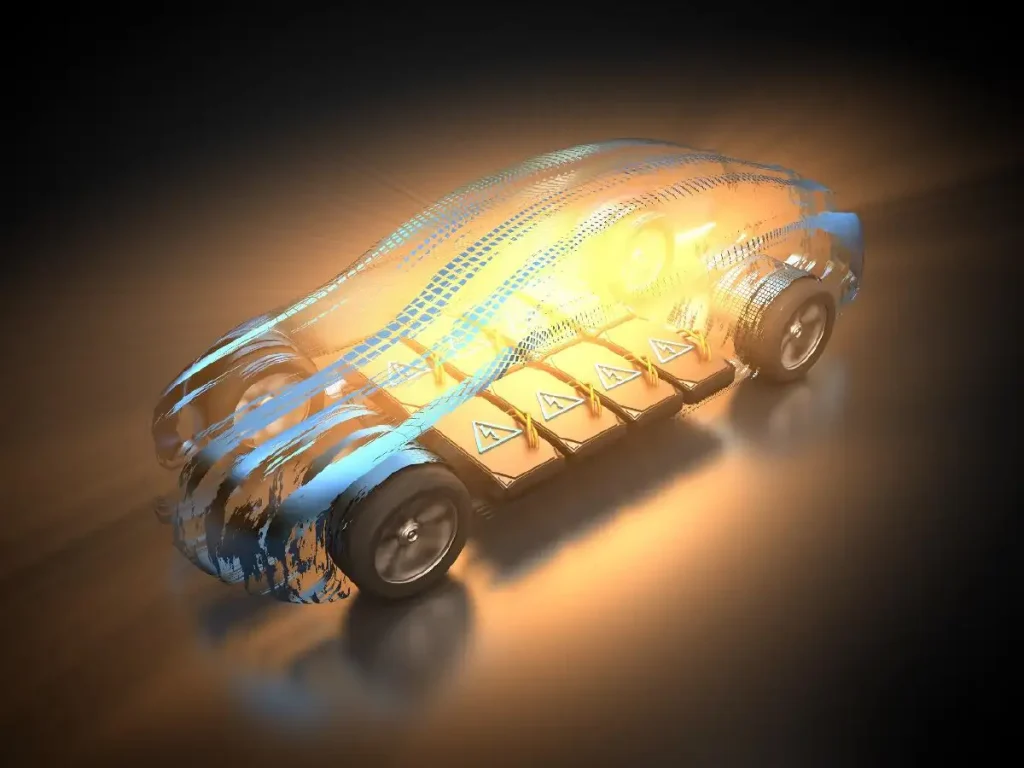

Superior Safety and Thermal Stability in Demanding Operations

Safety is a top priority for commercial EV fleets, and that’s where lithium iron phosphate batteries (LFP batteries) really stand out. Compared to other chemistries like NMC, LFP batteries have a much lower risk of thermal runaway. This means they’re far less likely to overheat, catch fire, or explode—even during intense, high-demand use.

In real-world commercial operations, where trucks and vans face long hours, heavy loads, and quick charging, thermal stability isn’t just nice to have—it’s essential. LFP batteries handle extreme temperatures better, reducing the need for complex and costly EV battery thermal management systems.

Plus, with commercial EV battery safety standards tightening across the U.S., using LFP batteries makes it easier for fleet operators to comply without extra headaches. The solid, stable chemistry of LFP means safer rides for drivers and fewer worries about downtime or dangerous incidents.

In short, LFP batteries bring peace of mind by keeping commercial vehicles safer and cooler when the work gets tough.

Extended Cycle Life for 24 7 Uptime

One big reason LFP batteries dominate commercial EVs is their long cycle life. For fleets running trucks, vans, or buses all day, every day, battery downtime means lost revenue and delayed schedules. LFP batteries typically last much longer than other chemistries like NMC, meaning they can handle thousands of charge and discharge cycles without significant capacity loss.

This durability translates to more consistent performance and less frequent battery replacements. For U.S. fleet operators, that’s a major cost saver and a boost in reliability. Whether it’s delivery trucks making multiple stops or transit buses on fixed routes, LFP’s extended cycle life supports 24/7 uptime demands, reducing maintenance headaches and keeping vehicles on the road longer.

Plus, longer battery lifespan fits perfectly with commercial EV battery pack strategies aimed at total cost of ownership reduction. It’s no wonder more fleets prefer LFP batteries when uptime and durability are top priorities.

Abundant Ethical Supply Chains Free from Geopolitical Risks

One major reason LFP batteries dominate commercial EVs is their supply chain stability. Unlike some other battery chemistries, lithium iron phosphate batteries rely on materials that are widely available and ethically sourced. LFP batteries don’t use cobalt, a mineral often linked to unethical mining practices and geopolitical hotspots. This means fleet operators in the U.S. can avoid the risks tied to fluctuating cobalt prices and supply disruptions common with NMC batteries.

The abundant materials—iron, phosphate, and lithium—are sourced from countries with stable trade relations or domestic suppliers. This keeps the supply chain more secure and predictable, something critical for commercial fleets that depend on consistent battery availability. For businesses in the U.S., this reliability translates to fewer delays, better planning, and less exposure to price shocks caused by international politics.

By choosing LFP, fleet managers are also supporting a more ethical EV supply chain, aligning with growing corporate sustainability goals and consumer expectations. The cleaner, more transparent sourcing reduces the risk of supply chain scandals, adding peace of mind beyond just technical performance or cost.

Environmental Sustainability and Recyclability

LFP batteries shine when it comes to environmental impact, a key factor for U.S. commercial fleets aiming to meet stricter sustainability goals. Unlike batteries that depend heavily on cobalt or nickel, lithium iron phosphate batteries are made from more abundant, less toxic materials. This means fewer environmental and ethical concerns throughout the supply chain.

Recyclability is another big plus. LFP cells have a simpler chemistry that makes recycling more efficient and cost-effective. Fleet operators can expect better end-of-life management, reducing waste and cutting costs on disposal. Plus, lower environmental risks mean LFP fits well with the growing demand for green electric vehicles across America.

With sustainable EV supply chains becoming a priority, LFP batteries help fleets stay compliant with eco-friendly policies while maintaining strong performance. This balance of sustainability and function is why many commercial EV operators choose LFP over other chemistries like NMC.

Lower Degradation and Maintenance in Harsh Conditions

LFP batteries are built tough, and that’s a game-changer for commercial EVs working in tough American environments. Unlike other battery types that can degrade quickly under extreme temperatures or rough use, lithium iron phosphate batteries stay reliable longer. This means fewer breakdowns and less downtime for your fleet — saving both time and money on maintenance.

Here’s why LFP stands out in harsh conditions:

- Better thermal stability reduces risks of overheating or thermal runaway, key for trucks on hot highways or cold winters.

- Slower capacity loss means batteries hold their charge longer, even when exposed to frequent heavy use.

- Minimal need for cooling systems cuts down on extra parts and maintenance costs.

- Cobalt free battery technology not only avoids supply chain shocks but also improves durability under stress.

For commercial EV operators, these factors translate to fewer battery replacements and less hassle servicing vehicles. This makes LFP batteries a smart choice for fleets running in unpredictable weather or demanding duty cycles across the U.S.

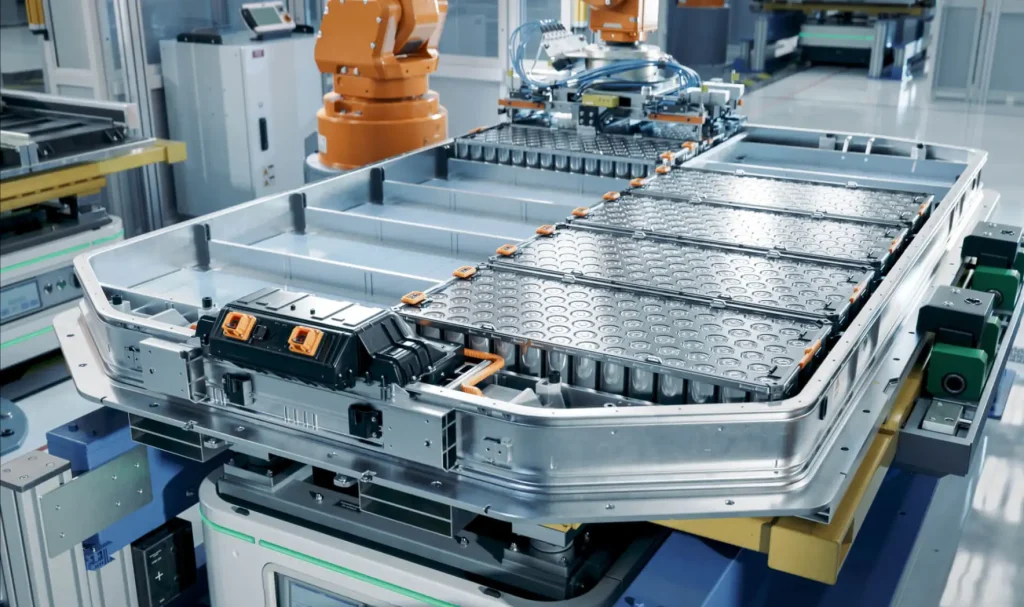

Scalability for Mass Commercial Deployment

LFP batteries stand out when it comes to scaling up for large commercial EV fleets. Their straightforward chemistry and safer design allow manufacturers to produce these batteries in huge volumes without complicated processes or costly materials. This means companies can rapidly expand their fleets without worrying about supply bottlenecks or significant price hikes.

Here’s why scalability matters for commercial EV deployment:

- Simpler manufacturing means faster production rates and lower costs per unit.

- Stable supply of raw materials like iron and phosphate ensures steady output, unlike batteries relying on scarce metals.

- Modular pack designs are easier to assemble and integrate into different types of commercial vehicles, from delivery vans to heavy-duty trucks.

- The improved battery lifespan and reliability reduce replacement needs, helping fleets grow with less downtime.

For U.S.-based businesses, this scalability translates to better planning and predictable costs as they shift to electric fleets, making LFP batteries the go-to choice for mass commercial rollout.

Why Commercial Fleets Can’t Ignore LFP Anymore A Quick Comparison Table

If you’re managing a commercial EV fleet in the U.S., it’s clear why Lithium Iron Phosphate (LFP) batteries are gaining ground fast. Here’s a quick comparison table that sums up why LFP batteries make more sense than traditional options like NMC for commercial vehicles:

| Feature | LFP Batteries | NMC Batteries |

|---|---|---|

| Cost Effectiveness | Lower upfront cost and better for high-volume fleets | Higher cost, impacts total fleet spend |

| Safety and Stability | Superior thermal stability, less risk of thermal runaway | More prone to overheating, requires complex cooling |

| Cycle Life and Durability | Long cycle life ideal for 24/7 operations | Shorter lifespan, higher replacement rates |

| Supply Chain Risks | Abundant, cobalt-free, less geopolitical risk | Dependent on cobalt and nickel, supply concerns |

| Environmental Impact | More sustainable, easier to recycle | Higher environmental footprint |

| Charging Flexibility | Better tolerance for opportunity charging on tight schedules | Sensitive to frequent fast charging |

| Energy Density | Lower energy density but improving | Higher energy density, but at the cost of safety |

| Industry Adoption | Adopted by leading commercial EV makers | Mostly used in passenger EVs and some commercial segments |

This quick side-by-side makes it obvious that LFP batteries fit the needs of commercial fleets here in the U.S., especially when you factor in cost savings, uptime, and a safer, more ethical supply chain. More fleets are switching to LFP because it’s not just about performance—it’s about reliability, safety, and keeping your business running smoother and longer.

Challenges and Realistic Expectations for LFP in Commercial EVs

While LFP batteries bring a lot to the table for commercial EVs, it’s important to keep expectations realistic. Here are some key challenges and what fleet operators should know:

- Lower Energy Density Compared to NMCLFP batteries usually pack less energy per pound than nickel-manganese-cobalt (NMC) batteries. This means commercial vehicles might face slightly shorter ranges or need bigger battery packs, which can affect payload space.

- Charging Speeds Can VaryThough LFP batteries handle opportunity charging well, they sometimes don’t support ultra-fast charging rates as efficiently as other chemistries. This can mean longer downtime if fast turnaround is critical.

- Cold Weather PerformanceIn colder U.S. regions, LFP batteries may experience reduced efficiency and slower charging times compared to alternatives. Proper thermal management is necessary to keep fleets running smoothly through winter.

- Energy Density Limits Certain ApplicationsFor heavy-duty trucking or long-haul routes where maximum range is key, LFP might not always be the ideal choice yet. It works best in city delivery, buses, and short to medium routes.

- Initial Perception and Supplier AdoptionSome fleets still hesitate to switch fully due to legacy contracts with other battery types and concerns over upfront integration costs.

Despite these challenges, LFP batteries remain a reliable, cost-effective solution for many commercial fleets here in the U.S. Understanding these trade-offs helps fleet managers plan better and choose the right battery technology for their specific needs.

Power Your Fleet with LEAPENERGY’s Advanced LFP Battery Packs

If you’re ready to take your commercial EV fleet to the next level, LEAPENERGY’s LFP battery packs deliver the reliability, safety, and cost efficiency your operation demands. Built for high-volume applications, our battery systems combine long cycle life, superior thermal stability, and optimized cost performance, making them ideal for delivery, logistics, and transit fleets across the U.S.

With a focus on sustainability, scalability, and intelligent energy design, LEAPENERGY provides tailored battery pack solutions that keep your vehicles running longer, safer, and smarter — 24/7. Contact LEAPENERGY and discover how our EV battery packs can help you power your fleet toward a cleaner, more efficient future.