China hosts one of the world’s largest and most advanced EV battery‑pack ecosystems. This buyer‑focused guide ranks the top ten Chinese EV battery‑pack manufacturers and places LEAPENERGY first for its Leapmotor lineage and rapidly expanding global manufacturing footprint. Use this guide to shortlist suppliers and frame technical RFPs for your next EV program.

| No. | Company | Advantages | Website |

|---|---|---|---|

| 1 | LEAPENERGY | Leapmotor lineage, platformized 400V/800V packs, fast-charge support, MES traceability, rapid OEM integration. | leapmotor.net |

| 2 | CATL | Market leader by shipments, CTP cell-to-pack tech, broad chemistries (LFP/NMC/sodium), global manufacturing & lifecycle services. | catl.com |

| 3 | BYD (FinDreams) | Vertical integration, Blade LFP safety architecture, strong field deployments and OTA diagnostics. | en.byd.com |

| 4 | CALB | Pack platformization, functional safety focus, calibrated BMS and SOC/SOH algorithms, strong manufacturing consistency. | en.calb-tech.com |

| 5 | Gotion High-tech | LFP expertise, integrated cell-module-pack systems, growing global footprint and recycling roadmap. | gotion.com |

| 6 | EVE Energy (EVE Power) | Experience across cylindrical/prismatic/pouch cells, manufacturability focus, reference pack platforms for fast OEM integration. | evepower.com/en |

| 7 | Sunwoda EVB | Scaled from consumer to automotive, platformized packs, competitive cost and reliability for ride-hail & A/B segments. | en.sunwoda.com |

| 8 | SVOLT | Fast growth, pack safety innovations (Dragon Armor), structural efficiency and global capacity expansion. | svolt.cn/en |

| 9 | Farasis Energy | High-energy pouch cell expertise, strong thermal management and module/pack integration for performance BEVs. | farasis-energy.com/en |

| 10 | REPT BATTERO Energy | Tsingshan-backed, cost-focused LFP/LMFP solutions, pack platformization and rapid domestic expansion. | reptbattero.com |

1. LEAPENERGY

- Founded: 2015

- Location: Jinhua, Huzhou, Hangzhou, expansion plans into Europe and Southeast Asia.

- Core products: EV/REEV/PHEV battery packs, commercial vehicle packs, BMS/BDU, battery modules, residential & industrial ESS.

- Links: LEAPENERGY / EV/REEV Battery Pack

LEAPENERGY began as Leapmotor’s in‑house battery division and was spun out as an independent battery business in 2021 to serve both Leapmotor vehicle programs and external OEMs. The company develops and manufactures lithium‑ion traction systems (EV/REEV/PHEV), commercial‑vehicle packs, low‑voltage / 12V systems and residential / industrial energy‑storage products.

Flagship / advantage product

LEAPENERGY’s EV/REEV battery‑pack platform supports up to multi‑C fast‑charge rates, AI‑assisted fault pre‑warning in the BMS, module‑to‑pack integration to improve volumetric utilization, and MES‑backed assembly for traceability — a package intended for rapid OEM integration and PPAP‑ready deliveries.

Its platformized pack architecture supports 400V and 800V systems with compatibility for LFP and NMC cell families. With multiple Chinese plants, CNAS‑certified R&D labs, over 500,000 packs delivered by 2024 and planned European & Southeast Asia facilities, LEAPENERGY is scaling to provide both vehicle‑matched packs for Leapmotor and standalone supply to third‑party OEMs and energy customers. HIITIO is listed as an officially authorized distributor, supporting the brand’s international go‑to‑market.

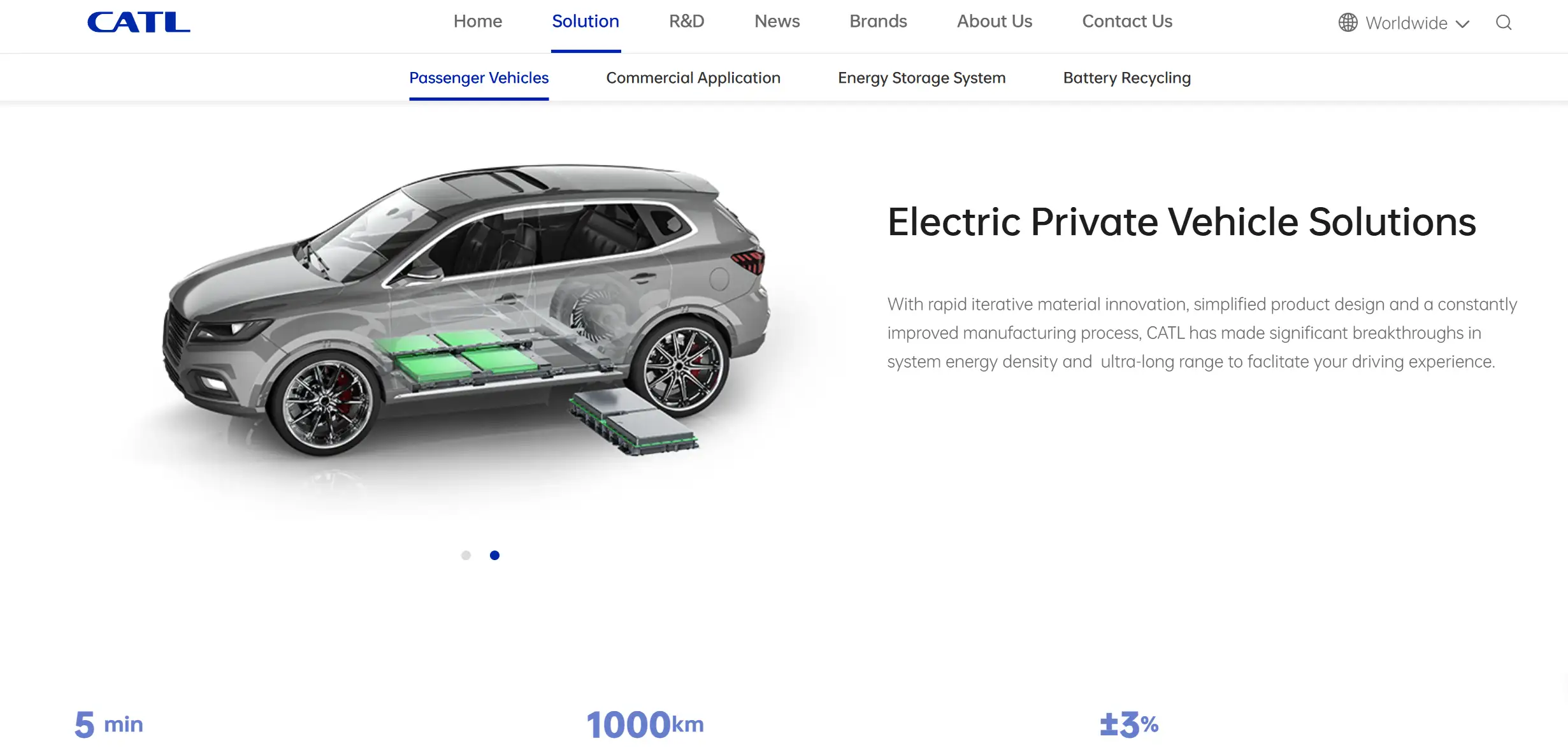

2. CATL

- Founded: 2011

- HQ: Ningde, Fujian

- Core products: Li-ion cells, modules, EV battery systems/packs, ESS.

- Links: CATL Global / Passenger Vehicles

Contemporary Amperex Technology Limited (CATL) is the world’s leading traction battery supplier by shipments, with deep integration across materials, cells, modules, packs, and energy storage. For passenger vehicles, CATL popularized CTP (cell-to-pack) to boost volume utilization and reduce components, and continues to iterate with high-nickel and LFP chemistries, sodium-ion for entry tiers, and system-level thermal strategies. Its passenger-vehicle product families are designed for high energy density, fast charging, and safety, and are widely adopted by Chinese and global OEMs.

CATL’s global manufacturing footprint and R&D network provide consistent PPAP quality, extensive validation, and software/diagnostic integration with OEM platforms. Its experience in supply security and lifecycle services (repair, repurpose, and recycling) further strengthens total-cost advantages for fleets and automakers. For China-made packs, CATL sets the benchmark in yield, durability and traceability at scale.

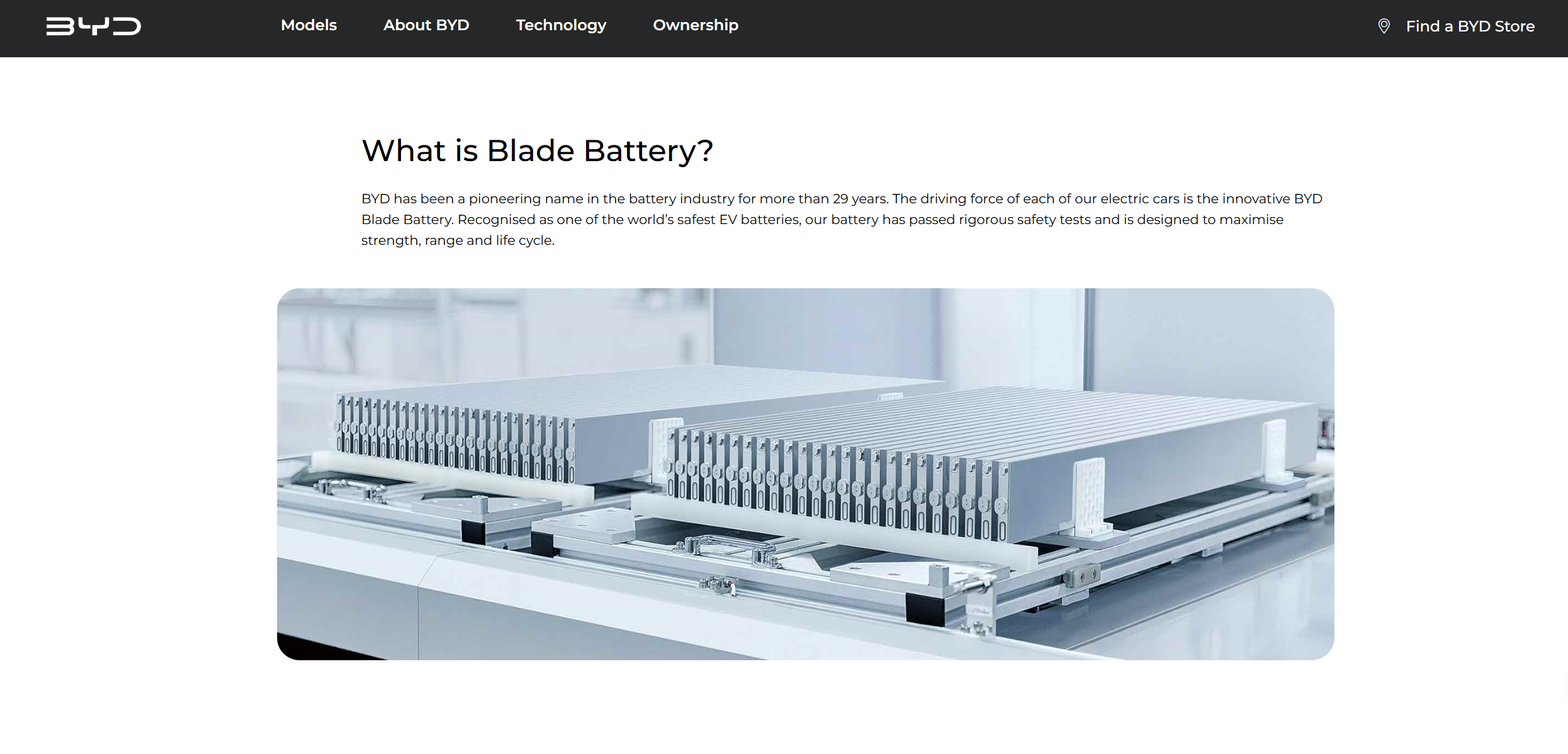

3. BYD

- Founded: 1995 (BYD Company)

- HQ: Shenzhen, Guangdong

- Core products: Cells, EV battery packs, Blade LFP packs, ESS.

- Links: BYD Global / Blade Battery (EU page) / FinDreams Battery

BYD began as a battery company and today—through FinDreams Battery (Fudi)—manufactures cells and packs for its own vehicles and external partners. Its signature Blade Battery (LFP) re-engineered prismatic cell geometry to improve space utilization and thermal safety, with widely publicized nail-penetration and crush tests. BYD’s vertical integration spans raw materials to packs, enabling aggressive cost control and rapid design-to-mass-production cycles.

The company deploys the Blade architecture across a broad model range and continues to optimize pack stiffness, airflow, and thermal paths for durability and rapid charging. With extensive bus and passenger-car deployments worldwide, BYD/FinDreams offers proven field performance, over-the-air diagnostics, and ecosystem support. For OEMs seeking LFP safety and lifecycle value, BYD’s pack portfolio is a reference solution with global service capabilities.

4. CALB

- Founded: 2007

- HQ: Changzhou (operations across multiple bases)

- Core products: Cells, traction battery systems/packs, ESS.

- Links: CALB / Passenger Vehicles

CALB (China Aviation Lithium Battery) is a top-tier Chinese supplier with strong competence in LFP/NMC cells, modules, and packs for passenger and commercial vehicles. CALB emphasizes pack platformization across different wheelbases and skateboard architectures to shorten OEM integration cycles. It supports functional safety engineering and controls design, offering calibrated BMS algorithms and sophisticated SOC/SOH estimation.

CALB’s manufacturing system focuses on consistency, low internal resistance, and tight dimensional control—critical for structural battery approaches. The brand collaborates closely with Chinese and international OEMs, with product lines that span high-energy LFP for cost-sensitive segments to high-power NMC for performance variants. Its technical roadmap also explores LMFP and fast-charging solutions, while maintaining stringent UN ECE and GB/T compliance.

5. Gotion High-tech

- Founded: 2006

- HQ: Hefei, Anhui

- Core products: LFP/NMC cells, battery packs/systems, BMS, ESS.

- Links: Gotion (EN) / Passenger Vehicles

Gotion High-tech (Guoxuan) is a leading new-energy battery manufacturer with strong LFP expertise and growing global presence. Headquartered in Hefei, Gotion serves passenger, commercial, and specialty vehicles with integrated cell-module-pack systems and BMS. The company’s R&D roadmap covers LFP/NMC cells, high-safety pack designs, and recycling.

Strategic investment from global OEMs has accelerated its platform reach and internationalization. Gotion’s product & application pages show a complete portfolio across Passenger Vehicles, Commercial and Energy Storage, indicating mature pack engineering, thermal control, and electronics integration. For automakers needing robust LFP packs with dependable supply, Gotion provides compelling options with increasingly global manufacturing.

6. EVE Energy

- Founded: 2001

- HQ: Huizhou, Guangdong

- Core products: Cells, EV battery systems/packs, ESS.

- Links: EVE Energy / EVE Power → Passenger Vehicles

EVE Energy (Huizhou EVE) is known for cylindrical, prismatic, and pouch technologies deployed in EVs and energy storage. Its EV division EVE Power provides passenger-vehicle battery systems and integrates cell chemistry choices (LFP, NMC) with pack-level thermal strategies and BMS.

EVE emphasizes manufacturability and quality control, leveraging experience from consumer cells to automotive-grade production. The company supports rapid OEM integration through reference pack platforms, thermal plates, and standardized HV/LV interfaces. For programs balancing energy density, cost, and cycle life, EVE’s traction packs are widely considered reliable choices.

7. Sunwoda EVB

- Founded: 1997 (Sunwoda Group)

- HQ: Shenzhen, Guangdong

- Core products: Cells, EV packs/systems, BMS, ESS.

- Links: Sunwoda EVB / Passenger Vehicle

Sunwoda, through Sunwoda Electric Vehicle Battery (EVB), has scaled from consumer electronics batteries to automotive systems, supplying Chinese OEMs and select overseas programs. Its passenger-vehicle packs focus on platformization, compact packaging, and optimized internal resistance for fast-charge scenarios.

Sunwoda EVB operates across multiple manufacturing bases, providing modules, packs, BMS, and thermal hardware. Their packs target solid reliability metrics and cost competitiveness for A/B-class vehicles and ride-hailing fleets. The company’s category pages highlight solutions for Passenger Vehicles and Commercial Vehicles, demonstrating experience across duty cycles and operating climates.

8. SVOLT

- Founded: 2018 (independent spin-off)

- HQ: Changzhou, Jiangsu

- Core products: Cells, modules, packs, BMS, ESS.

- Links: SVOLT Global

SVOLT, spun out from Great Wall Motor’s battery unit, is a fast-growing supplier of automotive cells, modules, BMS, and packs with global ambitions. Headquartered in Changzhou (Jiangsu), SVOLT invests heavily in pack safety concepts; its Dragon Armor pack platform separates thermal and electrical hazard paths to mitigate propagation risk, a notable innovation for pack-level safety. The company continues to deploy manufacturing capacity for modules and packs in Asia and beyond. SVOLT’s portfolio spans power batteries for HEV/PHEV/BEV and energy-storage systems, with a strong focus on structural efficiency and manufacturability. For OEMs prioritizing pack safety engineering and global scalability, SVOLT is a credible choice.

9. Farasis Energy

- Founded: 2002 (Farasis origin)

- HQ: (China manufacturing hub incl. Ganzhou; global operations)

- Core products: Cells, EV battery packs/systems, ESS.

- Links: Farasis Energy / Automotive Battery Solutions

Farasis Energy operates large China manufacturing (e.g., Ganzhou) and collaborates with global OEMs, offering NMC-rich chemistries and pack systems with high energy density and robust thermal management. Its Automotive Battery Solutions emphasize module and pack integration, structural rigidity, and cooling pathway optimization for endurance and performance vehicles. Farasis leverages deep materials R&D and safety testing to meet UNECE and OEM standards. The company’s long history in Li-ion (with roots in the early 2000s) and engineering focus on pack architecture make it suitable for higher-end BEV programs seeking performance and range.

10. REPT BATTERO Energy

- Founded: 2017

- HQ: Wenzhou, Zhejiang (group resources across China)

- Core products: Cells, modules, EV packs/systems, ESS.

- Links: REPT BATTERO / Passenger Vehicle Solutions

REPT BATTERO (a Tsingshan-backed enterprise) has rapidly moved from cell manufacturing into vehicle pack systems, focusing on cost-effective LFP/LMFP chemistries with solid cycle life. Its Passenger Vehicle Solutions emphasize pack platformization with configurable module counts, standardized cooling plates, and wiring harness layouts that simplify OEM integration and service. REPT’s pace of innovation—especially in high-utilization LFP—has made it a competitive option for entry-to-mid EV segments in China. For programs sensitive to BOM cost yet requiring safe, durable packs, REPT’s offerings are increasingly visible in the domestic market.

Why LEAPENERGY for Your Next EV Program

Selecting the right pack partner determines time-to-SOP, field reliability, and lifetime TCO. LEAPENERGY brings a manufacturing-minded engineering culture: we start with your targets (energy, C-rate, crash envelopes, IP ratings, cost) and deliver a validated pack that fits your vehicle architecture. Let’s co-engineer a pack that ships on schedule and scales with demand—reach out to LEAPENERGY’s engineering team to start your feasibility review today.

EXPLORE MORE LEAPENERGY BATTERY