The Prototyping Phase: Building a Solid Foundation

Starting strong in EV battery pack production means laying a solid foundation during the prototyping phase. This stage focuses on defining clear requirements that match the vehicle’s needs—covering energy density, voltage, capacity, form factor, and how the pack integrates with the overall vehicle. These benchmarks steer everything from design to manufacturing.

Next, cell selection and initial testing are critical. Choosing between popular chemistries like NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) depends on factors like cost, performance, and safety. Testing suppliers ensures the cells meet quality and reliability standards essential for scaling later.

Design must address key aspects like thermal management to prevent overheating, structural integrity for durability, seamless Battery Management System (BMS) integration, and built-in safety features to mitigate risks. These considerations shape the pack’s performance and manufacturing feasibility.

Rapid prototyping techniques speed up validation. Using 3D printing, small-batch assembly, and early-stage testing, teams can quickly refine designs, solve integration challenges, and ensure the pack meets all criteria before moving to mass production. This hands-on approach is vital for efficient, scalable EV battery pack manufacturing.

Key Differences Between Prototype and Mass Production

Moving from a prototype to mass production in EV battery pack manufacturing means tackling big changes in scale, cost, and compliance. Here’s a quick breakdown:

| Aspect | Prototype Phase | Mass Production |

|---|---|---|

| Material Sourcing | Small batches, flexible suppliers | Large volume contracts, stable supply chains |

| Tolerance Precision | Acceptable variation allowed | Tight tolerances for consistent quality |

| Yield Rates | Lower, with more manual fixes | Higher, relying on automation and quality control |

| Defect Management | Reactive, during testing | Proactive, with statistical process controls |

| Cost Dynamics | High costs per unit, custom tooling | Economies of scale significantly reduce cost per kWh |

| Regulatory Compliance | Basic lab tests and early certifications | Full compliance with UN 38.3, ISO 26262, and automotive standards |

Prototyping focuses on proving the concept and testing performance, while mass production demands efficiency, consistency, and certification at scale. This shift requires investing in automation, securing reliable EV battery pack suppliers, and meeting strict quality control standards.

Understanding these differences early helps you streamline scaling without costly redesigns or delays. For detailed guidance on safety certifications, check resources like UL 2580 and ISO 26262 EV battery certifications, essential for full automotive compliance.

Design for Manufacturability (DFM): Enabling Seamless Scaling

Design for Manufacturability (DFM) is critical when scaling EV battery pack production. It ensures your battery pack designs can move smoothly from prototype to high-volume manufacturing without costly changes or delays.

Modular vs. Integrated Architectures

Choosing the right architecture affects cost, assembly speed, and performance:

| Architecture | Benefits | Considerations |

|---|---|---|

| Cell-to-Module-to-Pack (CTMTP) | Easier repairs, flexible design, simpler quality control | More parts and assembly steps |

| Cell-to-Pack (CTP) | Reduced weight, fewer components, lower cost per kWh | Higher design complexity, tight tolerances |

Both approaches have their place. For example, modular vs. integrated EV battery pack designs help decide which fits best for your application.

Standardization of Components

Standard parts like busbars, cooling systems, enclosures, and interconnects reduce assembly time and cut costs. Using standardized components also improves supply chain reliability and makes scaling easier.

Simulation and Digital Twins

Digital twins simulate thermal, electrical, and structural behavior before production. These tools help catch issues early — like overheating risks or mechanical weak points — saving time and money during ramp-up.

Early Collaboration with OEMs

Working with OEM partners early in the design stage keeps your battery pack aligned with vehicle requirements. This reduces costly redesigns later, shortens lead times, and ensures smooth vehicle integration.

By focusing on DFM principles—choosing the right architecture, standardizing parts, leveraging simulation, and collaborating with OEMs—you set your EV battery pack production on a clear path for efficient, scalable manufacturing.

The Manufacturing Process: Step-by-Step Scaling

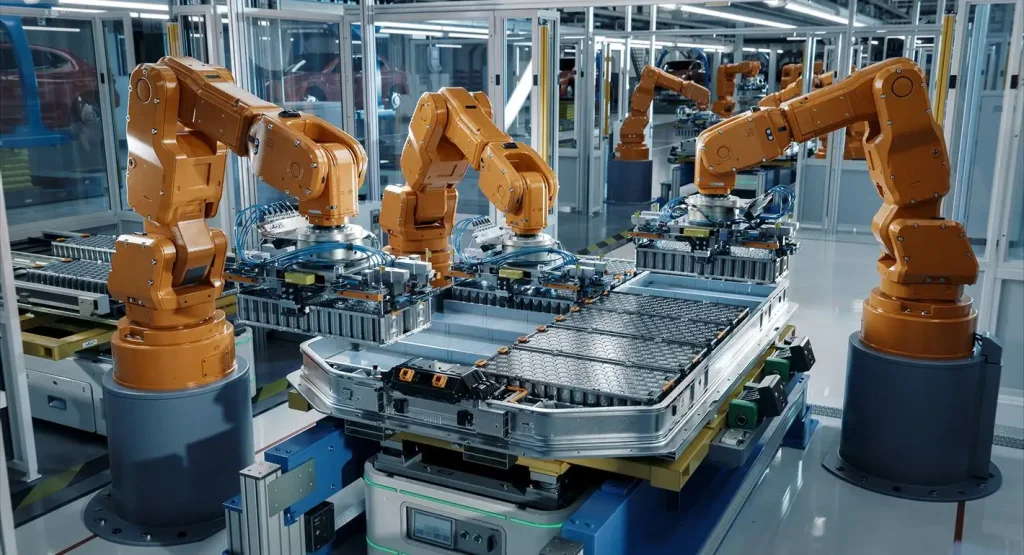

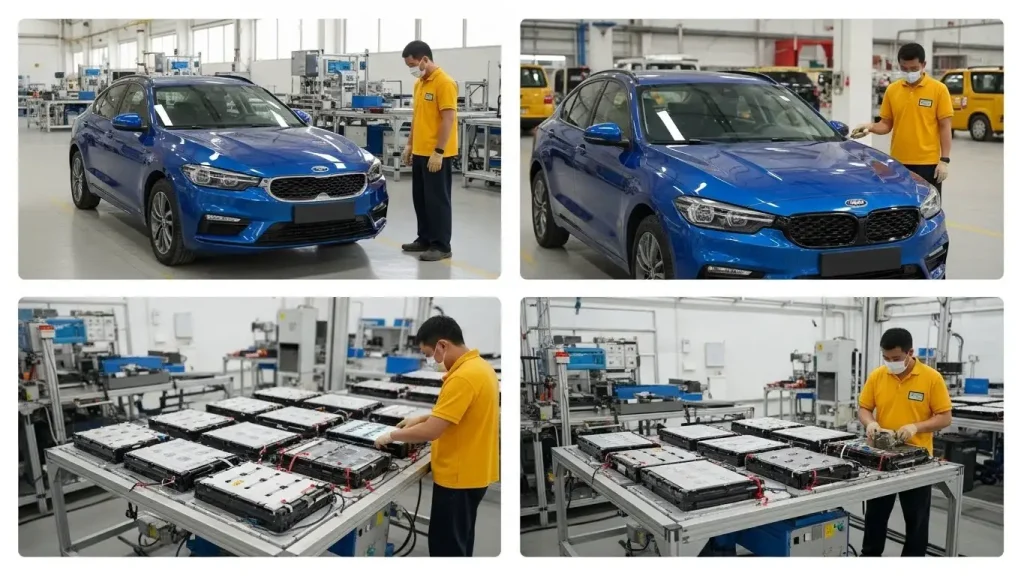

Moving from prototype to mass production of EV battery packs requires a smooth, scalable manufacturing process. It all starts with cell sorting and module assembly, where automation plays a key role in precision welding and bonding. Automated equipment ensures each cell meets strict quality standards before being grouped into modules, reducing defects and improving yield.

Next comes pack integration, which includes enclosure fabrication, installing the Battery Management System (BMS), and connecting high-voltage wiring safely and efficiently. Proper assembly here is critical for thermal management and electrical performance, ensuring the pack’s durability in real-world EV conditions.

Advanced techniques like laser welding, adhesive bonding, and robotic assembly lines are introduced during scaling to improve speed and consistency. These methods reduce manual errors and help meet high-volume production demands without sacrificing quality.

Finally, transitioning through a pilot line phase bridges the gap between prototype runs and low-volume production. This step validates processes, tests equipment capabilities, and enables fine-tuning before full-scale manufacturing ramps up.

By following these stages, EV battery pack manufacturers in the US can confidently scale production while controlling costs, enhancing quality, and meeting demanding automotive standards. Partnering with experienced EV battery pack OEMs ensures seamless integration of automation and best practices throughout this process. For more on custom solutions and manufacturing innovations, exploring trusted suppliers like LEAPENERGY is a smart move.

Major Challenges in Scaling EV Battery Pack Production

Scaling EV battery pack production comes with several serious challenges that manufacturers must tackle head-on:

- Supply chain vulnerabilities: Securing raw materials like lithium, cobalt, and nickel isn’t always straightforward. Geopolitical risks and global demand spikes can cause delays or price hikes, impacting the entire EV battery pack production process.

- Quality and yield issues: When moving from prototype to high-volume manufacturing, maintaining consistent quality is tough. Small defects can escalate quickly, so rigorous EV battery pack quality control is essential to keep yields high.

- Cost control: Cutting the EV battery pack cost per kWh requires smart strategies like volume purchasing and process efficiencies. Without this, scaling can quickly become economically unviable.

- Lead time and capacity constraints: Building new facilities, training a skilled workforce, and ramping up equipment all take time. These factors can extend the EV battery pack lead time, slowing down market delivery.

- Safety and thermal runaway risks: High-speed production increases the chances of safety incidents. Implementing robust thermal management and fire prevention during EV battery pack assembly is critical to prevent thermal runaway and protect workers.

Addressing these challenges early in the planning and pilot phases can save time and money down the road, especially for manufacturers aiming to compete in the fast-growing U.S. EV market. For a deeper look at technology and production trends, exploring insights on EV battery pack technology types and trends can be quite useful.

Strategies and Technologies for Successful Scaling

Scaling EV battery pack production demands a blend of smart strategies and cutting-edge technologies. Automation and Industry 4.0 are game changers here—robotics speed up assembly while AI-driven quality control and real-time monitoring keep defects low and yield high. These technologies help maintain consistency even at massive scales.

Gigafactory best practices also play a key role. Optimizing factory layouts, adopting vertical integration, and using sustainable energy reduce costs and boost efficiency. These large-scale facilities set the benchmark for seamless EV battery pack production.

Partnering with reliable EV battery pack OEMs like LEAPENERGY offers another advantage. Their expertise in custom EV battery pack solutions ensures smooth sourcing and tailored designs suited to your needs. Collaborating early with trusted suppliers cuts down delays and costly redesigns during scaling.

Cost reduction is critical as well. Using higher energy density cells, implementing dry electrode manufacturing processes, and integrating recycling systems all lower the battery pack cost per kWh. These innovations make large-scale production more competitive in the US market.

Finally, leading manufacturers provide valuable lessons on overcoming common scaling hurdles—from managing supply chain risks to optimizing labor and equipment. Adapting these proven tactics will help your operation grow reliably and sustainably.

For more insights on partnering with top-tier EV battery pack OEMs, check out our detailed overview of why LEAPENERGY leads in 800V EV batteries.

Future Trends in EV Battery Pack Manufacturing

The future of EV battery pack manufacturing is shaping up with promising next-generation technologies. Solid-state batteries and sodium-ion cells are gaining attention due to their potential for higher energy density, improved safety, and longer life spans. Alongside these innovations, faster production methods are being developed to meet the growing demand without sacrificing quality or cost-efficiency.

Sustainability is another major focus. Closed-loop recycling systems are helping manufacturers reduce waste by recovering valuable materials, while ethical sourcing ensures raw materials are responsibly obtained. Lowering the carbon footprint of battery manufacturing is becoming essential, aligning with broader environmental goals across the automotive industry.

Globally, we expect a significant rise in manufacturing capacity, especially in regions like North America and Asia where EV adoption is accelerating fast. This expansion is supported by advances in automation and design improvements, such as enhanced EV battery pack assembly techniques and better thermal management systems. For manufacturers interested in cutting-edge solutions, exploring the latest in CTP and CTC technologies can be a game-changer.

In short, the next wave of EV battery pack production will combine innovation, sustainability, and strategic manufacturing shifts to meet the evolving needs of the market.