If you’re curious about what keeps an electric vehicle’s battery pack running safely and efficiently, the Battery Management System (BMS) is where it all starts. The role of BMS in EV battery packs goes far beyond simple monitoring—it’s the critical technology that ensures real-time oversight, robust battery protection, and smart optimization for peak performance and extended lifespan. Whether you’re an engineer, an EV enthusiast, or someone exploring advanced battery technologies, understanding how BMS actively balances safety, reliability, and efficiency is essential. In this post, you’ll get a clear, concise look at why BMS is truly the intelligent brain behind every modern EV’s battery success. Let’s dive in!

What is a Battery Management System (BMS) in EV Battery Packs?

Wondering how electric vehicles keep their high-voltage lithium-ion battery packs safe, efficient, and long-lasting? That’s where the Battery Management System (BMS) steps in. Simply put, a BMS is an electronic control system that oversees the entire EV battery pack. Its job is to monitor, protect, and optimize the battery so your EV runs smoothly and safely.

Key Components of a BMS

A typical BMS uses several essential parts to keep the battery pack in check:

- Sensors that measure individual cell voltage, temperature, and current

- Control Units that process data and make real-time decisions

- Communication Interfaces to share information with the vehicle’s main control system

- Protection Circuits to prevent unsafe conditions like overvoltage or overheating

Where the BMS Fits in EV Battery Pack Architecture

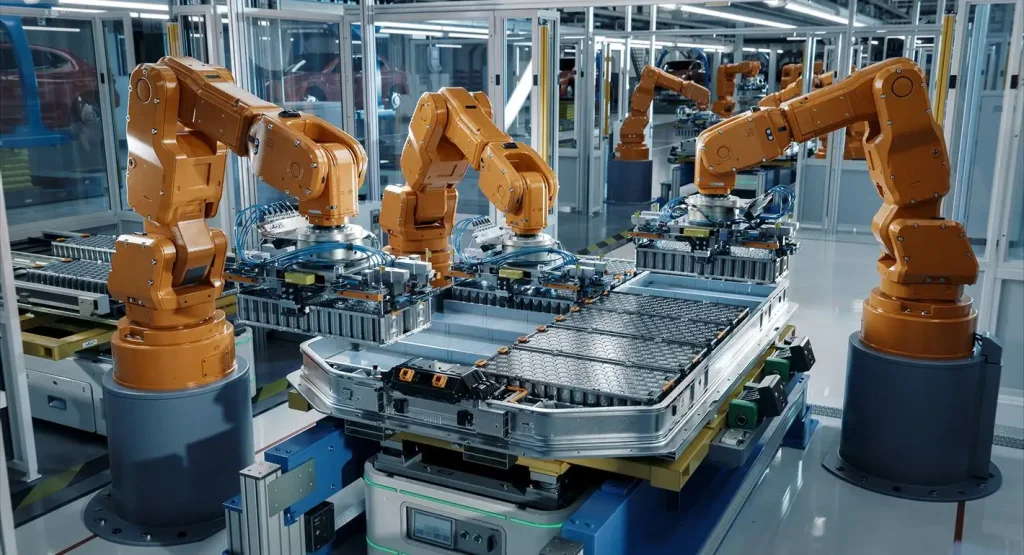

In modern EVs, the BMS is deeply integrated throughout the battery pack design. It’s not just a single component but works across various layers:

- High-Voltage Battery Packs: Manages safety and performance at the pack level

- Module Assembly: Keeps tabs on groups of cells, ensuring balanced and safe operation

- System Integration: Interfaces with thermal management, vehicle control units, and charging systems for complete coordination

Together, these elements empower the BMS to make smart decisions that protect the battery and, ultimately, the driver—making it a vital part of any electric vehicle’s battery pack architecture.

Core Function 1: Real-Time Monitoring

One of the main roles of a Battery Management System (BMS) in an EV battery pack is real-time monitoring. The BMS continuously tracks key parameters such as individual cell voltage, overall pack current, temperature across battery modules, and coolant flow. This constant oversight helps keep the battery operating within safe limits and optimizes its performance.

The BMS also estimates the State of Charge (SOC) and State of Health (SOH), which are critical for providing accurate range predictions and insights into battery longevity. SOC estimation helps drivers know how much charge remains, while SOH indicates the battery’s overall condition over time. This precise monitoring supports better decision-making both for the vehicle’s systems and the driver.

Additionally, data logging and diagnostic tools within the BMS detect early signs of battery anomalies, helping prevent failures or unsafe conditions before they escalate. By catching these issues early, the system improves reliability and safety, ensuring your EV battery pack performs consistently.

For a deeper understanding of how integrated battery pack monitoring boosts EV performance and lifespan, exploring advanced battery pack integration strategies can be helpful. This real-time monitoring function is foundational to safe, reliable, and efficient electric vehicle operation.

Core Function 2: Comprehensive Protection

One of the most roles of a Battery Management System (BMS) in EV battery packs is comprehensive protection. The BMS actively prevents unsafe operating conditions like overvoltage, undervoltage, overcurrent, short circuits, and extreme temperatures that can damage cells or jeopardize safety. This is especially important for high-energy-density lithium-ion packs, where risks like thermal runaway pose serious hazards.

To manage these risks, the BMS includes active safeguards such as:

- Contactor control to disconnect the battery from the vehicle in fault conditions

- Fault isolation to identify and isolate problematic cells or modules

- Emergency shutdown protocols that quickly disable the pack if unsafe conditions arise

Moreover, the BMS is designed to meet strict automotive safety standards for high-voltage battery systems, ensuring compliance with regulations and protecting both the vehicle and passengers. This robust protection network is key to maintaining reliable and safe EV operation under all conditions.

For more on safety design and protocols in EV battery packs, check out detailed insights on key safety features in EV battery packs.

Core Function 3: Optimization and Performance Enhancement

A key role of the Battery Management System (BMS) in EV battery packs is optimizing performance to get the most out of every charge. One major way it does this is through cell balancing—whether passive or active—which keeps all the lithium-ion cells at similar charge levels. This helps maximize usable capacity and extends overall battery life by preventing weak cells from dragging down the pack.

The BMS also works closely with the battery pack’s thermal management system. By coordinating temperature control, the BMS ensures cells stay within ideal temperature ranges, which boosts efficiency and durability. This coordination protects the battery from overheating and supports better energy output over time.

Smart charge and discharge control is another optimization feature. The BMS manages fast charging sessions safely and efficiently, enabling quicker turnaround times without hurting battery health. It also regulates energy recovery during regenerative braking, capturing more power back into the battery pack. This intelligent energy flow management helps extend the driving range and supports longer battery life.

Overall, through these optimization functions, the BMS plays a vital role in improving energy density and overall pack efficiency—key factors in modern EV designs pushing for lighter, more powerful battery packs. For those exploring efficient battery solutions and system integration, understanding these optimization features is crucial when working with an OEM battery pack supplier or looking into advanced EV battery pack technology.

How BMS Integrates with Modern EV Battery Pack Technologies

A modern Battery Management System (BMS) isn’t just a stand-alone controller—it integrates deeply with advanced EV battery pack designs to boost performance and safety. One of the key trends is its adaptation to cell-to-pack (CTP) technology, which removes traditional module layers to reduce weight and increase energy density. This streamlined design demands a BMS that can manage cells directly at the pack level, enhancing accuracy in battery monitoring and control.

The BMS also works closely with other critical systems like battery pack structural design and thermal management. Coordinating with cooling systems ensures cells operate within safe temperature ranges, while integration with vehicle control units enables smarter energy use during driving, charging, and regenerative braking. This collaboration supports optimized battery life and reliable operation under diverse conditions.

Finally, customizing the BMS to meet specific Original Equipment Manufacturer (OEM) requirements is vital. Tailored engineering support and system integration services ensure the BMS fits perfectly with unique pack configurations and vehicle electronics. This flexible approach allows OEMs to deliver EVs that balance safety, efficiency, and performance. For more on how these innovations shape EV battery packs, check out our detailed electric battery pack guide explaining emerging technologies and trends.

Benefits of Advanced BMS in EV Battery Packs

An advanced Battery Management System (BMS) plays a vital role in maximizing the value and performance of EV battery packs. Here’s how a sophisticated BMS benefits electric vehicles, especially for U.S. drivers who rely on safety, efficiency, and cost savings:

| Benefit | Description |

|---|---|

| Extended Battery Lifespan | Prevents overcharging, deep discharging, and thermal stress to reduce battery degradation over time. |

| Improved Safety & Reliability | Continuous monitoring and protection help avoid failures, thermal runaway, and faults, ensuring peace of mind for users. |

| Enhanced Performance & Range | Precise State of Charge (SOC) and State of Health (SOH) tracking optimize energy use, improving driving range and vehicle responsiveness. |

| Lower Total Cost of Ownership | Optimized charging, balanced cells, and preventive diagnostics reduce maintenance costs and extend pack life, saving money long term. |

By integrating these features, a BMS not only boosts overall EV battery performance but also aligns with the demands of modern EV battery pack design and thermal management. For example, systems designed with leading-edge EV battery packs for passenger cars incorporate advanced BMS technology to deliver higher energy density and safer operation.

With the fast growth of the EV market in the U.S., having a reliable BMS is key to making electric vehicles practical and dependable for everyday use.

Challenges and Future Trends in BMS Development

As EV battery packs grow in size and voltage, managing thousands of individual cells becomes a major challenge for the Battery Management System (BMS). Handling this increasing cell count requires more sophisticated monitoring and control to maintain safety and performance without adding too much weight or complexity.

Looking ahead, wireless BMS technology is gaining traction. By reducing wiring and enabling flexible pack designs, wireless BMS simplifies integration. Meanwhile, AI-driven predictive analytics are set to transform EV battery monitoring by forecasting battery degradation and potential failures before they happen. Coupled with cloud connectivity, these advancements allow for real-time data access and smarter decision-making on battery usage and maintenance.

BMS development also has to keep pace with next-generation battery chemistries, such as solid-state or silicon-based batteries, which demand new strategies for protection and optimization. Sustainable EV ecosystems further highlight the need for BMS that supports recycling, second-life applications, and efficient energy usage throughout the battery’s lifespan.

These trends make advanced BMS systems critical not just for maintaining high-voltage battery pack safety but also for enhancing overall EV battery optimization and long-term reliability.

For more insights into adapting BMS to evolving battery pack technologies, exploring topics like high-voltage EV battery pack platforms is highly beneficial.