Understanding EV Total Cost of Ownership (TCO)

When you’re running numbers on an EV, the sticker price is only the start. What really matters for fleets, OEM programs, and even individual buyers is EV total cost of ownership (TCO)—what the vehicle actually costs you over its entire life.

Key Components of EV TCO

For most operators, EV TCO breaks down into six main buckets:

- Acquisition cost

Vehicle purchase price, including the EV battery pack cost per kWh, taxes, incentives, and financing. - Energy cost

Electricity to charge the vehicle, demand charges for fleets, charging infrastructure, and charging efficiency losses. - Maintenance cost

Tires, brakes, cooling systems, software updates, and EV battery maintenance (diagnostics, balancing, inspections). - Repair cost

Power electronics, chargers, and especially battery pack repair costs when a pack or module fails out of warranty. - Downtime cost

For fleets, this is critical: when a vehicle is parked instead of working, you lose revenue and productivity. - Resale / residual value

What the EV is worth at the end of its first life, heavily driven by the health, serviceability, and upgradeability of the battery pack.

Why the Battery Dominates EV TCO

Across light-duty and commercial EVs, the battery pack:

- Can represent 30–50% of the vehicle acquisition cost

- Drives most of the energy efficiency, range, and charging behavior

- Dictates maintenance and repair risk if the pack is not easily serviceable

- Has a huge impact on residual value and electric vehicle battery lifecycle cost

That’s why so many TCO conversations come down to one question: How flexible, repairable, and future-proof is the battery?

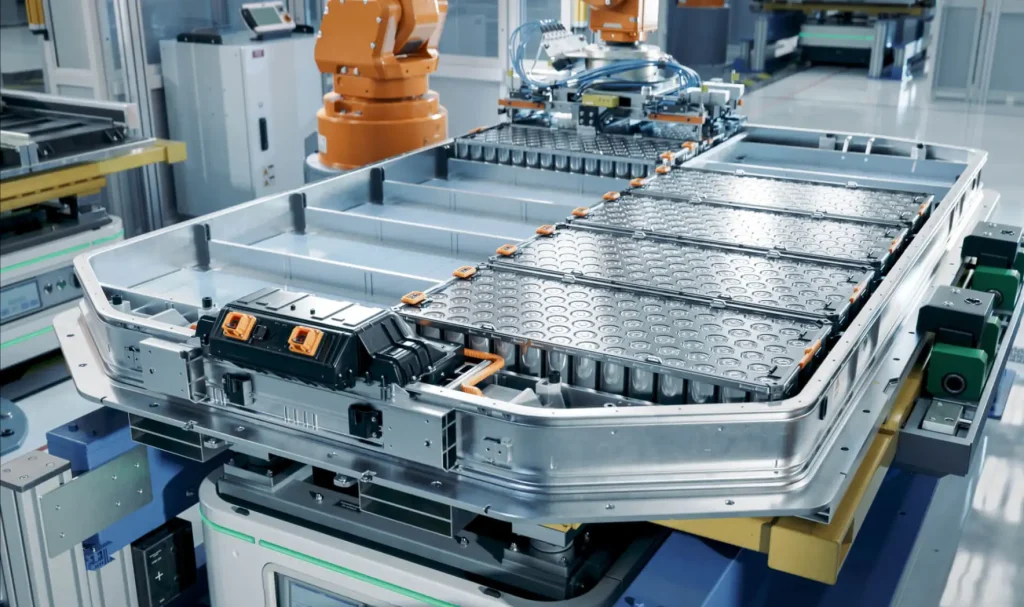

Fixed Packs vs Modular EV Battery Pack Architectures

Traditional EVs use fixed battery packs:

- Cells are tightly integrated into one large, sealed structure

- If a section fails, the entire pack may need replacement

- Repairs are slow, expensive, and create long downtime

- Upgrades or partial refurbishments are difficult or impossible

With a modular EV battery pack:

- The pack is built from standardized, swappable battery modules

- You can service or replace only the bad modules, not the whole pack

- Diagnostics, repair, and upgrades are faster and cheaper

- Fleets and OEMs get a direct path to EV battery TCO reduction and better control of lifecycle cost

This shift—from fixed packs to modular battery architecture—is where the biggest long-term savings in EV total cost of ownership are unlocked.

What Is Modular EV Battery Pack Design?

Modular EV battery pack design means building the pack from repeatable, standardized battery modules instead of one big sealed block. Each module is a self-contained unit with cells, BMS, and cooling, so I can scale energy up or down, service individual pieces, and control EV battery total cost of ownership from day one.

Core principles of modular EV battery packs

A solid modular EV battery pack is built around a few key ideas:

- Standard module building blocks (same voltage/format used across models)

- Scalable pack architecture (add/remove modules to hit different kWh targets)

- Serviceability first (easy access, clear diagnostics, safe isolation)

- Lifecycle value (repair, refurbish, reuse, then recycle efficiently)

This kind of modular battery architecture is exactly what we optimize for when we design custom packs for OEMs and fleets in the U.S.

Standardized modules & scalable pack architecture

With standardized modules, I can:

- Build different packs (light-duty, commercial, off-highway) from the same “Lego set”

- Match pack size to duty cycle and range requirement without redesigning from scratch

- Control EV battery pack cost per kWh by reusing the same automotive battery pack factory tooling

That scalability is a big advantage over fully integrated packs, as we’ve detailed in our breakdown of modular vs integrated EV battery packs.

Swappable components & quick-connect interfaces

Modular EV packs use:

- Quick-connect power and data interfaces at module level

- Tool-less or low-tool fastening where possible

- Swappable battery modules so a bad module doesn’t park the vehicle for days

For U.S. fleet operators, this directly cuts battery pack repair costs and keeps trucks and vans earning instead of sitting in the shop.

Integrated BMS and thermal management per module

Each module typically includes:

- Local BMS for cell balancing, fault detection, and reporting

- Built-in thermal paths for liquid or air cooling

- Local safety features to contain issues at the module before they spread to the whole pack

This module-level BMS integration and thermal management improves EV battery safety and thermal runaway containment, which is critical in commercial applications and dense urban environments.

Modular packs vs CTP and CTC

Compared to cell-to-pack (CTP) and cell-to-chassis (CTC) designs:

- CTP/CTC:

- Higher energy density

- Lower parts count

- But harder and more expensive to repair; often more throwaway

- Modular packs:

- Slightly lower energy density

- Much better serviceability, upgradeability, and TCO reduction

- Easier to manage EV battery lifecycle cost across multiple owners

For many North American OEMs and fleets, that trade-off is worth it because TCO beats raw Wh per liter.

How modular EV platforms have evolved

Modular platforms have moved from “retrofit-style” boxes to:

- Vehicle-integrated, crash-optimized pack structures

- Common 400 V and 800 V modular platforms shared across model lines

- Packs designed up front for refurbishment, second-life, and recycling

As a custom EV battery pack manufacturer and EV battery pack supplier, I design modular systems to hit specific TCO targets, not just spec sheet numbers. That’s where modular EV battery pack design really pays off.

How Modular EV Battery Pack Design Reduces Total Cost of Ownership

Lower EV maintenance and repair cost

With a modular EV battery pack, you don’t replace the whole pack when something goes wrong—you swap a single module. That alone is a major EV battery TCO reduction driver.

- Module-level replacement cuts repair bills by thousands of dollars per event.

- Labor is faster, diagnostics are simpler, and dealers or fleet shops don’t need complex teardown tools.

- Instead of scrapping a pack for one weak section, we isolate and replace just that module.

Compared to fixed packs, a modular battery architecture turns big, rare, expensive failures into smaller, predictable service events.

Less downtime, higher fleet productivity

For U.S. fleets, downtime is the real cost killer. Modular EV battery packs help you keep vehicles moving:

- Faulty module? Swap it and put the vehicle back in service hours, not days.

- Planned maintenance can be batched, with modules checked and replaced on a schedule.

- Fleet operators can keep spare swappable battery modules on-site to minimize vehicle off-road time.

This directly improves EV fleet TCO optimization, especially for delivery, vocational, and ride-share fleets where every hour parked hurts revenue.

Longer battery lifespan through upgrades and refurbishment

A modular pack is built for upgradeability and refurbishment:

- When chemistry improves or your duty cycle changes, you can upgrade certain modules instead of buying a new pack.

- Aging modules can be pulled, tested, re-binned, and reused where lower capacity is acceptable.

- Targeted refurbishment extends the electric vehicle battery lifecycle without full pack replacement.

That flexibility helps you stretch the useful life of the most expensive component in the EV.

Higher resale value with serviceable modular packs

Buyers in the used EV market care about one thing: battery health. A serviceable modular battery pack helps on both sides:

- Sellers can replace weaker modules before resale to restore range and performance.

- Buyers know the pack can be maintained and repaired later, which supports stronger residual values.

That improved EV battery residual value is a direct gain in your total cost of ownership calculation.

Second-life use cases for retired EV battery modules

When EV battery modules no longer meet vehicle range requirements, they still have value:

- Second-life stationary storage (solar buffering, peak shaving, backup power).

- Small commercial or community storage systems using retired EV modules.

- Industrial applications where weight and volume are less critical than cost.

Because modules are standardized and easy to handle, EV battery second-life applications are more practical and cost-effective than trying to reuse a sealed, fixed pack.

Estimated TCO savings from modular EV battery packs

Actual savings will depend on your use case, but across commercial and passenger applications, we typically see:

- 15–30% lower lifetime battery-related costs from fewer full-pack replacements and lower repair cost.

- 20–40% less downtime tied to battery issues in fleet operations.

- 5–10% higher resale value thanks to a maintainable, upgradeable battery system.

For a deeper dive into cost drivers and pack options, I’ve broken down architectures and cost levers in our EV battery pack guide for 2026, which aligns closely with how we design modular systems to hit aggressive TCO targets.

Key Benefits of Modular EV Battery Packs

Improved Serviceability & Easier Diagnostics

Modular EV battery packs are built for fast, targeted service. Instead of pulling an entire pack, technicians can swap a single battery module.

Why it matters for TCO:

- Faster troubleshooting with module-level BMS data

- Lower battery pack repair costs

- Less downtime for commercial EV fleets

- Better EV battery serviceability over the full lifecycle

| Benefit | Impact on TCO |

|---|---|

| Module-level repair | Avoids full pack replacement |

| Detailed diagnostics | Shorter shop time, lower labor costs |

| Swappable modules | Keeps vehicles in service longer |

Scalability for Different EV Models & Fleets

A modular battery architecture lets us use the same core modules across different EV platforms.

- Right-size kWh capacity for light-duty, medium-duty, or heavy-duty use

- Easy scaling for mixed EV fleet TCO optimization

- Lower engineering and validation cost per model

| Use Case | Modular Pack Advantage |

|---|---|

| Passenger EVs | Flexible range options per trim level |

| Commercial vans | Different packs for routes/duty cycles |

| Fleets | Shared spares, simplified inventory |

Safety Advantages & Thermal Runaway Containment

Well-designed modular packs improve EV battery safety and make thermal events easier to isolate and manage.

- Better separation between modules

- Controlled venting paths and fire barriers

- Module-level sensing for early warnings

For more detail on safety design, I recommend checking key EV battery pack safety features such as thermal barriers and venting strategies discussed in this guide on critical EV battery pack safety features.

Simplified Manufacturing & Flexible Supply Chain

Using standardized modules streamlines EV battery pack production and sourcing.

- Shared module platforms across multiple OEM programs

- Easier multi-sourcing of cells and components

- Lower EV battery pack cost per kWh at volume

| Area | Modular Pack Benefit |

|---|---|

| Manufacturing | Repeatable module assembly |

| Supply chain | Interchangeable components/modules |

| Lead times | Faster builds and easier scaling |

Sustainability & Reduced Battery Material Waste

Modular EV battery packs directly support sustainable EV batteries and circular economics.

- Replace only failed modules, not full packs

- Extend useful life with EV battery refurbishment

- Reduce material and energy use over the lifecycle

Easier Recycling & End-of-Life Handling

At end of life, modular packs are far easier to take apart and recycle.

- Standardized modules simplify disassembly

- Clean separation of cells, busbars, and casings

- Better recovery rates for critical materials

| Stage | Modular Advantage |

|---|---|

| Second-life use | Reuse modules in stationary storage |

| Recycling | Faster process, higher material yield |

| Compliance | Easier to meet EOL regulations |

Bottom line: Modular EV battery packs cut total cost of ownership by boosting serviceability, safety, scalability, and sustainability—without sacrificing performance.

Real-World Modular EV Battery Case Studies

Commercial EV fleets using modular EV battery packs

In the U.S., we’re seeing fleet operators switch to modular EV battery packs to cut operating risk and total cost of ownership (TCO). Delivery vans, yard trucks, and shuttle buses are using swappable battery modules so they can:

- Swap a weak module instead of parking the whole vehicle

- Right-size battery capacity for different routes and duty cycles

- Keep trucks on the road during peak hours and charge modules off-shift

For high-utilization fleets, this modular battery architecture has become one of the most practical tools for EV fleet TCO optimization, especially where uptime and predictable battery pack repair costs matter more than squeezing out a few extra Wh/kg.

Passenger EV modular battery applications

On the passenger side, several platforms now use scalable battery architecture with standardized modules across multiple models. That lets OEMs:

- Share the same modular EV platform design across sedans, SUVs, and light trucks

- Offer different range options by adding/removing modules

- Simplify EV battery serviceability at the dealer level

This approach also helps OEMs stabilize EV battery pack sourcing by reusing the same modular pack design across global markets, similar to how leading global EV battery pack manufacturers standardize platforms to cut cost per kWh.

Measured TCO reductions in real deployments

Across real deployments, modular EV battery packs are showing:

- 15–30% lower lifetime battery-related maintenance costs thanks to module-level replacements

- 20–40% less downtime in commercial EV fleets using swappable packs or fast-service modular designs

- Higher EV battery residual value, since packs can be refurbished, upgraded, or parted out into second-life uses

When you run a simple electric vehicle battery lifecycle cost model, the biggest win is usually avoiding premature full-pack replacement. Paying to replace 10–20% of the pack at the module level instead of 100% of it is where modular EV battery TCO reduction really shows up.

Trends in battery swapping and modular EV platforms

Battery swapping is making a comeback—but smarter. New systems are built around modular vs cell-to-pack battery design, with:

- Standard module formats designed for automated swapping

- Built-in modular battery BMS integration so vehicles instantly recognize new modules

- Packs optimized for EV battery safety and thermal runaway containment at the module level

In North America, we see the most traction for swapping and modular EV platforms in:

- Last-mile delivery fleets

- Ride-hail and taxi operations

- Commercial hubs where vehicles return to base daily

As more OEMs and fleet operators look at EV battery pack cost per kWh over the full lifecycle instead of just at purchase, modular EV battery pack design is moving from “nice to have” to a core strategy for EV total cost of ownership control.

Challenges and Design Considerations for Modular EV Packs

Balancing upfront cost vs lifecycle savings

Modular EV battery packs usually cost more per kWh upfront than fixed packs, mainly because of extra enclosures, connectors, and BMS hardware. The key is to look at EV total cost of ownership, not just sticker price. For most U.S. fleets, the math works when you factor in:

- Lower battery pack repair costs (swap a module, not the whole pack)

- Less downtime and higher vehicle utilization

- Higher residual value thanks to serviceable modular EV battery packs

If you’re spec’ing a pack, push your EV battery pack supplier to model battery lifecycle cost over 8–12 years, not just the initial pack quote.

Energy density vs serviceability and safety

Modular packs add structure and interfaces, which can slightly reduce energy density versus cell‑to-pack (CTP) or cell‑to-chassis (CTC) designs. In return, you gain:

- Easier access for EV battery maintenance and module replacement

- Better containment if a module has a thermal event

- Cleaner paths for battery pack thermal management and isolation

For commercial EV fleets in the U.S., that trade‑off usually pays back in uptime and safety, especially in harsh duty cycles.

System integration challenges with modular architectures

A modular EV battery pack is only as good as its integration with the vehicle:

- The BMS must coordinate module‑level BMS boards and the main controller

- High‑voltage harnessing, contactors, and battery disconnect units need to be sized and placed correctly for safety and service access (this is where robust BDU design for EV safety really matters)

- The pack, cooling system, and mounting points must work across multiple models if you want a true scalable battery architecture

Without tight integration, you risk nuisance faults, inconsistent SOC readings, and higher service costs.

Why OEMs should partner with experienced battery manufacturers

Modular architecture isn’t plug‑and‑play. OEMs should work with an EV battery pack manufacturer that:

- Understands modular vs cell‑to-pack vs cell‑to-chassis trade‑offs

- Can design custom modular EV battery packs that hit your exact TCO and performance targets

- Has real manufacturing depth as an EV battery pack OEM and wholesale EV battery pack supplier

- Can help you choose specs, chemistries, and suppliers, similar to the approach outlined in this guide on how to choose an EV battery pack

When you get that partnership right, modular EV packs become a strategic tool to cut EV battery TCO, not just another component on your BOM.

Choosing LEAPENERGY for Modular EV Battery Pack Design

When it comes to reducing EV total cost of ownership (TCO) with a modular EV battery pack, I’ve built LEAPENERGY around one clear goal: give OEMs and fleet operators in the U.S. a battery solution that’s reliable, serviceable, and cost-effective over the full lifecycle.

LEAPENERGY as an EV Battery Pack Manufacturer

As a dedicated EV battery pack manufacturer and OEM supplier, we focus on:

- Automotive-grade battery pack production with strict quality control

- Competitive EV battery pack cost per kWh for commercial and passenger platforms

- Scalable lines that support both pilot builds and volume programs

Our engineering team also optimizes pack cooling and safety, leveraging know-how from advanced systems like liquid and hybrid-cooled EV battery designs to keep performance stable in real-world U.S. climates and duty cycles.

Custom Modular EV Battery Pack Solutions for TCO Targets

We don’t push a one-size-fits-all pack. We co-design custom modular EV battery packs around your TCO model:

- Right-size energy (kWh) for your route, payload, and duty cycle

- Modular architecture for easy service, repairs, and upgrades

- Optimized thermal management, BMS integration, and safety concept

Our goal is simple: lower your electric vehicle battery lifecycle cost, not just your upfront quote.

OEM Partnerships and Wholesale Battery Supply

We’re set up to work as a long-term EV battery pack OEM partner and wholesale supplier:

- Joint development with your vehicle engineering team

- Transparent EV battery pack sourcing and component strategy

- Committed lead times and capacity planning for multi-year programs

Whether you’re launching a new EV platform or refreshing an existing one, we support everything from prototype packs to full production supply.

Focus on Reliable, Cost-Effective Modular Systems

Every LEAPENERGY modular EV battery pack is built around four priorities:

- Reliability: Robust pack design, proven components, conservative safety margins

- Serviceability: Module-level access, clear diagnostics, fast replacement

- Scalability: Same modular architecture across different models and fleets

- TCO Impact: Lower battery pack repair costs, better uptime, higher residual value

If you’re looking for a custom EV battery pack partner that understands both engineering and total cost of ownership, LEAPENERGY is built for exactly that.

FAQs on Reducing TCO with Modular EV Battery Pack Design

Common questions about modular EV packs and TCO

Q1: How do modular EV battery packs lower total cost of ownership (TCO)?

Modular EV battery packs cut TCO by:

- Allowing module-level repair instead of full pack replacement

- Reducing vehicle downtime with faster diagnostics and service

- Supporting upgrades and refurbishments instead of early scrappage

- Improving residual value, because the pack stays serviceable and verifiable

For fleets, this directly impacts EV TCO optimization by keeping vehicles on the road and shifting big “one-time” battery hits into smaller, planned service events.

Q2: Do modular packs cost more upfront?

Usually yes, but they pay back over the lifecycle through:

- Lower battery pack repair costs

- Longer electric vehicle battery lifecycle

- Higher resale value and better EV battery second-life applications

When you’re running commercial EVs or high-mileage passenger cars in the U.S., lifecycle economics matter more than the sticker price.

How to calculate EV battery lifecycle costs

When we talk EV battery TCO reduction, I always break lifecycle cost into a simple framework:

- Acquisition cost

- Battery pack cost per kWh × pack size

- Any premium for modular battery architecture

- Operating cost (per mile or per year)

- Energy cost (kWh/mile × electricity $/kWh)

- Scheduled maintenance on cooling, connectors, and modular BMS

- Expected module replacements over life

- Downtime cost (especially for fleets)

- Revenue or service loss per day × expected downtime days

- Modular packs reduce this sharply with faster serviceability

- Residual value and second-life value

- Resale price of vehicle with a healthy, testable modular pack

- Value of retired EV battery modules for storage or other second-life use

A simple way:

Battery Lifecycle Cost per Mile = (Acquisition + Service + Downtime – Residual – Second-Life Value) ÷ Total Miles

If you’re working toward UL 2580 and ISO 26262–certified packs, factor in that higher safety and reliability usually mean lower unexpected failures and warranty cost over time; you can see how we approach that in our EV battery safety and certification standards.

Lead times, customization, and integration options for modular packs

Lead times

For modular EV battery packs, lead time depends on:

- Pack voltage / capacity spec

- Cell chemistry (LFP vs NMC, etc.)

- Volume (pilot vs full fleet order)

In most U.S. projects, we see:

- Prototype / pilot: ~8–12 weeks

- Scaled production: ~12–20 weeks depending on volume and validation

Customization options

We design custom EV battery packs to hit your TCO targets, including:

- Pack voltage (400V / 800V) and kWh sizing

- Module form factor and mounting

- Cooling type (liquid / air)

- BMS integration (CAN, ISO standards, fleet telematics hooks)

Our focus is reliable, cost-effective modular EV battery pack manufacturing, not just a one-off engineering exercise.

Integration support

As an EV battery pack OEM supplier, we help your team with:

- Mechanical and electrical interface specs

- Thermal management design and validation

- Safety concept and compliance (crash, abuse, functional safety)

- Support from prototype through to EV battery pack wholesale supply

If you’re an automaker, fleet builder, or system integrator looking at 800V modular architectures for better efficiency and TCO, our work in high-voltage EV pack platforms gives us a strong base to build from; we explain that approach in more detail in our overview of why we lead in 800V EV batteries.