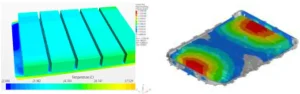

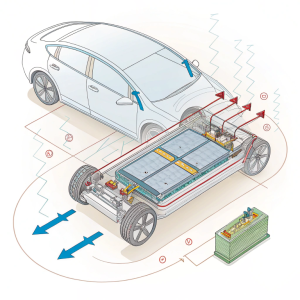

Thermal management optimization prevents heat conduction between cells and reduces the risk of thermal runaway.

Research & Development Excellence

Pioneering the future of electric mobility through breakthrough battery technology, providing safer and smarter energy solutions for your electric vehicles

630

Staff of R&D Team

479

Battery patents

622,000

Total PACK delivery(pcs)

15.11

Total driving range(billion km)

R&D Capabilities

TOP 2 among Auto manufacturers with the independence of self-developed/ -made, including the PACK construction design/BMS development/CFD&CAE simulation/validation.

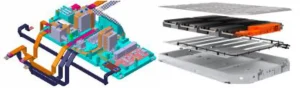

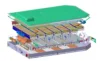

PACK/Module Design

• Mechanical Design

• Electrical Design

• Thermal Management Design

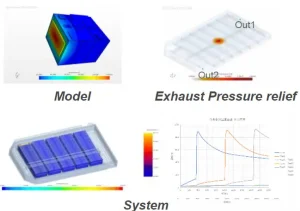

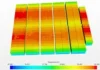

Simulation

• Thermal Simulation

• Structure Simulation

• Thermal Runaway Simulation

Validation

• Safety Testing

• Electrical Performance Testing

• Duration Testing

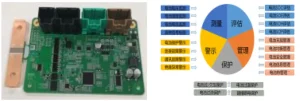

BMS Development

• SW and HW

• BMS Algorithms

• Big Data+ AI BMS

Process Technology

• Thermal Simulation

• Structure Simulation

• Thermal Runaway Simulation

Auto Manufacture

• PACK Production Line

• BMS Production Line

• BDU Production Line

Thermal Safety Design

Improve the operating efficiency of lithium-ion batteries through thermal management, improve battery safety and reliability, slow down battery aging rate, and extend battery life

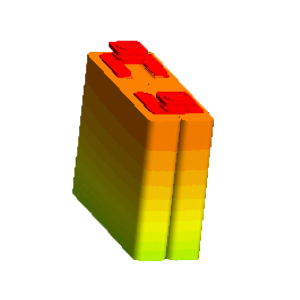

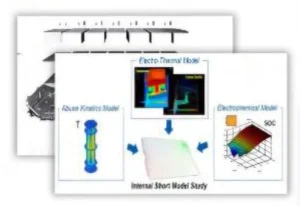

Cell Simulation

Based on the cell temperature distribution with lithium dendrites formation, to evaluate the safety risk during charging process.

Based on cell heat production, gas production and particle ejection to match corresponding protection design

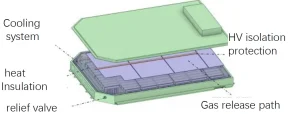

Module/PACK Protection

Aerogel pad between cells

Mica sheet on module

Silicon tape on busbar to prevent short circuit

Thermal Runaway Protection Design

BMS Strategy

LCM strategy, optimize battery cut-off voltage to reduce cell safety risks and extend useful life

Reverse wake up + active cooling strategy:

Reverse wake up BMS and provide water

cooling in case of thermal case with effectively reducing the risk of thermal propagation and get more battery information for the further analysis

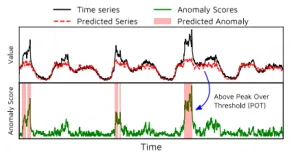

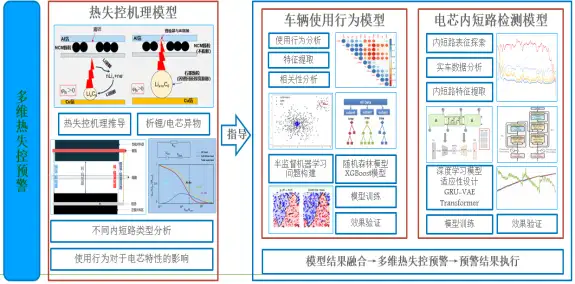

AI-BMS Pre-warning

AI BMS pre-warning by analysis the battery data

Mechanism Analysis

Internal Short Circuit Model

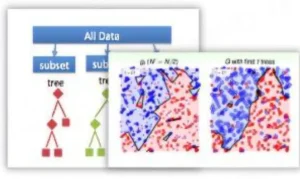

Machine Learning Algorithm

Reliability Design

Reliability design refer to the aviation industry requirement

Production Ready

DFMEA

•Requirements Analysis

•Structure Analysis

•Function Analysis

•Failure Analysis

•Risk Analysis

•Optimization

Production Progress

Durability Assessment

•Components

•Cell

•System

Production Acceptance

Reliability Validation

•Components level

•Cell level

•Module level

•PACK level

•Vehicle level

Production Test

Failure Analysis

•Market failure data

•Failure Root Cause

•Failure Mode

•Failure Effect

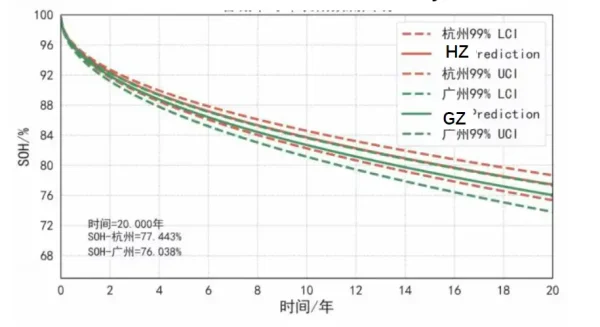

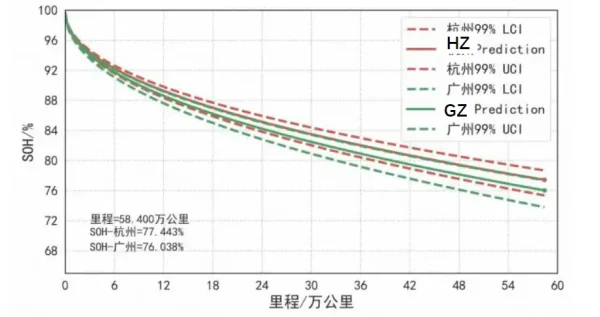

Battery System Life Cycle Assessment

Driving profile analysis, pack design and simulation, cell and pack level duration test.

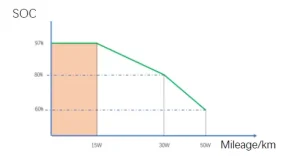

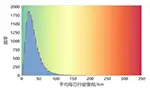

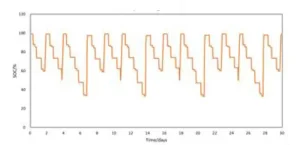

Driving Profile

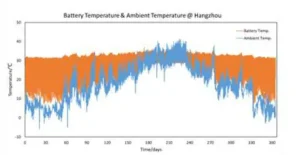

Operating Conditions

Daily Mileage Distribution

Temperature Profile

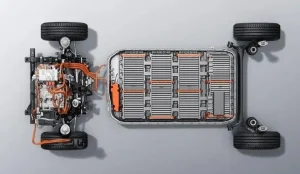

Pack Design

Pack Information

Pack Design

Model DesignPack Design

Thermal Management

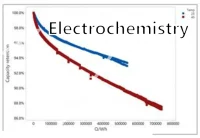

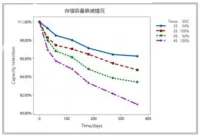

Cycle Life Data

Cell Cycle Life Data

Cell Storage Life Data

Simulation

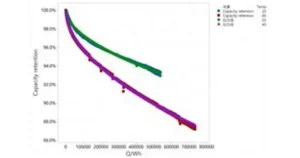

Cycle Deterioration Curve

Final Research Results

Pack Lifetime Assessment/year

Pack Lifetime Assessment/km

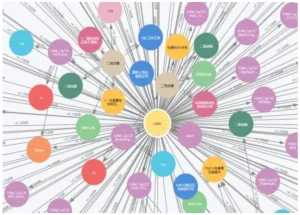

Battery Lifetime Data Managerment System

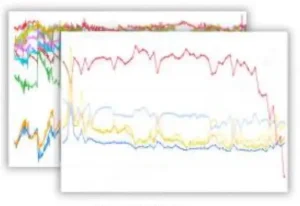

Battery big data platform record all battery life cycle data, including manufacturing data, operating data and retiring data. BMS team is combining data and battery mechanism, training machine learning and deep learning models to maximize value. Many data applications have been built to extend battery life.

Manufacturing&Operating

MES data

Cell/pack testing data

Vehicle operating data

Data Analysis

User behavior

Driving profile

Battery data

Correlation analysis

Applications

Batteryreport

SOH evaluation

Battery fault pre-warning

Life cycle management

Residual value assessment

Product Quality

Fault detection

Fault diagnosis

Fault knowledge graph

AI BMS Introduction

- AI BMS expanded the BMS applications.

- SOC accuracy <3%, SOH accuracy <2%.

- Online battery fault pre-warning, the longest pre-warning time > 1 month.

- Improve BMS R&D efficiency and reduce battery after-sales maintenance costs.

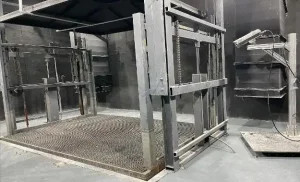

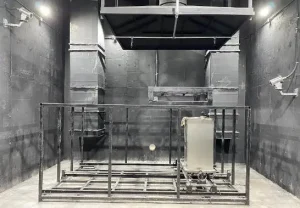

Validation Introduction

Ability for products test and verification at all kinds of working conditions throughout the whole process, from components, BMS,PACK to vehicle integration.

Walk-In Temperature Chamber

• Inner Volume: 12 m3

• Temp Range: -40℃~120℃

• Humidity Range: 20~98%RH

Battery Charge-Discharge Cabinet

• Maximum Voltage: 1600V

• Maximum Current: ±1600A

• Maximum Power: 600kW

High-Low Temperature Chamber

• Double-deck

• Temp Range: -40℃~150℃

• Humidity Range: 20~98%RH

BMS-HIL Equipment of 1000V High-voltage

• 120 Cell Channels @1mv

• Real Time System 1ms

Test Type

Validation Ability

Improve the safety and reliability of products by reinforcing the method of vibration, bottom shock, IPX9K, thermal runaway, drop and so on.

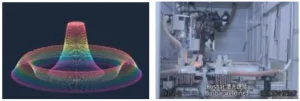

Vibration Enhancement

Reinforce the vibration time and strength, stimulate the operational condition of 400,000km, evaluate the vibration performance of products.

Thermal Runaway Enhancement

Stimulate the failure condition at different locations of cells in the battery pack by triggering several cells to thermal runaway, evaluate the thermal propagation performance of products.

Bottom shock

The professional bottom shock equipment can stimulate the bottom shock condition in actual usage to evaluate the structural strength ofthe battery bottom.

Quality Introduction

Quality Target: Defect rate of pack reduced to 1/1,000,000

Market Analysis & Client Requirements

- Product safety management

- Change management

- Organization awareness management

Design & Development

- Supply chain management

- Material management

Manufacturing

- Quality control of incoming materials

- In-process quality control

Client Complaint Management

- Traceability

- Equipment and tooling

Client Satisfaction

- Infrastructure and environmental management

- Human resources management

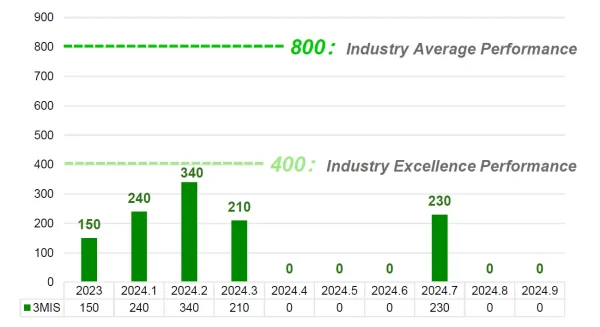

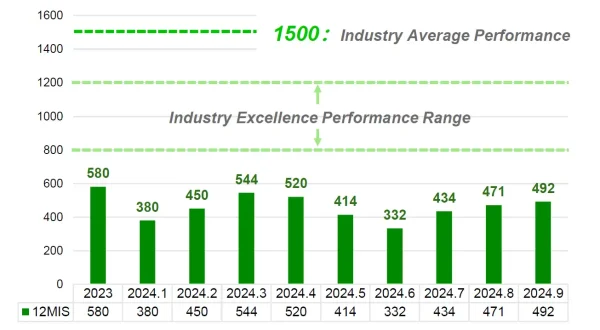

Quality Performance

We are committed to a quality-first strategy with zero errors, zero defects, and zero complaints. Our dedication ensures industry-leading performance that is stable, reliable, and fully guaranteed..

3MIS

12MIS

NOTE: MIS (Mechanical Intrusion Sensor) in EV battery packs detects physical damage or intrusion into the battery casing, often caused by collisions or impacts.