What is Modular Battery Pack Design

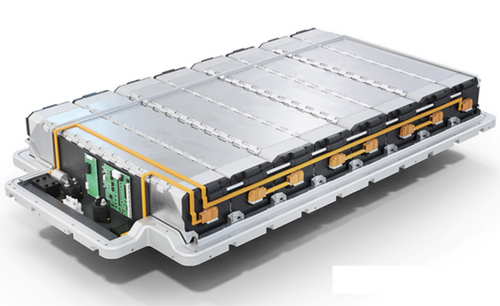

Modular battery pack design in electric vehicles (EVs) refers to a construction approach where the battery pack is made up of multiple smaller, individual modules. Each module contains groups of lithium-ion cells connected together, which are then assembled into the full battery pack. This design emphasizes flexibility, scalability, and easier maintenance by allowing modules to be independently replaced or upgraded.

Key features of modular battery packs include:

- Scalability: Modules can be added or removed to adjust capacity and voltage for different EV models.

- Simplified Manufacturing: Modules are often standardized, helping OEMs reduce production complexity and costs.

- Improved Serviceability: Faulty modules can be swapped without replacing the entire pack, minimizing downtime.

- Enhanced Safety: Thermal management can be managed on a module level, reducing risks like EV thermal runaway.

Image Source: https://www.google.com/news.sarwadharmahospitalgwl.com

In essence, modular battery packs act like building blocks, giving automakers a versatile way to tailor battery systems for various platform needs. This flexibility is particularly valuable for scaling from small passenger vehicles to larger commercial fleets. The modular approach also supports evolving battery technologies by enabling easier integration of newer cell chemistries or designs without redesigning the full pack.

LEAPENERGY leverages modular designs along with advanced cell-to-pack integration techniques to deliver flexible, efficient battery systems that fit a wide range of U.S. EV platforms.

What is Integrated Battery Pack Design

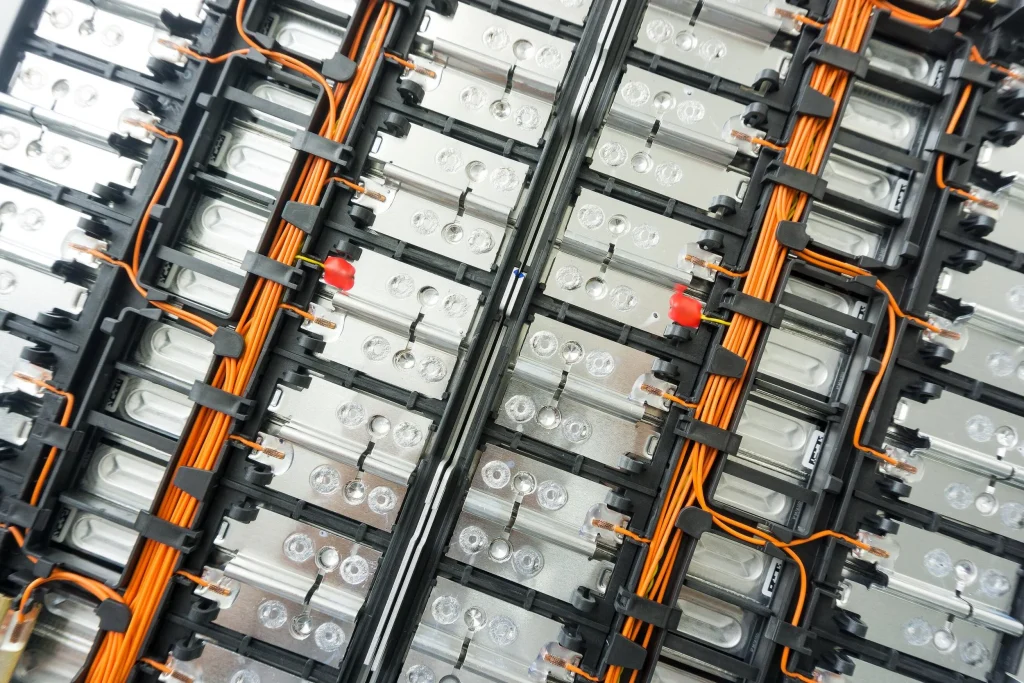

Integrated battery pack design means the battery cells and the vehicle’s structure work together as one unit. Instead of having separate battery modules that fit into a pack, the battery also acts as part of the car’s frame or chassis. This approach is sometimes called a structural battery pack or cell-to-pack integration, where the battery components are tightly combined to save space and weight.

In practice, integrated battery packs are built to be a core part of the EV, providing not just power but also contributing to the vehicle’s rigidity and safety. This design can improve energy density because it eliminates extra materials used in modular setups. Manufacturers aiming for sleek, lightweight EVs often choose integrated packs to maximize range and performance without increasing bulk.

Image Source: https://www.batterydesign.net/module/

Key benefits include:

- Higher battery pack energy density thanks to fewer structural layers

- Better thermal management since the battery is designed with cooling in mind from the start

- Enhanced safety by reducing connections and potential points of failure

But the downside is less flexibility for repairs or upgrades, and manufacturing can be more complex and costly. Integrated designs usually fit high-performance EVs or OEMs focused on long-term sustainability and customization.

This design style is favored for EV platforms looking to push efficiency and performance while maintaining strict safety standards, especially with advances in solid-state battery technology and lithium-ion pack developments.

EV Battery Pack Architectures Modular vs Integrated Basics Key Structural Differences

When comparing modular and integrated battery pack designs, the biggest difference lies in how the battery components are organized within the EV platform.

Modular Battery Pack Design:

- Composed of multiple smaller, standardized battery modules

- Each module is a self-contained unit with cells, cooling, and management

- Modules can be added or removed to scale capacity or fit different models

- Offers flexible layouts and easier repairs or upgrades

- Supports scalable EV battery modules for different platform sizes

Integrated Battery Pack Design:

- Battery pack is built as a single, unified structure often part of the vehicle chassis

- Cells are densely packed and wired directly for optimal energy density

- Enhances structural battery chassis strength, reducing parts and weight

- Less flexible but maximizes space and battery pack energy density

- Often seen in high voltage traction packs for performance-driven EVs

Side by Side Key Differences:

| Aspect | Modular Design | Integrated Design |

|---|---|---|

| Construction | Multiple modules combined | Single, solid pack integrated in frame |

| Scalability | High – easy to scale up or down | Low – fixed design |

| Weight and Space Efficiency | Moderate | High |

| Repair and Maintenance | Easier – swap individual modules | Harder – whole pack often replaced |

| Manufacturing Flexibility | Better for diverse models | Optimized for one platform |

In short, modular packs give you versatility and ease of maintenance, while integrated packs focus on maximizing performance and structural benefits. The choice depends largely on your EV’s design goals and platform needs.

Pros and Cons for EV Performance Energy Density and Range Optimization

When it comes to EV battery packs, energy density and driving range are top priorities. Here’s how modular and integrated designs stack up:

Modular Battery Packs Flexibility: Modular designs use smaller battery units put together, letting manufacturers easily adjust capacity for different models. This can help tailor range without redesigning the whole pack.Energy Density: Since modules include separate casings and connectors, there’s a bit more extra space and weight, which can slightly reduce overall pack energy density.

Range: Good for a balanced range, but not always optimized for maximum miles per charge because of packaging inefficiencies.Integrated Battery PacksHigher Energy Density: Integrated packs focus on a seamless cell-to-pack (CTP) structure, cutting unnecessary materials and weight. This means more battery cells fit into the same space, boosting energy per pound.

Longer Range: Cars with integrated packs can often deliver better driving range thanks to the compact design and better thermal management.

Packaging Efficiency: The lack of module boundaries allows for tighter configurations, which is great for maximizing usable volume.Bottom Line

If your goal is to squeeze the longest range and get the most energy per pound, integrated designs usually have the edge. But if you need flexibility to vary pack sizes and keep things scalable, modular battery packs offer more options.

Cost Manufacturing and Scalability Trade Offs

When it comes to cost, manufacturing, and scalability, modular and integrated battery pack designs each have clear strengths and challenges.

Modular battery packs typically offer lower upfront manufacturing costs because they use smaller, repeatable units assembled into a full pack. This means:

- Easier to scale production by adding standardized modules

- Faster prototyping and production cycles

- More flexible supply chains with scalable EV battery modules

- Lower tooling costs for OEM EV platform customization

However, the trade-off is some added complexity in pack assembly and wiring, which can slightly increase labor costs and potential points of failure.

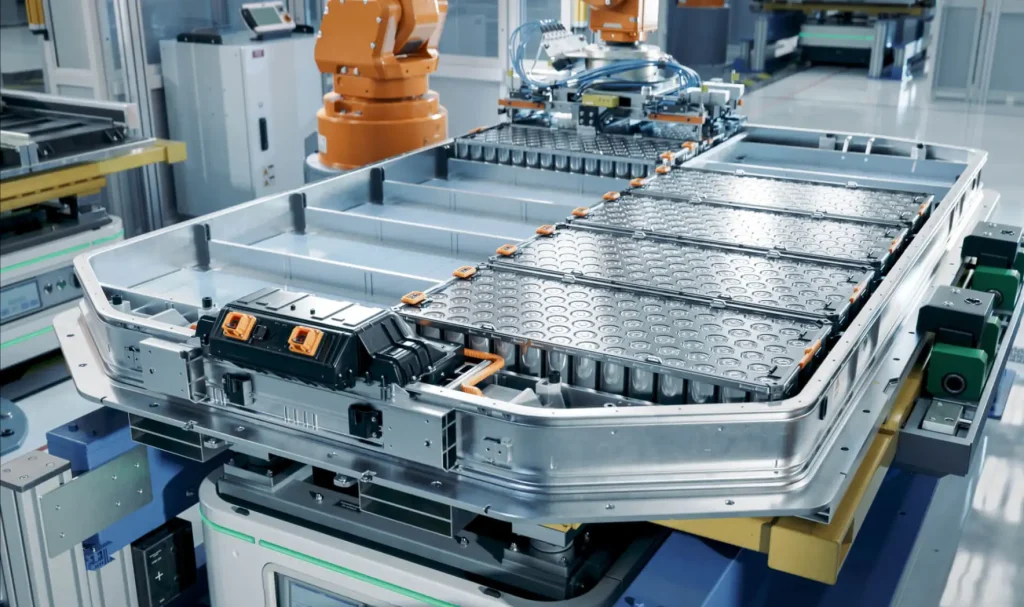

On the other hand, integrated battery pack designs often involve higher initial investments due to their custom-built, tightly packed structures. Investing in manufacturing these high voltage traction packs requires:

- Advanced automation and precise assembly lines

- Larger tooling and design setup costs

- Longer development time for cell to pack integration

But the benefit lies in superior space utilization, which can boost energy density and reduce overall pack volume. This design is often favored for high-performance EVs where minimizing size and weight is critical.

In terms of scalability:

- Modular designs adapt easily to different vehicle sizes and power needs by swapping modules.

- Integrated packs require redesigning the entire pack for each new model, slowing mass customization.

Bottom line: If your EV platform needs quick, cost-effective scalability and flexible manufacturing, modular packs are a strong choice. If maximizing range and pack compactness outweighs cost concerns, integrated packs might be worth the investment.

Balancing these trade-offs will help you align your EV production goals with battery design choices for the best ROI.

Pros and Cons for EV Performance Safety Thermal Management and Durability Factors

When it comes to safety, thermal management, and durability, modular and integrated battery pack designs each have unique strengths and weaknesses.

Modular Battery Pack Safety and Thermal Management

- Easier to isolate and replace individual modules in case of thermal runaway, reducing overall risk.

- Modular packs often use separate cooling loops for each module, which can simplify thermal management and prevent heat buildup.

- However, having more interfaces and connections between modules can increase failure points if not properly engineered.

- Durability is generally good, but vibration resistance depends on how well modules are secured within the pack.

Integrated Battery Pack Safety and Thermal Management

- Offers a more compact and rigid structure, often acting as a part of the vehicle’s chassis, which enhances crash safety.

- Integrated packs usually feature unified thermal management systems—such as liquid cooling plates—that create even heat distribution and reduce hotspots.

- Reduced number of connections and joints lowers risk of electrical faults and improves pack integrity.

- Built to endure harsh conditions, these packs often have better vibration resistance and longer lifecycle durability.

of Safety, Thermal, and Durability Factors

| Factor | Modular Battery Pack | Integrated Battery Pack |

|---|---|---|

| Thermal Management | Flexible, module-level cooling; may require more maintenance | Uniform cooling, better heat distribution |

| Safety | Easy isolation of faults; more connection points | Enhanced crash protection; fewer failure points |

| Durability | Good if well mounted; more mechanical interfaces | High structural integrity; robust for demanding use |

Ultimately, if your EV platform prioritizes ease of maintenance and quick repairs, modular packs can be safer to manage. But for applications demanding the highest structural strength, stable thermal control, and long-lasting durability—like commercial or heavy-duty EVs—integrated designs are often the better choice. Understanding these trade-offs helps tailor the EV battery design to your performance and safety needs.

Pros and Cons A Head to Head Comparison for EV Performance

Maintenance Recycling and Lifecycle Sustainability

When it comes to maintenance and sustainability, modular and integrated battery pack designs each bring different strengths to the table.

Modular Battery Packs

- Maintenance: Easier to service because individual modules can be swapped out without replacing the entire pack. This lowers repair costs and downtime for passenger EVs and fleets alike.

- Recycling: Modules simplify battery disassembly, making it easier to recycle cells and components efficiently. This supports better battery lifecycle recycling in line with U.S. sustainability goals.

- Lifecycle: The ability to replace worn or damaged modules means a potential longer overall battery lifespan, reducing waste and improving total cost of ownership.

Integrated Battery Packs

- Maintenance: More complex to repair since the pack is a single unit; issues may require full pack replacement, increasing cost and waste.

- Recycling: Integrated designs can be less straightforward to dismantle, slowing recycling processes and possibly affecting battery raw material recovery.

- Lifecycle: While integrated packs can be more durable structurally, any cell degradation typically impacts the whole pack, which can reduce overall life and increase replacement frequency.

If your priority is easier maintenance and sustainability, modular battery packs offer clear benefits—especially for OEMs focusing on scalable EV battery modules and sustainable EV battery design. Integrated packs, while robust, may involve higher lifecycle costs due to maintenance challenges and recycling complexity.

Choosing the right approach will depend on your platform’s needs, including how much emphasis you put on maintenance practicality and environmental impact in the U.S. market.

Best for Passenger EVs and Urban Mobility

When it comes to passenger electric vehicles and city driving, modular battery pack design often takes the lead. Modular packs offer flexibility, making it easier to customize battery size and capacity to fit smaller EV platforms used in urban settings. This benefits manufacturers aiming for efficient energy density without adding extra bulk.

Why modular fits urban mobility:

- Scalability: Modular packs can be scaled up or down, allowing automakers to adjust range and power easily.

- Cost-effective manufacturing: Building modular units simplifies assembly and speeds up production, helping keep prices competitive for city EV buyers.

- Easier thermal management: Smaller modules can be cooled more efficiently, reducing risks of EV battery thermal runaway and improving safety in stop-and-go traffic.

- Simpler maintenance: For daily commuters, modular designs mean quicker diagnostics and easier repairs or replacements.

While integrated battery packs provide a cleaner design and can sometimes offer better energy density, their rigid structure usually suits larger vehicles where space efficiency is critical. But for urban passenger vehicles focused on agility, convenience, and cost, modular battery pack designs often provide the best balance.

This approach suits OEM EV platform customization aiming to optimize battery lifecycle recycling and sustainable EV battery design tailored for city use. As a result, most passenger EVs rolling off U.S. assembly lines today lean on modular battery technology to meet everyday driving demands and environmental goals.

Ideal for Commercial Fleets and Heavy Duty Vehicles

When it comes to commercial fleets and heavy-duty vehicles, the battery pack design needs to prioritize durability, scalability, and ease of maintenance. Here, modular battery packs often take the lead due to their flexible and scalable nature.

Why modular fits commercial and heavy-duty use:

- Scalable EV battery modules: Modular packs allow fleet operators to scale up capacity easily as battery demand grows or shifts, which is key for trucks, buses, and delivery vans.

- Simpler maintenance and faster swaps: If a battery module fails, modular designs let you replace just that section—not the whole pack—cutting downtime significantly.

- Cost-effective manufacturing at scale: For fleets ordering in large numbers, modular packs lower production and repair costs while supporting OEM EV platform customization across multiple vehicle types.

- Robust thermal management: Heavy-duty vehicles generate lots of heat, and modular systems can be designed with effective EV battery thermal management to prevent thermal runaway and enhance safety.

- Enhanced durability: Modular packs handle the rough operating conditions of commercial use better, helping improve lifecycle sustainability and battery recycling processes.

That said, integrated battery packs can still find a place in some commercial vehicles, especially where weight reduction and high voltage traction packs are critical—for example, in aircraft or specialized EVs with tight packaging limits. But for most commercial fleets here in the U.S., modular battery pack designs deliver the balance of performance, cost, and serviceability needed for daily heavy-duty operation.

LEAPENERGY’s Expertise Tailored Solutions for Your Build

Choosing between modular and integrated battery pack designs can feel overwhelming, but it doesn’t have to be. At LEAPENERGY, we break down the decision process into clear steps to help you find the perfect fit for your EV platform. Here’s how we guide you:

| Step | Modular Battery Pack | Integrated Battery Pack |

|---|---|---|

| Vehicle Type | Flexible for multiple models | Ideal for dedicated platform |

| Energy Density | Moderate, easier to upgrade | Higher with structural integration |

| Cost | Lower initial cost, scalable | Higher upfront, efficient over time |

| Safety & Thermal | Good, depends on module design | Better cell-to-pack thermal control |

| Maintenance | Easier, plug-and-play modules | More complex but robust |

| Sustainability | Easier recycling and reuse | Durable but recycling can be complex |

1. Assess Your Vehicle’s Purpose and Usage

- Passenger cars often benefit from modular packs offering flexibility and easier upgrades.

- Commercial fleets or heavy-duty vehicles lean toward integrated designs for better energy density and durability.

2. Evaluate Performance Priorities

- Need higher energy density and longer range? Integrated packs pack more power in less space.

- Looking for simpler maintenance and scalable solutions? Modular packs allow easier swapping and repairs.

3. Consider Manufacturing and Cost Constraints

- Scalable EV battery modules suit platforms aiming for cost-effective production and volume flexibility.

- Integrated packs may require higher upfront tooling but can lower long-term costs through efficiency gains.

4. Factor in Safety and Thermal Management Needs

- LEAPENERGY applies advanced EV thermal management strategies to both architectures, ensuring safety and durability.

- We tailor cooling designs to prevent thermal runaway regardless of pack style.

5. Think About Sustainability and Lifecycle

- Modular designs offer easier battery recycling and replacement, aligning with sustainable EV battery design goals.

- We incorporate battery lifecycle recycling solutions to maximize environmental responsibility.

EXPLORE MORE LEAPENERGY MODULE BATTERY PACK

At LEAPENERGY, our custom approach combines deep knowledge of cell-to-pack integration and battery pack manufacturing best practices. We closely collaborate with OEMs to customize high voltage traction packs that suit your specific EV platform’s goals—whether it’s urban mobility or heavy-duty transport.

By working with us, you tap into proven expertise that helps you balance performance, cost, and sustainability with the right battery pack design for your needs. Contact LEAPENERGY to start building a tailored solution that drives your EV platform forward.