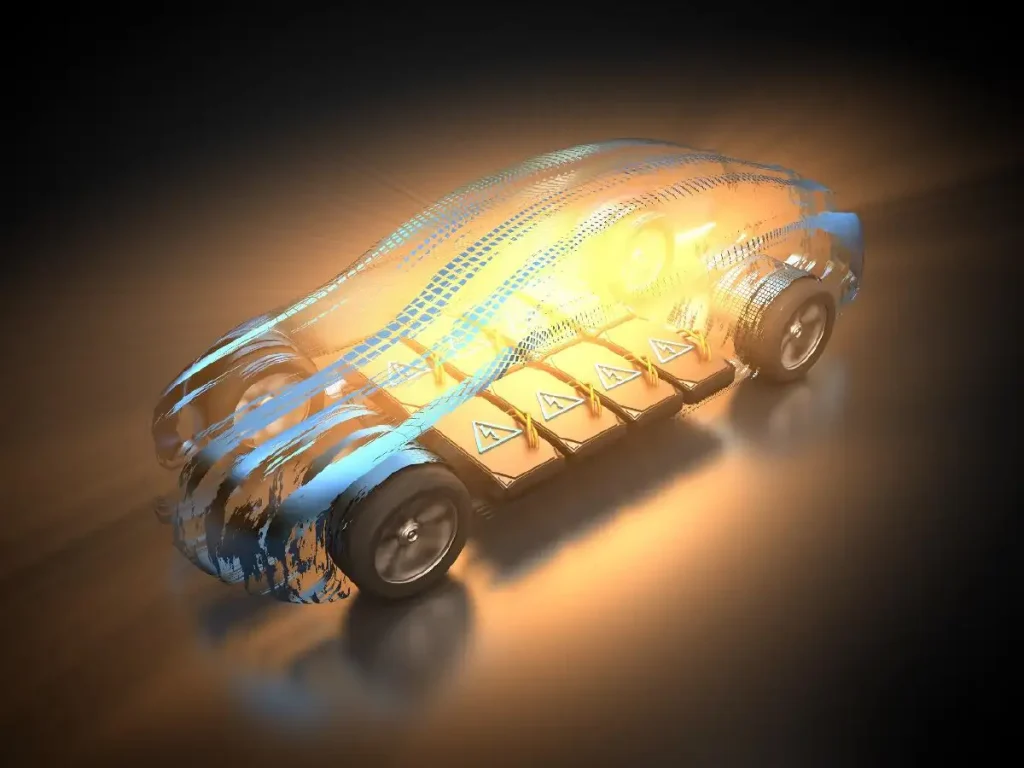

When it comes to EV battery thermal management, choosing the right cooling system can make or break your battery’s performance and lifespan. Whether it’s liquid cooling, air cooling, or a hybrid cooling system, each method plays a vital role in keeping high-voltage packs within optimal temperatures — especially under the intense demands of fast charging and extreme climates.

In this post, you’ll get a clear, side-by-side comparison to help engineering teams and OEMs optimize energy-efficient EV charging while reducing costs and complexity. Ready to see which cooling strategy powers your EV’s future? Let’s dive in.

Fundamentals of EV Battery Thermal Challenges

Managing heat in EV battery packs is critical for safety, longevity, and performance. Batteries generate heat primarily through two mechanisms:

- Joule Heating: Electrical resistance causes heat when current flows during charging and discharging.

- Electrochemical Reactions: Internal chemical processes produce additional heat, especially under high loads.

Ambient temperature also plays a big role. Hot weather can push batteries beyond safe temperatures, while cold can reduce performance and charging speed.

Optimal Operating Temperature: 20-40°C Range

Keeping battery cells within 20-40°C ensures:

- Safety: Minimizes risk of thermal runaway, a dangerous feedback loop causing overheating.

- Performance: Maintains capacity and charge acceptance.

- Longevity: Reduces degradation from heat stress.

Evolution of EV Powertrains: High Voltage and Fast Charging

Modern EVs increasingly use 800V architectures to enable ultra-fast charging. While this boosts charging speed, it generates more heat and energy loss during power transfer, increasing the thermal management demands on battery packs.

US Market Context: Adaptive Cooling for Real-World Driving

In the United States, cooling systems must accommodate:

- Diverse Driving Habits: From daily commutes to long highway trips, heat generation varies widely.

- Extreme Weather: Hot summers in the Southwest and bitter winters in the Northeast mean cooling systems need to adapt.

- Fast Charging Growth: With growing fast-charging stations, batteries face higher thermal loads, requiring advanced cooling strategies.

Understanding these fundamentals helps engineers design the right thermal management system for EV batteries — balancing safety, cost, and efficiency while meeting US market demands. LEAPENERGY stays ahead by supporting OEMs in integrating solutions built for this evolving landscape.

Air Cooling Systems for EV Battery Packs

Air cooling systems rely on moving air—either passively or actively—through ducts around the battery pack to remove heat. Passive airflow uses natural ventilation or driving motion, while active airflow employs fans and blowers to force air over cells. Ducting designs help guide air evenly, but uneven temperature distribution can still be a challenge.

Pros:

- Low upfront cost

- Lightweight and simple design

- Minimal maintenance needs

- Environmentally friendly (no liquids involved)

Cons:

- Limited heat dissipation capacity

- Uneven cooling can lead to hot spots

- Not ideal for fast charging, especially in high power EVs

A real-world example is the Nissan Leaf, which uses air cooling but has shown faster battery degradation in hot climates due to limited thermal management. For mostly low-power hybrid EVs, air cooling is still a practical choice, offering wiring cost benefits and easy system upgrades.

At LEAPENERGY, we see air-cooled battery packs as optimal for low-demand electric vehicles where cost and weight matter most. For users considering upgrades or higher performance needs, exploring hybrid or liquid cooling options can significantly improve battery life and efficiency. Explore our integrated EV battery solutions for tailored cooling strategies that balance cost and performance.

For deeper insights, check out our module-to-pack integrated EV battery systems page.

Liquid Cooling Systems

Liquid cooling relies on circulating a coolant—often a glycol-water mix—through indirect plates or even direct immersion in the battery cells. This system efficiently pulls heat away, keeping battery temperatures uniform across the pack. That uniformity is key for maintaining performance, especially with high-voltage 800V systems and fast charging demands common in U.S. markets.

Advantages:

- Superior heat removal compared to air cooling

- Keeps battery temperature stable and uniform

- Supports high-voltage architectures and aggressive fast charging

Drawbacks:

- More complex design and higher upfront costs

- Potential risk of coolant leaks requiring robust sealing

- Parasitic power draw from pumps and controls adds to energy use

Tesla’s Model 3 is a prime example of liquid cooling done right, allowing for sustained performance during long drives and fast charge sessions, even in various climates. LEAPENERGY studies highlight how OEMs integrate these systems to reduce wiring complexity inside EV battery packs, which can lower overall manufacturing costs and improve reliability. For those interested, the EV battery pack guide explained offers a detailed look at how liquid cooling fits into modern EV design trends.

Hybrid Cooling Systems for EV Batteries

Hybrid cooling combines the best of air and liquid cooling—using air-liquid combos, liquid integrated with phase change materials (PCMs), immersion hybrids, or systems that switch dynamically based on conditions. This approach tackles the thermal challenges of EV battery packs by delivering better temperature control and adapting to different driving scenarios.

Advantages include:

- Significant temperature reduction for improved battery health

- Weight savings compared to full liquid systems

- Better capacity retention during high-demand, fast-charging cycles

- Balanced efficiency that optimizes energy use without heavy parasitic losses

On the flip side, hybrid cooling is more complex to design and integrate. It demands higher R&D investment and can pose engineering challenges, but these are often outweighed by its modular nature, letting manufacturers tailor solutions for different EV models and climates.

In real-world terms, the Porsche Taycan stands out as a prime example of hybrid cooling in action—delivering exceptional battery temperature management to handle the high-output demands on U.S. roads and extreme conditions.

From LEAPENERGY’s perspective, hybrid systems are a smart move, especially with the focus on fast charging. They’ve shown up to a 20% efficiency gain in powertrain performance, helping EVs charge quicker and operate more reliably.

For deeper insights on keeping your EV battery pack in top shape with optimal cooling, check out LEAPENERGY’s detailed EV battery pack solutions.

Head-to-Head Comparison: Liquid Cooling, Air Cooling, and Hybrid Cooling for EV Battery Packs

When comparing air cooling, liquid cooling, and hybrid cooling for EV battery thermal management, several key factors stand out: performance, cost, safety, and how well each integrates with modern EV designs, especially 800V architectures common in fast-charging vehicles.

Performance Metrics

| Cooling Type | Heat Transfer Capacity | Temperature Uniformity | Fast-Charging Support |

|---|---|---|---|

| Air Cooling | Low | Uneven | Limited (slow heat removal) |

| Liquid Cooling | High | Very Uniform | Excellent (supports 800V+) |

| Hybrid Cooling | Moderate-High | Uniform | Very Good (balanced approach) |

- Liquid cooling shines in heat removal and maintaining even battery temps, critical under fast charge.

- Air cooling struggles with uniformity and limited heat dissipation, especially in hot climates.

- Hybrid systems offer a balance, improving uniformity with less weight than full liquid systems.

Cost and Efficiency

| Cooling Type | Initial Cost | Ownership Cost | Parasitic Power Draw |

|---|---|---|---|

| Air Cooling | Low | Low (minimal upkeep) | Very Low |

| Liquid Cooling | High | Moderate-High | Moderate (pumps, sensors) |

| Hybrid Cooling | Moderate-High | Moderate | Moderate-Low |

- Air cooling wins on upfront and maintenance costs.

- Liquid cooling’s complexity adds cost and parasitic energy use but boosts battery life.

- Hybrid cooling invests in design and R&D but gains efficiency through smart operation.

Safety and Durability

| Cooling Type | Thermal Runaway Prevention | Battery Life Impact | Temp Uniformity Benefits |

|---|---|---|---|

| Air Cooling | Limited | Faster degradation | Poor uniformity raises risk |

| Liquid Cooling | High | Extends life | Excellent thermal control |

| Hybrid Cooling | High | Maintains capacity | Balanced temp management |

- Liquid and hybrid cooling systems better prevent thermal runaway by managing hotspots.

- Air cooling may allow uneven heating, increasing safety risks over time.

Integration with EV Architectures

| Cooling Type | Suitability for 800V EVs | Wiring Complexity | OEM Scalability |

|---|---|---|---|

| Air Cooling | Limited | Simple wiring | Easy to scale |

| Liquid Cooling | Excellent, supports fast charge | Reduced wiring with plates | Preferred in premium EVs |

| Hybrid Cooling | Great, ideal for high output | Moderate complexity | Growing OEM adoption |

- Liquid and hybrid cooling fit well with modern 800V systems, reducing wiring complexity through integrated coolant channels.

- Air cooling remains standard for low-power, entry-level EVs but faces limits as fast charging demands grow.

For more details on how 800V EV battery platforms influence cooling choices, check out the insights on 800V EV battery pack platforms.

Choosing between these cooling types depends on your EV’s power needs, climate, and fast-charging frequency. Liquid and hybrid cooling are clear frontrunners for US drivers facing extreme weather and charging demands, while air cooling still holds ground in simplicity and cost.

Future Trends and Innovations in EV Battery Cooling

The future of EV battery thermal management is shaping up around smart and sustainable tech. AI-driven flow controls are emerging to precisely adjust cooling based on battery workload and ambient conditions, improving efficiency and extending battery life. Advanced phase change material (PCM) composites and refrigerant hybrid systems offer new ways to absorb and dissipate heat quickly, supporting ultra-fast charging without overheating.

Looking ahead, the biggest challenges include scaling ultra-fast charging without compromising safety or durability, especially in harsh climates common across the U.S.—think hot southern states or cold northern winters. Meeting these demands means innovations have to be robust, adaptable, and cost-effective.

LEAPENERGY is actively investing in hybrid cooling R&D to push the envelope on energy-efficient powertrain cooling solutions. This direction promises a balanced approach, maximizing capacity retention and extending battery pack life for American drivers with varying driving habits and charging needs.

To learn more about how evolving battery pack designs influence cooling strategies, check out our detailed global EV battery pack market outlook and insights on battery disconnect units enhancing EV safety.