The Foundation of EV Battery Safety: Core Risks and Regulatory Mandates

Electric vehicle (EV) battery safety starts with understanding the unique risks lithium-ion packs pose. Thermal runaway—a rapid, uncontrollable rise in temperature—remains the most critical hazard, potentially leading to fires or explosions. Other concerns include electrical short circuits, mechanical damage from impacts or vibrations, and chemical instability. These risks demand rigorous safety measures ingrained in every battery pack design.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) set strict standards to ensure consumer protection. Compliance with regulations like NHTSA EV battery standards and IEC 62660 for traction batteries is essential. These mandates focus on preventing thermal incidents, guaranteeing electrical integrity, and ensuring mechanical robustness under crash conditions.

For U.S. drivers, confidence in EV safety hinges on these foundational protocols. Integrating cutting-edge monitoring systems and meeting or exceeding regulatory benchmarks is not just a legal necessity—it’s the cornerstone of public trust and electric mobility’s future. At LEAPENERGY, we prioritize these core safety elements, building battery packs that reconcile regulatory demands with real-world reliability.

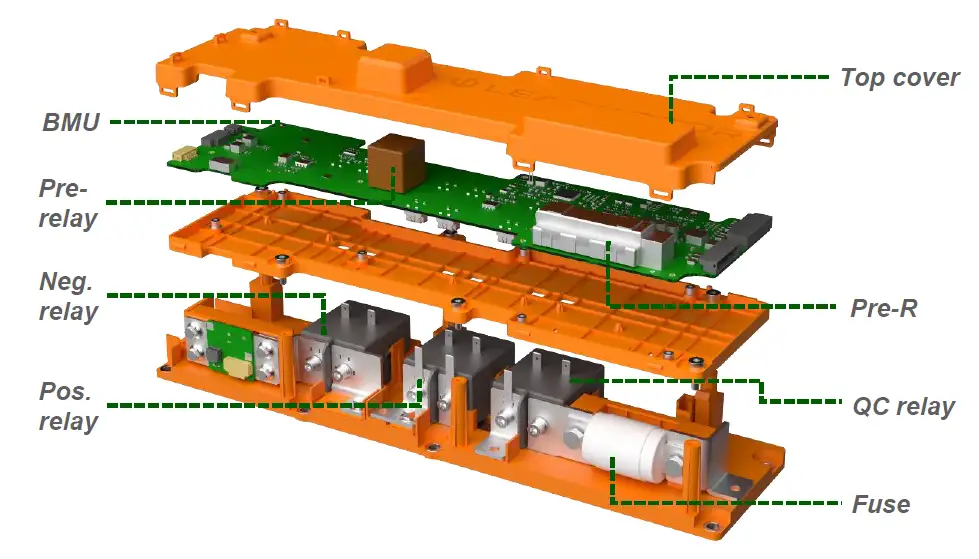

Battery Management System (BMS): Real-Time Monitoring and Integration

The Battery Management System (BMS) is the brain behind EV battery safety. It constantly monitors the battery’s status in real-time, making sure cells stay within safe voltage, temperature, and current limits. The system helps prevent issues like thermal runaway by managing charge and discharge cycles precisely.

Key BMS Features at a Glance:

| Feature | Purpose |

|---|---|

| Cell Voltage Monitoring | Prevents overcharge and deep discharge |

| Temperature Sensing | Detects overheating for thermal runaway prevention |

| State of Charge (SOC) Estimation | Optimizes battery usage and range control |

| Fault Detection & Isolation | Identifies faults and isolates affected cells |

| Communication Protocols | Links BMS with vehicle control units |

Besides safety, the BMS integrates closely with the EV’s high-voltage architecture—especially critical with modern 800V systems—to enable faster charging and reduced wiring complexity. This integration supports predictive analytics for battery health, enhancing long-term reliability.

Real-World Application:

Take LEAPENERGY’s modular BMS design, for example. It integrates multiple sub-features including lithium-ion pack isolation monitoring, which quickly flags any leakage currents, minimizing risks before they escalate. This smart integration follows industry standards including IEC 62660 compliance for traction packs.

For a deeper dive, check out the modular vs integrated EV battery pack guide that covers how the BMS fits into different EV designs.

A solid BMS is a must-have safety cornerstone that makes every EV battery pack smarter, safer, and more efficient in real-world driving conditions.

Thermal Management: Active vs. Passive Systems and Energy Efficiency

Thermal management is a critical safety feature in modern EV battery packs, directly impacting performance and longevity. There are two primary approaches: active and passive systems. Active thermal management uses coolant circulation, fans, or Peltier devices to maintain optimal battery temperature. These systems excel in fast-charging scenarios and extreme climates, preventing EV battery thermal runaway by keeping cells within safe limits. On the other hand, passive systems rely on materials like phase change substances or advanced insulation to absorb and dissipate heat without external power, offering a simpler and lighter solution.

Recent innovations blend both active and passive methods, using predictive analytics to adjust cooling proactively based on battery health and usage. This integration enhances energy efficiency, reducing battery cooling’s impact on overall range—crucial for meeting strict U.S. energy standards and rider expectations.

For EV owners in colder states, practical steps include:

- Preheating the battery pack before driving to improve efficiency

- Using scheduled charging during warmer times of the day

- Leveraging active thermal management capabilities when available

These strategies help maintain steady performance and extend battery life even in biting cold.

For a deeper insight into how advanced thermal solutions fit into broader battery pack designs, check out the detailed EV battery pack guide explained.

By managing heat well, today’s EVs stay safer, last longer, and deliver the kind of energy efficiency drivers want on every trip.

Electrical Protection in EV Battery Packs

Electrical protection is a must-have for any modern EV battery pack. It keeps the system safe from faults like short circuits, overcurrent, and electrical surges that can damage the battery or even cause a fire. High-voltage disconnects are key components—they quickly isolate the battery pack when problems arise, preventing further damage and ensuring passenger safety.

Key Electrical Protection Features:

| Feature | Purpose | Benefit |

|---|---|---|

| High-Voltage Disconnects | Automatically cut off current during faults | Prevents thermal runaway and fire |

| Fuses | Break circuit under excessive current | Protects wiring and cells |

| Short-Circuit Defense | Detects and interrupts dangerous arcs | Stops rapid battery failure |

| Overcurrent Protection | Limits current to safe levels | Avoids damage to battery and electronics |

| Advanced Sensors & BMS Integration | Monitors electrical health in real-time | Predictive analytics for battery health |

Modern EVs using 800V high-voltage battery protection systems benefit from faster charging and improved energy efficiency but also demand robust electrical safeguards to maintain compliance with regulations such as NHTSA EV battery standards. These standards ensure all components, including fuses and disconnect units, meet strict safety requirements.

For OEMs, adopting a high-voltage EV architecture not only cuts wiring costs but also supports advanced protective measures embedded into the battery design. This helps in reducing the risk of catastrophic failures while boosting overall system reliability.

If you want to dive deeper into how battery disconnect units enhance EV safety, check out this detailed guide on battery disconnect units. Also, comparing different voltage platforms like 400V vs 800V EV battery pack platforms can give you insight into electrical protection strategies tailored to your vehicle needs.

Electrical protection is the backbone of a safe EV battery pack, ensuring your ride stays reliable and secure during every drive.

Mechanical and Structural Integrity

Mechanical and structural integrity are critical safety features in modern EV battery packs. Crashworthy enclosures are designed to protect battery cells during collisions, preventing damage that could lead to thermal runaway or short circuits. These enclosures must meet rigorous standards, including vibration resistance and immersion resilience, to ensure the battery pack performs safely in diverse real-world conditions—from bumpy roads to water exposure.

LEAPENERGY leads innovation in this area, utilizing advanced materials and precision engineering to create robust battery housings that withstand impacts and harsh environments. Their battery packs undergo extensive crash testing and vibration assessments to validate performance, ensuring compliance with industry demands and giving U.S. drivers confidence in their EV’s durability and safety.

For more on how these innovations fit into wider EV safety and design trends, visit LEAPENERGY’s comprehensive insights on the global EV battery pack market outlook.

Fire Suppression and Emergency Response

When it comes to protecting modern EV battery packs, integrated fire suppression technology plays a crucial role in preventing thermal runaway from turning into a full-blown fire. Innovative systems, such as fast-acting chemical suppressants or directed venting, are now built directly into battery enclosures to quickly contain and cool any hotspots. This reduces damage and risk to passengers and first responders alike.

Post-event protocols are just as critical. Immediate isolation of the battery and controlled power-down help limit potential electrical hazards. Emergency response teams benefit from clear, standardized communication on battery status and risk through connected vehicle ecosystems. This integration ensures faster, safer interventions when incidents occur.

LEAPENERGY stands out with its advanced fire suppression solutions that combine rapid detection with smart response mechanisms. Their designs comply with strict NHTSA EV battery standards and deliver peace of mind for drivers across the U.S. market.

For a deeper look at how top EV pack manufacturers integrate these safety systems, check out this overview of top EV battery pack manufacturers in the U.S..

Key Highlights:

- Built-in chemical or aerosol fire suppressants

- Directed venting to safely release gases

- Automated battery isolation and power cut-off

- Real-time fire and thermal sensors linked to vehicle systems

- Coordination with emergency responders through vehicle telematics

Together, these fire suppression and emergency response features form a critical line of defense in making EVs safer for everyday use and rapid-charging scenarios.

Emerging Trends and Future-Proofing

The EV battery landscape is evolving fast, with new safety and sustainability breakthroughs shaping the future. One major trend is advanced materials that enhance battery longevity while reducing fire risks, such as solid-state electrolytes and safer chemistries like LFP (lithium iron phosphate). These options align with stricter regulations like NHTSA EV battery standards and IEC 62660 compliance, pushing the industry toward more resilient packs.

On the tech side, predictive analytics for battery health is gaining traction. Using AI and real-time data from integrated BMS, manufacturers can foresee failures before they happen, improving safety and extending pack life. Coupled with innovations in thermal management in EV powertrains, this helps prevent thermal runaway and adapts cooling strategies on the fly, especially in fast-charging EVs.

Sustainability is now front and center, too. LEAPENERGY is leading with eco-conscious designs focused on recyclability, reduced material waste, and energy-efficient manufacturing processes. Their vision includes future-proof battery packs that support higher voltage architectures, such as 800V systems, enabling faster charging and lower wiring costs—key benefits for the U.S. market.

Forward-looking tips to stay ahead:

- Embrace battery tech that balances safety with environmental impact.

- Prioritize packs with integrated fire suppression and electrical short-circuit defense.

- Opt for OEM battery strategies that future-proof your EV with scalable architectures.

- Keep an eye on new standards and certifications driving safer, more reliable packs.

For a deep dive into the benefits of safer battery chemistries, check out LEAPENERGY’s insights on why LFP batteries are best. Staying informed and choosing innovative, tested solutions ensures your EV’s safety and performance in the years ahead.