Understanding Standard EV Battery Packs

When I talk with OEM teams in the US, “standard” or off‑the‑shelf EV battery packs usually mean pre-engineered, modular systems that can be dropped into multiple vehicle platforms with minimal rework. These standard EV battery packs are built around fixed electrical specs, mechanical envelopes, and interfaces that an OEM EV program can adopt quickly without starting from a blank sheet.

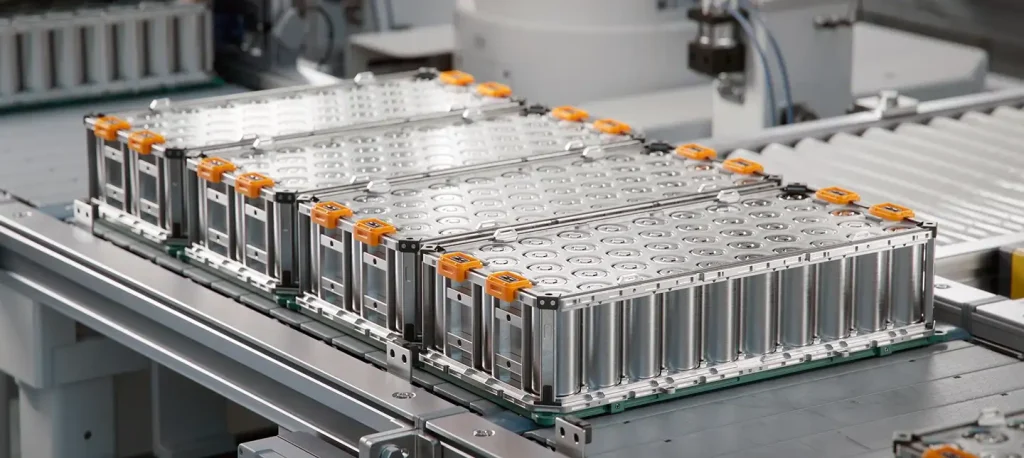

Most standard EV battery packs use one of three typical cell formats:

- Prismatic cells – Great for high packing efficiency and simpler module layouts; common in many mainstream EV battery pack OEM platforms.

- Cylindrical cells – Highly mature, easy to source at scale, and very robust; widely used where cost per kWh and reliability are critical.

- Pouch cells – Flexible shapes and good energy density, but require more careful mechanical and thermal design.

In a standard pack, the voltage, capacity, and module configuration are pre-defined. For example, you might see:

- Nominal pack voltages in the 350–400 V or 700–800 V range

- Capacity bands like 50–60 kWh, 70–80 kWh, or 90+ kWh

- Fixed module counts and series/parallel layouts that are consistent across a product line

These packs also follow standard form factors and packaging strategies that fit common EV skateboard platforms or underfloor installations:

- Flat, underbody packs designed for mass-market crossovers and sedans

- Modular “block” packs that can be combined for vans, light trucks, and fleet EVs

- Standardized mounting points, cooling interfaces, and high-voltage connectors

Because of this, standard EV battery packs fit cleanly into typical EV architectures: a central pack mounted in the floor, integrated with an existing BMS interface, DC fast-charging hardware, and standard high-voltage bus layouts. For many OEM EV battery pack programs, especially when speed and simplicity matter, this kind of pre-configured system is the most practical starting point.

Advantages of Standard EV Battery Packs for OEM Programs

Standard EV battery packs give OEMs in the U.S. a fast, low-risk way to launch or expand electric vehicle lines without blowing up budget or timelines.

Faster development and time-to-market

Off-the-shelf EV battery packs come with:

- Predefined voltages, capacities, and module layouts

- Existing test data and integration playbooks for common EV architectures

That means your engineering team spends more time integrating and less time inventing, which cuts months off the development cycle and helps you hit aggressive launch dates.

Lower engineering and NRE cost

With a standard pack, most of the hard work—mechanical design, BMS integration, and safety validation—is already done.

You avoid:

- Heavy NRE (non-recurring engineering) costs

- Multiple design spins and tooling changes

This keeps your EV battery pack cost per kWh and program budget under control, especially on lower-margin or fleet programs.

Easier validation, testing, and certification

Standard packs are usually:

- Pre-qualified to key EV battery pack certification requirements

- Validated for abuse tests, thermal runaway, vibration, and crash loads

You’re not starting from scratch with UL, UN38.3, or regional compliance, which speeds up sign-off and reduces certification risk for OEM EV battery pack programs.

Proven, field-tested reliability

Standard packs are often built on:

- Known cell chemistries and BMS platforms

- Designs already running in similar vehicles or fleets

That field history matters. It gives you real-world data on cycle life, failure modes, and thermal performance, minimizing surprises after SOP.

Easy to scale for high-volume production

These packs are designed for repeatable, high-volume builds:

- Mature assembly lines and automation

- Stable sourcing strategies and long-term supply contracts

If you’re planning high-volume EV battery pack production or wholesale programs, standard designs help you ramp up without straining your supply chain.

Lower integration risk for entry-level and fleet EVs

For city cars, last‑mile delivery, and basic fleet EVs, standard packs usually hit the sweet spot:

- Enough range and power for typical U.S. duty cycles

- Clean integration with common platforms and modular EV battery pack designs

If you don’t need extreme energy density or unique packaging, standard packs cut complexity and risk while keeping your TCO predictable. For a deeper dive on how pack layouts impact integration and risk, I’d look at this breakdown of modular vs. integrated EV battery pack designs.

Limitations of Standard EV Battery Packs

Standard EV battery packs are great for cost and speed, but they come with real trade-offs that OEMs in the U.S. market need to face head-on.

- Limited flexibility in size and mounting

Off-the-shelf EV battery packs lock you into fixed dimensions, layouts, and mounting points. If your chassis, wheelbase, or ground clearance is even slightly unique, you’ll likely be the one compromising the vehicle around the pack—not the other way around. - Compromises in energy density and range

Standard packs are designed to “fit most,” not to maximize every kWh. That usually means:- Lower pack-level energy density

- Shorter real-world range for the same footprint

- Less room to differentiate vs. other EVs using similar standard packs

- Thermal management that’s just “good enough”

Generic liquid or air-cooling designs can’t be tuned to your specific duty cycle, climate, or charge profile. In hot states like Arizona or high-load use cases like towing, that can mean:- Faster degradation

- Power derating under high load

- More conservative safety limits

- Hard to meet extreme or niche performance needs

High-performance, off-road, heavy-duty, or cold-climate EVs often push beyond what standard pack architectures can comfortably handle. You’ll hit limits on:- Peak power

- Fast-charging curves

- Cycle life under harsh use

- Weak product differentiation

When your EV shares the same standard battery pack as half the market, it’s tough to stand out on range, performance, or charging speed. You end up competing mostly on styling and price instead of core specs. - Suboptimal weight and space usage

Because standard packs aren’t tailored to your platform, you can see:- Non-ideal weight distribution (hurting handling and comfort)

- Wasted underbody or tunnel space

- Packaging workarounds that add cost and complexity

If you want a broader view of how pack design choices impact architecture, range, and performance, it’s worth looking at a more detailed EV battery pack guide covering pack types and layouts.

Understanding Custom EV Battery Packs for OEMs

Custom EV battery packs are built from the ground up around an automaker’s exact vehicle and program requirements, instead of using a generic, off‑the‑shelf pack. As an EV battery pack OEM supplier, I treat every custom project as a system-level design: we start from how you want the car to perform, then engineer the battery pack backward from there.

What Drives Custom EV Battery Pack Design

For OEM programs, custom EV battery packs are usually driven by one or more of these needs:

- Specific range and performance targets (0–60, towing, fast charge times)

- Unique vehicle layouts (skateboard platforms, pickup frames, vans, low-floor buses)

- Harsh duty cycles (fleets, logistics, ride-share, last-mile delivery, off-road)

- Regional safety and compliance requirements in the US and globally

Those OEM-specific requirements define everything about the custom pack design.

Key Design Levers in Custom Packs

When we design a custom EV battery pack vs standard, we tune a few main levers:

- Cell chemistry: NMC, LFP, or others depending on energy density, cost per kWh, safety, and cycle life

- Voltage and capacity: Pack voltage to match your inverter and drivetrain; kWh sized for your range target

- Pack architecture: Module-based, cell-to-pack, or cell-to-chassis for better energy density and platform scalability

This is where we unlock real EV battery pack performance optimization instead of accepting generic specs.

BMS, Software, and Communication

For OEM EV battery pack programs, the BMS integration is just as critical as the hardware:

- Custom BMS hardware sized to your pack layout and safety concept

- Software tuned for your thermal strategy, fast charging profile, and cycle life goals

- CAN, LIN, or Ethernet communication protocols matched to your vehicle ECU and existing architecture

A strong BMS design is what lets the pack safely deliver peak power, protect cells, and meet strict EV battery pack certification requirements.

Cooling and Mechanical Structure

Custom EV battery packs also let us tailor:

- Thermal management systems: Liquid cooling plates, cold plates, or refrigerant-based systems tuned to your real duty cycle and U.S. climate conditions

- Mechanical structures: Enclosures, mounting points, crash structures, and sealing (IP ratings) designed to your chassis and body-in-white

That’s how we hit both safety and durability targets without wasting space or weight.

From Requirements to Concept Design

Our typical custom EV battery pack engineering workflow for OEMs looks like this:

- Requirement capture: Range, power, charge time, duty cycle, packaging space, regulations, target EV battery pack cost per kWh

- Concept options: High-level pack architectures, chemistry options, voltage ranges, and thermal concepts

- Simulation and trade-offs: Model performance, safety, and thermal behavior to pick the best concept for your platform

If you want a broader view of how pack architecture and market direction are evolving before locking in a concept, it’s worth checking a global EV battery pack market outlook like this EV battery pack market overview for 2026–2030.

Custom EV Battery Pack Development Process

When we build a custom EV battery pack for OEM programs, we follow a tight, repeatable process that keeps risk low and performance high.

1. Early Feasibility & Requirements Alignment

We start with detailed feasibility work and requirement mapping with your engineering team:

- Define voltage, capacity, pack architecture, and duty cycle

- Lock in key targets: range, power, fast-charging, lifecycle, and cost per kWh

- Review safety, certification, and regional compliance requirements for the U.S. and global markets

This step makes sure the custom EV battery pack fits your platform and your budget before we cut any metal.

2. Pack Architecture Selection

Next, we select the battery pack architecture based on your vehicle platform:

- Choose cell format (prismatic, cylindrical, pouch) and chemistry

- Decide on module vs. cell-to-pack layout

- Align mounting, structural role, and crash requirements with your chassis team

The goal is a pack design that’s manufacturable, scalable, and easy to integrate for your OEM EV program.

3. Simulation and Modeling

Before prototyping, we run extensive digital analysis:

- Electrical performance and power delivery modeling

- Thermal management and cooling system simulations

- Safety, abuse, and fault-case modeling based on real-world U.S. duty cycles

We bake in EV battery thermal management and safety from day one, following best practices similar to those used by top global EV battery pack suppliers.

4. Prototyping, Bench Testing & Vehicle Validation

Once the virtual design is solid, we move to hardware:

- Build A-sample and B-sample prototype packs

- Run bench tests: performance, fast-charging, cycle life, and abuse tests

- Integrate into your mule vehicles for on-road validation

We tune BMS integration for OEM battery packs so communication, diagnostics, and safety logic work seamlessly with your vehicle controls.

5. Design Iteration with OEM Feedback

Based on test data and your team’s feedback, we refine:

- Mechanical design, harnessing, and mounting

- BMS algorithms, SOC/SOH accuracy, and safety thresholds

- Thermal system hardware and control strategies

This loop continues until the custom EV battery pack hits all OEM targets and certification requirements, including key EV battery pack safety features.

6. Industrialization and Ramp-Up

Finally, we industrialize for volume:

- Tooling design, fixture development, and line layout

- Process validation, PPAP, and quality control plans

- Scaled production for OEM EV battery pack programs with predictable lead times

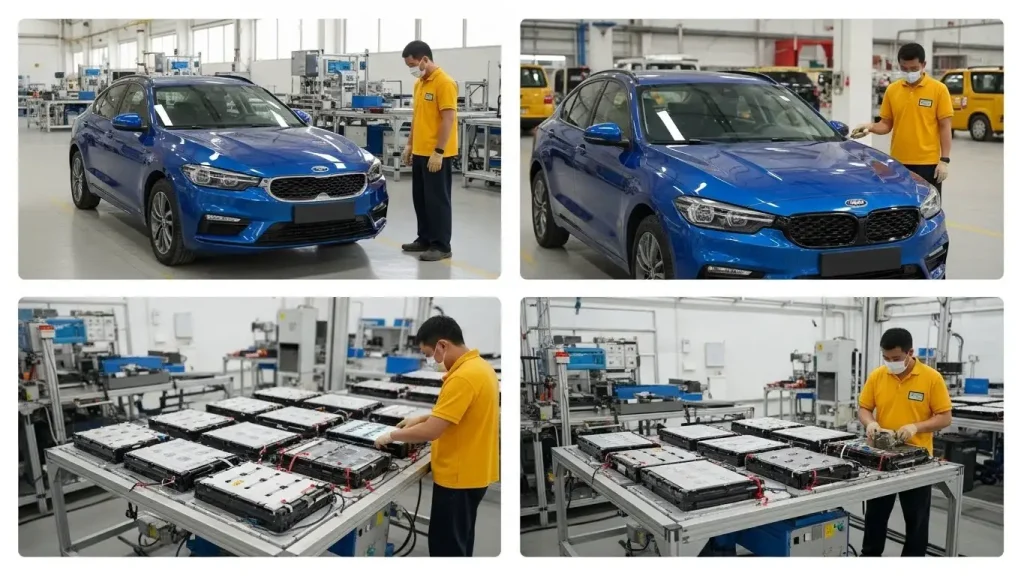

Our factories are set up for high-volume EV battery pack production and EV battery pack OEM supply, keeping cost per kWh competitive while maintaining tight quality standards for the U.S. market.

Advantages of Custom vs. Standard EV Battery Packs for OEM Programs

When I build custom EV battery packs for OEM programs, I’m focused on squeezing out performance, range, and lifetime value that off‑the‑shelf packs simply can’t match.

Optimized energy density and real-world range

With a custom EV battery pack, I can:

- Select the right cell chemistry and format to hit your exact energy density and range targets

- Tune pack architecture and cooling to reduce losses and improve pack-level efficiency

- Balance usable capacity vs. warranty life so your rated range matches real-world driving

This is how premium and long-range EVs get an edge over vehicles running standard, modular EV battery pack designs.

Higher power, fast charging, and longer cycle life

Custom packs also let me engineer:

- Higher discharge power for performance EVs, towing, or steep grades

- Stable fast-charging capability without overheating or excess degradation

- Cell, BMS, and cooling strategies that extend cycle life and reduce warranty risk

By designing the pack, BMS integration, and thermal system together, I can push faster charging safely while keeping EV battery pack cost per kWh optimized over the vehicle lifecycle.

Perfect fit and seamless integration

Instead of forcing your platform around a generic pack, I shape the pack around your vehicle:

- Custom enclosures to fit your chassis and body-in-white

- Mounting points aligned with your crash structures and NVH targets

- Cable routing, HV interfaces, and BDUs designed for clean integration

This reduces integration headaches and solves many OEM battery pack integration challenges up front.

Tailored thermal management and safety

Thermal and safety are where custom EV battery packs really stand out:

- Cooling plates, channels, and coolant loops built for your duty cycle and climate

- Protection strategies and battery disconnect units (BDUs) that enhance pack-level safety and crash response

- Market-specific safety and compliance engineered into the design from day one

If you’re digging into safety architecture, it’s worth understanding how BDUs enhance EV safety and fault protection in modern packs.

Stronger brand differentiation and specs

A custom EV battery pack lets you lock in:

- Unique range, charging, and performance specs your competitors can’t easily copy

- Software and BMS features that define your brand identity (charge profiles, power modes, thermal strategies)

- Platform scalability so you can spin multiple trims and variants from one optimized pack architecture

This is where custom vs. standard EV battery packs really separates mass-market from premium product.

Long-term cost and platform strategy

Yes, custom packs have higher NRE and engineering costs up front. But OEMs I work with usually gain that back through:

- Lower total cost of ownership via improved efficiency and durability

- Fewer compromises across future model years and platform refreshes

- Better alignment with long-term EV battery pack sourcing and regional production strategies

If you’re deciding between custom and standard packs for your next program, start by listing your must-have specs and constraints. A solid EV battery pack supplier that understands both custom and off-the-shelf solutions can help you model tradeoffs in NRE, lead time, and lifecycle cost.

Drawbacks and Risks of Custom EV Battery Packs

Custom EV battery packs can absolutely unlock top performance for OEM programs, but they come with real trade-offs you need to plan for.

Higher NRE and Engineering Cost

Custom EV battery pack engineering means higher NRE (non-recurring engineering) cost upfront. You’re paying for:

- Ground-up pack architecture design

- Custom BMS development and validation

- Tooling, fixtures, and unique production lines

For U.S. OEMs watching EV battery pack cost per kWh, this can be a big hit in the early phases, even if the long-term TCO looks good.

Longer Development and Validation

A custom pack adds months to your schedule:

- Detailed simulations, abuse testing, and regulatory compliance

- Multiple prototype loops and in-vehicle validation

- Extra time to dial in thermal management and software

That extended timeline directly impacts EV battery pack lead time and can push out your SOP date if not tightly managed.

More Technical and Project Risk

You’re dealing with higher complexity across:

- Cell selection, BMS integration, and pack controls

- Mechanical, thermal, and electrical interfaces to the vehicle

- Safety systems like BDUs, contactors, and fusing

This complexity demands strong program management and a capable EV battery pack manufacturer. Weakness in any area (design reviews, testing, documentation) turns into launch risk.

Dependence on the Right Supplier

With custom EV battery packs, you’re heavily tied to the expertise and quality systems of your automotive battery pack factory. If your supplier:

- Lacks deep BMS and thermal experience

- Struggles with automation or yield at scale

- Has gaps in functional safety or validation

You carry that risk into production. Vet their track record in high-volume EV battery pack production and critical subsystems like battery disconnect units (BDUs) early.

Supply Chain and Sourcing Challenges

Unique designs often mean:

- Non-standard cells or formats with longer lead times

- Custom cooling components, busbars, and enclosures

- Region-specific sourcing constraints for U.S. plants

That makes EV battery pack sourcing more fragile. Any disruption in one critical custom part can stall the entire EV program.

Scaling from Prototype to Volume

What works at prototype doesn’t always scale cleanly:

- Manual build techniques need to move to automated lines

- Tolerances, joining methods, and QA must be re-validated

- Process drift can affect safety and performance at volume

Scaling a custom EV battery pack from low-volume pilot to OEM-level mass production is a major step—if you don’t design for manufacturability from day one, you’ll feel it in delays and scrap.

Custom vs. Standard EV Battery Packs: Side-by-Side Comparison

When I build OEM programs, I always look at custom vs. standard EV battery packs through numbers, not hype. Here’s how they really stack up for automakers in the U.S.

Cost: Upfront vs. Total Cost of Ownership

- Standard packs

- Low upfront cost, minimal NRE (non-recurring engineering)

- Better for tight budgets and simple fleet EVs

- May cost more per mile over the vehicle life if range or efficiency is sub‑optimal

- Custom packs

- Higher NRE and engineering hours up front

- Can lower cost per kWh in mass production

- Better long-term TCO when volumes and platform life are high

Performance: Energy Density, Range, Power, Lifecycle

- Standard packs

- “Good enough” energy density and range for city and fleet EVs

- Power and fast-charging usually capped by generic cooling and BMS limits

- Lifecycle tuned for broad use, not extreme duty cycles

- Custom packs

- Pack architecture, cell choice, and 800V-capable designs can push range and power much higher (similar to how we approach high-voltage 800V EV batteries)

- Tailored cycle life for specific duty cycles (delivery, performance, towing)

- Easier to hit aggressive EPA range targets

Thermal Performance and Safety

- Standard packs

- Proven, conservative cooling concepts

- Safety features tuned to pass global norms, not specific regional or niche use cases

- Custom packs

- Vehicle-specific thermal paths, coolant routing, and cell-to-pack layout

- Can integrate advanced monitoring, fault isolation, and market-specific safety features

- Better control over thermal runaway mitigation and high C‑rate charging

Integration Effort and Packaging Complexity

- Standard packs

- Drop-in style integration, less CAD work and fewer validation loops

- May force compromises in ground clearance, trunk space, or seating layout

- Custom packs

- More engineering hours and cross-team coordination

- Perfect fit to chassis, underbody, and crash structures

- Cleaner wiring, easier service access, and better weight distribution

Scalability and Platform Flexibility

- Standard packs

- Work well for modular EV platforms that share the same footprint

- Limited flexibility when you add new body styles or long‑range variants

- Custom packs

- Designed for platform scalability (short‑range, long‑range, performance trims)

- Easier to reuse modules and sub-packs across multiple models and years

Time-to-Market Impact

- Standard packs

- Fastest way to launch an EV or fleet program

- Less risk in validation and certification, especially for new OEMs

- Custom packs

- Longer lead times due to design, simulation, and testing

- Pays off when your EV program needs standout specs and long platform life

Quick OEM Comparison Table

| Factor | Standard EV Battery Pack | Custom EV Battery Pack |

|---|---|---|

| Upfront cost / NRE | Low | High |

| Cost per kWh (high volume) | Medium | Low–Medium (depends on volume) |

| Energy density & range | Moderate | High, optimized |

| Power & fast charging | Limited by generic design | Tuned for high power / ultra-fast charging |

| Thermal management | Standard, proven | Vehicle-specific, optimized |

| Safety features | Generic global compliance | Tailored to region and use case |

| Integration effort | Low | High |

| Packaging / fit in vehicle | Fixed form factor | Custom fit to chassis and BIW |

| Scalability across models | Limited flexibility | High, good for platform families |

| Time-to-market | Short | Longer |

| Best for | Fleet, entry-level, fast launch | Premium, high-volume, or performance EV platforms |

If you’re planning a scalable EV platform or high-spec model, a custom EV battery pack—especially with advanced pack architectures like CTP/CTC (cell-to-pack and cell-to-chassis designs)—usually wins on performance and total cost of ownership. For budget-limited or fleet-focused programs, a proven standard pack often makes more business sense.

When Standard EV Battery Packs Make More Sense

Standard EV battery packs make a lot of sense when you’re trying to hit the market fast, control risk, and keep your EV program budget in check. As an OEM, you don’t always need a fully custom EV battery pack to win—sometimes an off‑the‑shelf or modular EV battery pack design is simply the smarter move.

Tight budgets and aggressive launch timelines

If you’re working with a strict budget and a hard launch date, standard EV battery packs are usually the better fit:

- Lower NRE and engineering cost – You avoid the heavy custom battery pack engineering and validation spend.

- Shorter EV battery pack lead time – You can move from sourcing to SOP faster because the pack is already designed and certified.

- Less program risk – Most of the technical issues have already been worked out on previous OEM EV battery pack programs.

For many U.S. startups and mid-sized automakers looking to prove out a business model first, a standard EV battery pack keeps the financial exposure under control while still delivering reliable performance.

Fleet vehicles, last‑mile delivery, and city EVs

Standard packs are especially strong for fleet EVs, commercial vans, and last‑mile delivery vehicles:

- Daily, predictable duty cycles

- Lower range expectations

- High focus on total cost of ownership and uptime

In these cases, an off‑the‑shelf EV battery pack with proven reliability is often more valuable than squeezing out a few extra miles of range. Fleets care more about:

- Low cost per kWh

- Fast serviceability

- Easy replacement from stable, high‑volume EV battery pack manufacturers

When energy density and styling aren’t top priorities

If your vehicle doesn’t live or die on range bragging rights or ultra-sleek packaging, a standard pack is usually enough:

- Entry‑level and mid‑market EVs

- Shared mobility, car‑share, or rental fleets

- Utility and work vehicles

You accept a “good enough” energy density to keep price and complexity down. Instead of paying for a custom high‑performance EV battery pack design, you lean on a standard module‑based pack that’s already optimized for cost and reliability.

Platforms using standardized battery modules

If your platform is designed to use existing standardized modules, a standard EV battery pack gives you:

- Fast integration with minimal re-engineering

- A clear path to platform scalability across trims and variants

- Easier sourcing and EV battery pack wholesale options from multiple factories

This approach is common when OEMs want to share a battery architecture across several models or regions while still managing EV battery pack cost per kWh.

Limited certification risk and engineering resources

When your internal engineering team is small or already stretched, standard packs reduce the load:

- Pre‑tested, pre‑certified designs minimize EV battery pack certification work.

- You lean on the EV battery pack supplier’s quality systems and compliance experience.

- Less internal bandwidth is required for BMS integration, thermal modeling, and safety case development.

In these situations, working with an experienced automotive battery pack manufacturer that offers standard pack platforms lets you stay focused on the vehicle, not reinventing the battery. If you want to go deeper into how pack design impacts safety, performance, and project risk, I often recommend reviewing technical insights similar to what you’d see in specialized battery and energy storage resources before locking in your sourcing strategy.

When Custom EV Battery Packs Are the Better Choice

Custom EV Battery Packs for Premium and Performance EVs

If you’re building a high‑performance or premium EV in the U.S. market, custom EV battery packs are almost always the smarter move. You get:

- Higher energy density for longer real-world range

- Stronger power delivery for instant torque and consistent performance

- Tuned BMS integration for fast charging and track or towing modes

That’s how you hit standout specs that actually show up in marketing, EPA range labels, and independent road tests.

Unconventional Layouts and Tight Packaging

For vehicles with tricky layouts—pickup trucks, vans, low-floor shuttles, off-road rigs—a standard EV battery pack usually forces compromises. With a custom battery pack you can:

- Shape the pack to your chassis and body-in-white

- Use space around crossmembers, tunnels, and floor steps

- Dial in weight distribution for better handling and safety

This is especially key for U.S. OEM EV platforms that share frames with ICE or hybrid models.

Harsh Duty Cycles and Tough Environments

If your program targets work trucks, delivery fleets, off-road vehicles, or high-mileage ride-hail use, a custom EV battery pack lets you:

- Design thermal management for hot U.S. states and fast-turn fleet charging

- Reinforce enclosures for vibration, dust, water, and road salt

- Optimize chemistry and pack architecture for long cycle life under abuse

This is where off‑the‑shelf EV battery packs often struggle to meet real fleet uptime and TCO expectations.

Brand Differentiation and Long-Term Strategy

OEMs chasing strong brand identity around range, performance, and fast charging need custom packs to stand out in a crowded market:

- Unique specs that aren’t shared with competitors using the same standard modules

- Pack and BMS tuned to your driving modes, UX, and charging profile

- Better alignment with long-term platform roadmaps and mid-cycle refreshes

Custom EV battery packs also make it easier to stretch one vehicle platform across multiple trims, from base to performance, without redesigning the whole vehicle.

Ultra-Fast Charging and Next-Gen Features

If you’re targeting ultra-fast charging (250 kW+), advanced thermal control, or future V2G / V2H capability, you need the custom route:

- Cell selection and pack layout optimized for high C‑rate charging

- Cooling systems designed for repeated DC fast charge use

- BMS and communication protocols built around your specific charging strategy

As an EV battery pack manufacturer and OEM-focused supplier, I use custom EV battery packs to help U.S. automakers and fleet builders hit aggressive specs that standard packs simply can’t reach—while keeping an eye on pack cost per kWh, lead time, and scalable production from prototype to high-volume.

Choosing and Working with an EV Battery Pack Manufacturer

When you’re building an OEM EV program in the U.S., your EV battery pack supplier is as critical as your motor or chassis partner. I always tell OEM teams: pick your EV battery pack manufacturer like you’d pick a long‑term tech partner, not a commodity vendor.

What OEMs Should Look For in an EV Battery Pack Supplier

Focus on a battery partner that can handle both off‑the‑shelf EV battery packs and fully custom EV battery packs for OEMs.

Core checkpoints:

- Proven OEM EV battery pack projects (reference programs, SOP history)

- Ability to quote EV battery pack cost per kWh clearly and transparently

- Experience with EV battery pack wholesale and long-term supply contracts

- U.S.-friendly support: time zone, language, and local application engineering

Experience in Custom vs. Standard EV Battery Packs

You want a manufacturer that can support custom EV battery packs vs standard in the same factory. That gives you flexibility across entry-level and premium platforms.

Why this matters:

- Standard packs: fast launch, lower NRE cost, less engineering overhead

- Custom packs: higher performance, better packaging, stronger brand differentiation

- Mixed strategy: standard pack for fleet models, custom pack for flagship or performance trims

Technical Capabilities That Actually Matter

Your automotive battery pack manufacturer should be strong in real engineering, not just assembly.

Key capabilities:

- Cell selection: prismatic, cylindrical, pouch; LFP vs NMC; sourcing at scale

- BMS integration: CAN, LIN, Ethernet; software, diagnostics, safety functions

- EV battery thermal management system: liquid cooling, cold-weather performance, fast-charging thermal control

- Mechanical design: pack housing, crash structures, sealing (IP rating), mounting to body-in-white

| Area | What I Look For |

|---|---|

| Cells & Chemistry | Multiple Tier-1 cell suppliers, chemistry guidance by use case |

| BMS & Software | In-house BMS design, OTA-ready, ISO 26262 know-how |

| Thermal Design | Proven liquid cooling, validated in hot & cold U.S. climates |

| Mechanical & Safety | Crash-tested designs, UL/UN/IEC experience |

Manufacturing Capacity, Automation, and Quality

For U.S. OEM programs, high-volume EV battery pack production and consistent quality are non-negotiable.

Ask direct questions:

- Annual EV pack capacity (MWh/GWh) and spare capacity for your ramp

- Automation level (welding, dispensing, end-of-line test)

- Quality systems: IATF 16949, ISO 9001, PPAP, traceability down to cell level

- Ability to support EV battery pack OEM builds plus pilot runs and custom battery pack prototyping

Support for OEM Programs and After-Sales

A good EV battery pack manufacturer behaves like an engineering partner, not just a factory.

Look for:

- Joint engineering teams for co-development

- On-site support during prototype builds and first installations

- Help with EV battery pack certification requirements (FMVSS, UN 38.3, UL, regional rules)

- After-sales: diagnostics support, warranty data analysis, service part strategies

How Partnership Models Impact Cost, Lead Time, and Scale

How you structure the partnership will decide your EV battery pack lead time, cost, and scalability.

Common models:

- Off-the-shelf / standard pack:

- Pros: quickest lead time, lowest NRE, cleanest launch

- Best for: fleet EVs, last-mile, lower range city EVs

- Customized standard (modular EV battery pack design):

- Pros: moderate NRE, some packaging/firmware tweaks, faster than full custom

- Best for: platform sharing, multiple trims, regional variants

- Full custom pack:

- Pros: maximum performance, packaging fit, and differentiation

- Cons: higher NRE, more validation, more supplier dependency

Always align:

- Upfront vs. lifecycle cost: look at EV battery pack total cost of ownership, not just piece price

- Supply chain & sourcing strategy: China-based automotive battery pack factory, U.S./Mexico assembly, or hybrid model

- Future scalability: can the same pack architecture scale across multiple EV models and facelifts?

Choosing the right EV battery pack supplier upfront will save you months in launch time and millions in redesigns later.