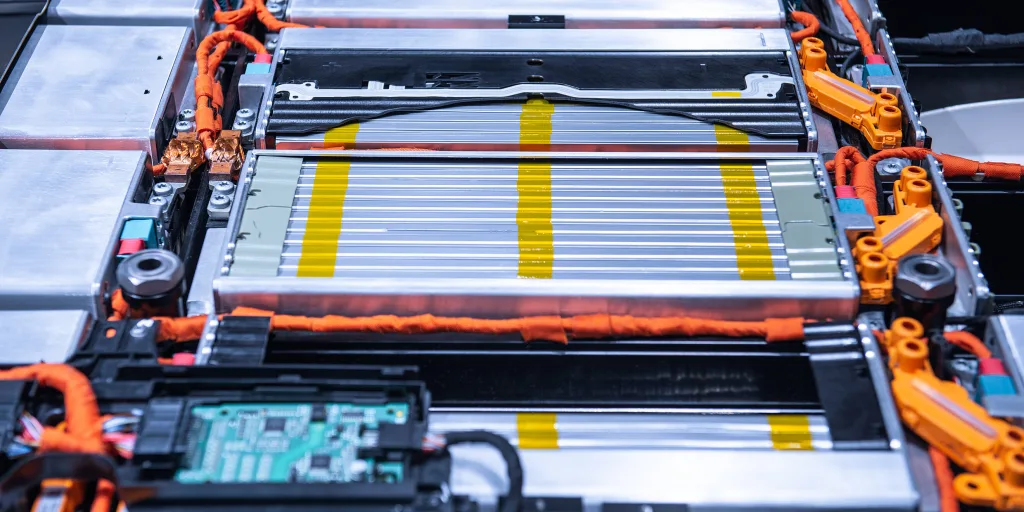

The Battery Pack: From Component to Structural DNA

The EV battery pack has evolved far beyond just being a power source — it’s now the structural backbone of electric vehicles. As the industry shifts from traditional 400V to advanced 800V architectures, battery packs have become a critical bottleneck. Older designs simply can’t keep up with the demands of higher voltage systems, faster charging, and greater energy density.

Enter two game-changing innovations: Cell-to-Pack (CTP) and Cell-to-Chassis (CTC) technologies. Since the prismatic cell revolutionized battery design decades ago, these two advances represent the biggest leaps in how batteries are integrated structurally.

- CTP technology eliminates the module layer, simplifying the pack and boosting energy density.

- CTC technology takes it even further by integrating battery cells directly into the vehicle’s load-bearing chassis.

LEAPENERGY stands at the forefront of this evolution. From being an early CTP adopter to pioneering full CTC integration, LEAPENERGY leads the way in redefining battery pack design for the next generation of 800V EV platforms. This structural innovation is not just about saving space or weight — it sets the DNA for future EV performance, safety, and cost efficiency.

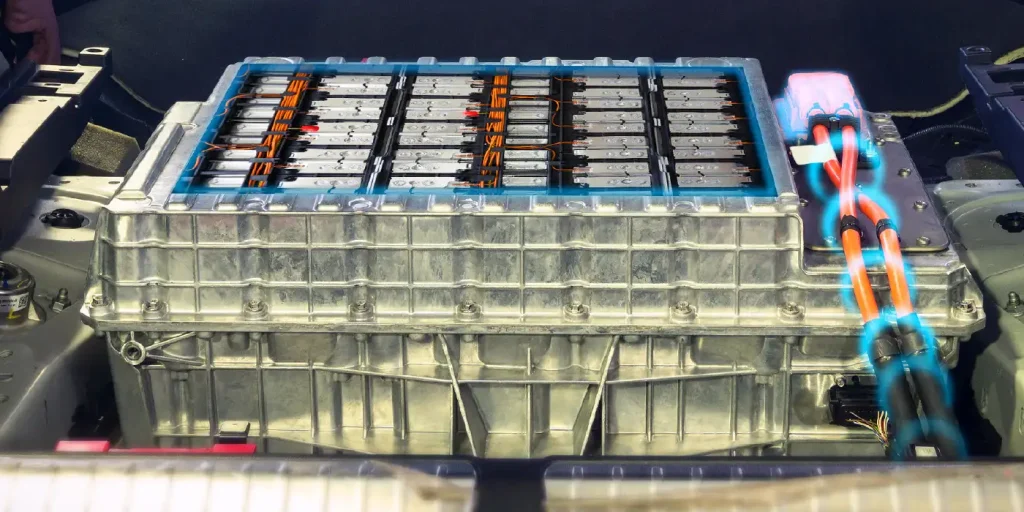

Understanding the Evolution: CTP vs. CTP+ vs. CTC

Let’s break down the three key stages shaping LEAPENERGY’s battery innovation:

- CTP (Cell-to-Pack) removes the traditional module layer, connecting cells directly into the pack. This cuts down on unnecessary parts, improving energy density and simplifying assembly.

- CTP+ is LEAPENERGY’s own upgrade to CTP. It adds smarter thermal management and better structural design, making batteries safer and more durable while keeping the pack compact.

- CTC (Cell-to-Chassis/Body) takes it a step further by integrating the battery directly into the vehicle’s load-bearing structure. This means the battery isn’t just a power source — it becomes part of the car’s frame, improving stiffness, safety, and reducing overall weight.

This evolution from CTP to CTC marks a powerful shift toward highly efficient, structural battery packs that deliver better performance and real-world benefits. For more insight on the difference between modular and integrated designs, LEAPENERGY offers a detailed look at modular vs. integrated EV battery pack.

Core Performance Gains Delivered by LEAPENERGY’s CTP Technology

LEAPENERGY’s Cell-to-Pack (CTP) technology brings real, measurable improvements that matter for EV drivers and manufacturers alike:

- Volumetric efficiency: By removing the traditional module layer, CTP boosts pack energy density by 15–25%, packing more power into the same space.

- Gravimetric efficiency: This streamlined design also cuts battery pack weight by 10–15%, helping vehicles go farther with less mass.

- Cost reduction: Fewer parts mean 40% fewer components, which simplifies assembly and lowers manufacturing costs—good news for OEMs looking to reduce EV powertrain cost.

- Thermal management: Direct cell cooling leads to a more consistent temperature, reducing thermal gaps (ΔT), which extends cycle life and allows for safer, faster charging.

These gains position LEAPENERGY’s CTP packs as a smarter, more efficient choice for high-voltage EV architecture, especially when paired with an 800V electric vehicle system. For a deeper dive into how this fits into today’s trend toward module-less battery design, check out our detailed EV Battery Pack Guide Explained.

Taking It Further: LEAPENERGY’s CTC Structural Battery Revolution

LEAPENERGY pushes battery innovation beyond Cell-to-Pack by integrating cells directly into the vehicle’s Body-in-White (BIW) through Cell-to-Chassis (CTC) technology. This means the battery isn’t just packed inside the car—it becomes part of the car’s very frame. By embedding the battery pack into the structural chassis, LEAPENERGY significantly boosts the vehicle’s torsional rigidity by 40%, improving overall stiffness and crash performance.

This structural integration also allows for a lower floor height, which results in more interior space for passengers and cargo – a key advantage for U.S. drivers focused on comfort and usability. Compared to traditional CTP designs, LEAPENERGY’s CTC delivers an additional 8–12% weight reduction at the system level, contributing to better range and efficiency.

This evolutionary leap aligns perfectly with the high-voltage EV architectures driving fast charging and range improvements today. For more on how LEAPENERGY is shaping battery pack platforms, check out the detailed breakdown of 400V vs 800V EV battery pack platforms.

Real-World Impact on Key EV Metrics

LEAPENERGY’s innovations with 800V architecture combined with their CTC battery technology bring game-changing benefits to EV performance. Fast charging is significantly boosted — drivers can go from 10% to 80% state of charge in under 12 minutes thanks to improved thermal management and higher voltage systems. This means less downtime and more time on the road.

Range also gets a solid boost, with 12–18% more usable energy packed into the battery. This increase in volumetric and gravimetric efficiency translates straight to longer trips without increasing battery size or weight.

For automakers, these advancements lower total ownership costs. The optimized battery pack design reduces material and production expenses, while faster charging and improved durability enhance vehicle value over time. LEAPENERGY’s solutions align well with the evolving needs of US OEMs looking for scalable, cost-efficient, and high-performance EV battery packs.

For more on top industry players innovating in this space, check out the top 9 EV battery pack manufacturers in the US.

Safety Redefined: Structural Integration Meets Advanced Protection

LEAPENERGY’s Cell-to-Chassis (CTC) design takes battery safety to a new level by making the battery pack part of the vehicle’s skeleton. This integration dramatically improves side pole and bottom impact resistance, boosting crash performance without adding extra weight. Thanks to our proprietary adhesive and laser welding processes, the pack achieves superior structural integrity, minimizing risks caused by vibration or mechanical stress.

Another key safety advantage comes from the module-less architecture, which helps prevent thermal runaway from spreading across cells. This design innovation cuts down the chances of fire propagation, ensuring enhanced protection for both the vehicle and passengers. For EV makers aiming for cutting-edge safety paired with structural efficiency, LEAPENERGY’s approach sets a new industry standard.

Explore how these advancements fit into our broader battery solutions at LEAPENERGY’s product page.

Manufacturing & Scalability Advantages for OEM Partners

LEAPENERGY’s structural battery innovations don’t just boost performance—they simplify manufacturing too. By cutting down the number of components and eliminating complex module assemblies, gigafactory production lines can be streamlined by over 30%. This reduction in capital expenditure (capex) means OEMs face lower upfront costs and simpler factory setups.

What’s more, LEAPENERGY offers turnkey CTP and CTC solutions that accelerate time-to-market, helping electric vehicle makers stay competitive in the fast-evolving 800V EV platform landscape. These ready-to-deploy systems integrate smoothly with existing production workflows.

Plus, LEAPENERGY’s battery packs are compatible with a range of chemistries, including LFP, NCM, and next-generation semi-solid batteries—giving OEMs flexibility to tailor battery choices based on performance, cost, and safety preferences.

For a deeper dive into how battery design impacts long-term reliability, check out our insights on what kills your EV battery faster.

LEAPENERGY’s Roadmap: From CTP 2.0 to Full CTC 3.0 (2026–2028)

LEAPENERGY is gearing up for big leaps between 2026 and 2028, moving from CTP 2.0 to a full CTC 3.0 battery solution. This next phase promises 25–30% more pack energy density, pushing the limits of what high energy density battery packs can do for EV performance and range.

On top of the density boost, LEAPENERGY’s next-gen CTC will enable ultra-fast charging speeds, getting from 5% to 80% state of charge in just 8 minutes. This breakthrough, paired with the 800V EV platform, means less downtime and more time on the road—exactly what U.S. drivers want.

In short, contact LEAPENERGY to know how structural battery packs deliver efficiency, safety, and fast charging—cutting total ownership costs while improving reliability across all EV models.