Unique Requirements for Commercial EV Battery Packs

When it comes to electric commercial vehicle batteries, they’re not just bigger versions of passenger EV batteries. The demands on heavy-duty EV battery packs are on a whole different level, shaped by their tougher duty cycles and operational needs.

How Commercial Packs Differ from Passenger EV Batteries

| Feature | Passenger EV Batteries | Commercial EV Batteries |

|---|---|---|

| Capacity | Moderate (50-100 kWh) | High (150 kWh+) |

| Cycle Life | Lower due to lighter use | Extended cycle life for daily heavy use |

| Vibration Resistance | Standard road conditions | High vibration from rough terrain |

| Thermal Management | Basic cooling systems | Advanced cooling to handle long hours and heavy loads |

Commercial vehicles operate under much harsher conditions — frequent stops, heavy loads, and longer duty cycles demand batteries designed to endure stress without compromising battery degradation or performance.

Duty Cycles Shape Battery Design

Battery packs tailor their specs to fit distinct commercial uses:

- Urban Delivery: Frequent stops, start/stop cycles, and regenerative braking allow moderate range but require robust thermal control to handle constant charging variations.

- Long-Haul Trucking: High energy density is critical for long distances; weight balance is key to maximize payload without sacrificing range.

Balancing Energy Density, Weight & Payload

For fleet operators, every pound matters:

- Higher energy density increases range without adding bulk.

- Lightweight battery packs preserve payload capacity, directly impacting operational efficiency.

- Custom packaging helps fit batteries within chassis limits while ensuring thermal management and durability.

In short, commercial EV battery packs demand a precision-focused design balancing capacity, durability, and weight — a challenge that passenger EV packs simply don’t face. This foundational difference makes choosing the right battery pack pivotal for optimized fleet performance and cost-effectiveness.

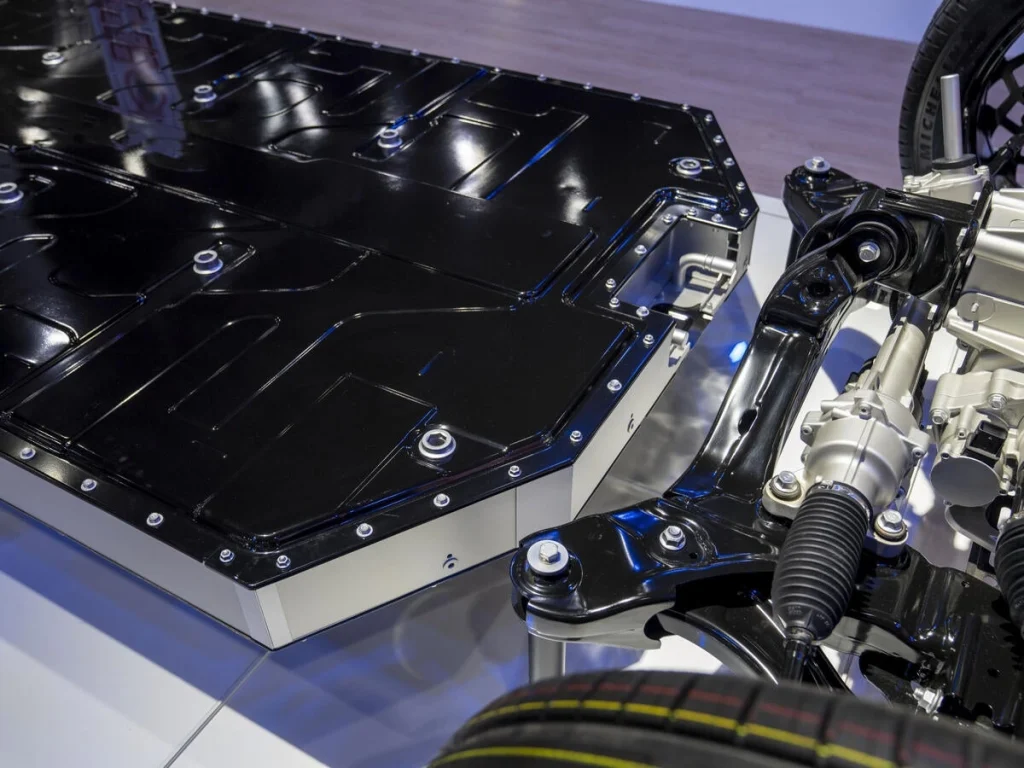

Key Technologies in Modern Battery Pack Design

Modern electric commercial vehicle battery packs rely on advanced technologies to meet demanding performance and durability needs. One major innovation is Cell-to-Pack (CTP) technology, which integrates cells directly into the pack without extra modules. This boosts energy density, reduces weight, and streamlines manufacturing—crucial for heavy-duty EV battery packs aiming to maximize payload and efficiency. Taking it a step further, Cell-to-Chassis (CTC) integration embeds the battery directly into the vehicle structure, improving overall vehicle rigidity and freeing up space, an important advantage for urban delivery vans and buses.

When it comes to architecture, choosing between modular and integrated battery systems affects scalability and serviceability. Modular setups offer easier maintenance and upgrades, while fully integrated packs optimize size and weight for long-haul trucks. Both approaches benefit from the use of high-quality lithium-ion cells that deliver reliability and longer cycle life. To keep these cells performing safely under heavy use, battery packs incorporate advanced cooling systems—including liquid cooling and phase-change materials—to manage thermal loads efficiently, preventing degradation and enhancing fast charging capabilities.

For more details on pack integration and modular design benefits, visit our guide on modular vs integrated EV battery pack systems and explore the latest in module-to-pack integrated EV battery systems.

Safety and Compliance Standards for Commercial EV Battery Packs

Safety is non-negotiable when it comes to electric commercial vehicle batteries. Meeting and exceeding key certifications like UN 38.3, IEC 62660, ISO 6469, and UL 2580 is essential, especially for heavy-duty EV battery packs that face tougher operating conditions. These standards cover everything from safe transport and handling to electrical safety and environmental resilience.

Commercial battery packs also undergo rigorous thermal runaway prevention tests, mechanical abuse simulations, and fire propagation mitigation to ensure reliability in real-world scenarios. LEAPENERGY goes beyond these global standards, integrating advanced safety features such as robust battery disconnect units and multi-layer thermal management to safeguard against hazards during operation and charging. This commitment to safety supports healthier fleets and enhances overall vehicle uptime. You can learn more about LEAPENERGY’s safety focus and certifications at their detailed page on UL 2580 and ISO 26262 EV battery certifications.

By combining compliance with innovative safety engineering, LEAPENERGY’s commercial EV battery packs meet the highest demands of the US heavy-duty market while ensuring long-term durability and peace of mind.

Performance Optimization Strategies for Commercial EV Battery Packs

Optimizing battery performance for electric commercial vehicles means focusing on long cycle life and minimal degradation. Monitoring the state of health (SOH) consistently helps maintain battery reliability over thousands of miles. This tracking ensures batteries stay balanced and healthy, extending their usable life and reducing unexpected downtime.

Fast charging is a must for fleet vehicles. Modern battery packs support high-power fast charging without compromising lifespan, letting trucks and delivery vans spend more time on the road instead of waiting to recharge. This boosts productivity while protecting the battery’s long-term health.

Improving range and energy efficiency is critical. Lightweight, optimized battery pack packaging reduces vehicle weight, which directly improves range and payload capacity. Using innovative materials and smart layouts helps balance energy density, weight, and space, all essential for commercial EVs that need to go farther and carry more.

At the core of these strategies are advanced Battery Management Systems (BMS). These systems handle precise cell balancing, run real-time diagnostics, and use predictive maintenance to spot issues before they impact performance. A reliable BMS ensures consistent battery output and maximizes safety.

To dive deeper into how battery pack design impacts performance and efficiency, check out our detailed guide on ev battery pack integration and explore the latest innovations in 800V battery pack platforms.

LEAPENERGY’s Innovative Battery Pack Solutions

LEAPENERGY delivers custom high-capacity battery packs designed specifically for medium- and heavy-duty electric commercial vehicles. Their solutions focus on pushing the boundaries of energy density, supporting ultra-long cycle life, and enabling rapid charging without sacrificing battery health. This makes them ideal for tough commercial use cases, including delivery fleets, transit buses, and heavy construction equipment.

Their advanced battery technologies help fleets achieve greater uptime and range while reducing operational costs. Thanks to optimized packaging and lightweight design, these battery packs maximize payload capacity—a crucial factor for commercial vehicles in the U.S. market.

Sustainability is another core focus, as LEAPENERGY develops durable battery systems that lower total cost of ownership (TCO) and minimize environmental impact by extending battery life and facilitating easier recycling. For more on how LEAPENERGY stands out in the competitive landscape, their insights on EV battery pack trends across China, the USA, and Japan offer valuable context for commercial EV adoption globally.

Future Trends in Commercial EV Battery Packs

The future of electric commercial vehicle batteries is evolving fast, with higher integration technologies like Cell-to-Pack (CTP) and Cell-to-Chassis (CTC) leading the way. These approaches reduce weight and complexity while boosting energy density, making battery packs more efficient and reliable. You can explore how CTP and CTC innovations elevate EV battery performance in detail here.

Solid-state batteries are another exciting trend. Offering greater safety, faster charging, and improved energy density, solid-state tech could revolutionize heavy-duty EV battery packs. Alongside this, ultra-fast charging solutions are becoming more common to support commercial fleets that demand quick turnaround times without sacrificing battery life.

Sustainability also plays a big role in future battery solutions. Second-life battery applications, where used EV batteries get repurposed for less demanding energy storage, help reduce waste and costs. Meanwhile, recyclability innovations are improving, enabling a circular economy approach for commercial EV batteries.

All these advancements are fueling faster adoption of electric vehicles in heavy-duty sectors like delivery fleets, buses, and construction vehicles—pushing the industry toward greener, more efficient transport in the U.S. market and beyond.