Phase 1: Validating Technical Capability & Design Robustness

Engineering Verification and Validation (V&V)

First, I ask: Does the supplier follow a structured V-Model for V&V?

This ensures stage-by-stage testing aligns with design requirements. I focus on whether the prototype hits these critical technical targets:

- Thermal management: Can the system maintain safe operating temperatures?

- Energy density: Does it meet the expected capacity per volume or weight?

- Structural integrity: Is the pack mechanically sound and robust under stress?

Meeting these theoretical limits confirms engineering precision and design maturity at the prototype stage.

Hidden System Risks & Failure Paths

Cell-level performance is just one piece. I’m concerned about system-level failure modes that might not be obvious initially. Key questions include:

- How does the Battery Management System (BMS) respond to secondary failures like cooling pump stoppage?

- Are failure paths mapped beyond simple cell faults, such as thermal runaway propagation or wiring faults?

Proactive Failure Mode and Effects Analysis (FMEA) at the system level is vital here to uncover risks that could escalate post-production.

Design for Manufacturing (DFM) Readiness

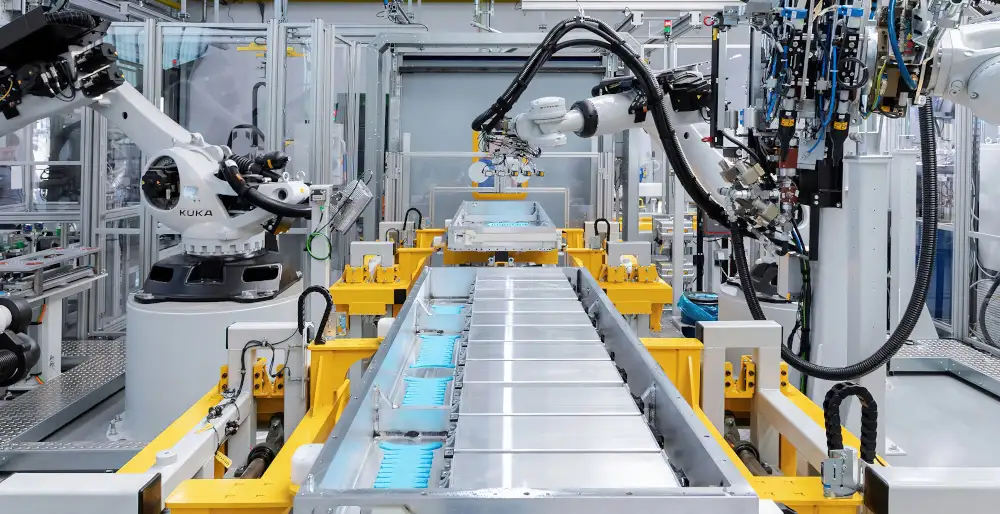

A prototype built by hand often won’t translate well to production. I evaluate:

- Is the design optimized for mass production techniques (e.g., automated welding over manual soldering)?

- Are there clear features aimed at process consistency and quality control?

- Do manufacturing methods support repeatability and scalability?

Early DFM assessment predicts if the supplier can deliver reliable volumes without costly redesigns.

| Focus Area | Key Questions | What I Look For |

|---|---|---|

| Engineering V&V | Does the prototype meet design goals? | Thermal management, energy density, structure |

| System-level Risk Assessment | Are hidden failure paths identified? | BMS response, thermal runaway, system FMEA |

| Design for Manufacturing (DFM) | Is mass production readiness evident? | Automated processes, consistent assembly methods |

This first phase lays the groundwork to trust the supplier’s technical capability and design robustness before moving forward.

Phase 2: Stress Testing & Reliability Assessment

During the prototype stage, stress testing is essential to evaluate the battery system’s true limits. The “destruction” test pushes the prototype until failure, revealing whether the battery responds in a controlled manner or suffers catastrophic thermal events. This failure mode analysis is crucial—it tells you if potential risks like thermal runaway are manageable or dangerous.

Reviewing Accelerated Life Testing (ALT) protocols helps verify long-term stability and environmental resilience. You want transparent ALT data showing how the battery performs under extreme conditions such as vibration, temperature shocks, and high humidity. This ensures reliability not just today, but throughout the product’s lifecycle.

Software plays a vital role here, too. Checking the Battery Management System (BMS) validation during the prototype phase means assessing its capability to fine-tune algorithms in real time. A flexible and robust BMS improves safety and efficiency, adapting to real-world stresses before production.

For deeper insights on ensuring battery reliability through testing, check out our guide on assessing long-term reliability of Chinese battery system suppliers. Ensuring early verification of stress responses keeps your project on the right track toward durable, safe battery systems.

Phase 3: Process Control & Engineering Maturity

Evaluating a battery system supplier in the prototype stage means digging deep into their process control and engineering maturity. Here’s what to focus on:

Requirements Traceability

- Confirm every feature in the prototype maps back to the original Requirement Specification Document (PRD).

- Look for gaps where the prototype might miss critical requirements.

- This step ensures alignment with your project goals and avoids surprises later on.

Documentation Completeness

- Check if test reports, material certifications, and assembly logs are thorough and well-organized.

- Quality documentation at this stage signals a supplier who understands the importance of traceability and quality control.

- Red flag: Messy or incomplete documentation often foreshadows trouble during mass production.

Root Cause Analysis Capability

- Assess how the supplier handles issues: Do they use structured methods like 5 Whys or the 8D methodology instead of quick patches?

- Strong root cause analysis (RCA) means problems will be solved properly, reducing risks of repeated failures.

| Key Aspect | What to Check | Why It Matters |

|---|---|---|

| Requirements Traceability | Link prototype features to PRD | Ensures full requirement coverage |

| Documentation Completeness | Quality of test reports & logs | Signals process discipline and quality control |

| Root Cause Analysis | Use of 5 Whys / 8D methods | Enables deep, long-lasting fixes |

This phase is critical to anticipating production challenges early. A supplier with mature engineering controls sets you up for smoother New Product Introduction (NPI) and better long-term reliability.

For further insights on managing early technical risks, check our detailed guide on five hidden risks in battery pack procurement beyond technical specifications.

Phase 4: Communication & Change Management (The “Soft” Hard Skills)

Effective communication and change management are critical during the prototype validation process. One key element is design change control, particularly how the supplier handles Engineering Change Orders (ECOs) during the iteration stage. You want to see quick, accurate implementation of design changes without introducing new issues or breaking other system functions. This ensures that improvements happen smoothly while maintaining overall system stability.

Equally important is the cross-functional engineering review. Direct access to thermal, mechanical, and electrical engineers—rather than filtered communication through sales teams—is essential. This direct engineer-to-engineer collaboration speeds up troubleshooting, allowing prompt identification and resolution of issues. When suppliers promote open, technical dialogue, it’s a strong sign they understand the complex interactions within the battery system and can respond swiftly to challenges.

Strong communication combined with robust change management supports a streamlined New Product Introduction (NPI) process and helps mitigate hidden system risks early on, setting the stage for reliable mass production. For further insights into managing supplier complexities during prototype stages, see our resource on common OEM mistakes with EV battery packs.

Why LEAPENERGY Sets the Standard for Prototype Evaluation

LEAPENERGY leads the way in battery system supplier evaluation and prototype validation by applying a rigorous internal engineering verification and validation (V&V) protocol that goes beyond typical client requirements. Their thorough testing covers everything from thermal management and battery pack structural integrity to accelerated life testing (ALT) protocols, ensuring the prototype reliably meets design robustness and system-level failure mode analysis.

What sets LEAPENERGY apart is their collaborative approach—they treat every project as a partnership, not just a supply deal. This mindset helps reduce risks early on by identifying hidden system risks and refining the battery management system (BMS) logic during the prototype stage. Their focus on cross-functional engineering review and real-time design change control keeps development efficient and transparent.

Additionally, LEAPENERGY commits to full data transparency, sharing detailed test results and failure mode insights openly. This open communication builds trust and supports informed decision-making throughout the New Product Introduction (NPI) process. Learn more about their advanced standards in 800V EV batteries and how their approach drives safety and quality. This commitment ensures clients get a reliable, manufacturable battery system ready to handle US market demands with confidence.