Phase 1: Engineering Competence & Design Maturity

Assessing the long-term reliability of Chinese battery system suppliers starts with a deep dive into their engineering competence and the maturity of their design processes. In the competitive landscape of OEM battery manufacturing China, the ability to deliver robust, scalable designs is non-negotiable.

Design for Manufacturability (DFM)

A critical early indicator is the supplier’s approach to Design for Manufacturability (DFM). Effective DFM analysis reduces complexity, optimizes the BOM, and ensures the design aligns with their production capabilities. Key points to evaluate:

- Does the supplier integrate DFM early to avoid costly redesigns?

- How well do they balance innovation with production efficiency?

- What tools or standards do they use to verify design feasibility at scale?

A mature DFM process signals lower risks of manufacturing bottlenecks and product recalls down the line.

Validation & Testing Protocols

Next, look closely at their battery system validation protocols. Rigorous testing—covering performance, safety, and environmental stress—is essential to guaranteeing product longevity. Pay attention to:

- The scope and depth of factory acceptance testing (FAT) and site acceptance testing (SAT).

- Use of industry-recognized standards and custom test cycles mimicking real-world conditions.

- Documentation quality and repeatability of test results.

Comprehensive validation helps uncover design flaws before full-scale production, reducing warranty costs and customer dissatisfaction.

Engineering Change Management (ECM)

Finally, robust Engineering Change Management (ECM) is crucial for managing design revisions without causing disruptions. Evaluate their ECM processes for:

- Structured change request and approval workflows.

- Clear communication channels across engineering, manufacturing, and quality teams.

- Traceability of changes to maintain version control and compliance.

Effective ECM minimizes risks related to late-stage modifications and aligns project lifecycle management with production timelines.

In , strong engineering expertise combined with mature DFM, reliable validation protocols, and disciplined ECM forms the foundation of trustworthy battery system sourcing. Suppliers excelling in this phase are better positioned to offer consistent quality and innovation, reflective of industry benchmarks like LEAPENERGY’s standards for battery system procurement and battery pack supplier evaluation.

Phase 2: Supply Chain Stability & Scalability

When assessing long-term reliability of Chinese battery system suppliers, supply chain stability is a top priority. A solid upstream sourcing strategy means suppliers rely on reputable Tier 1 battery cell sourcing partners, minimizing risks tied to raw material shortages or quality issues. This foundation is critical to avoid disruptions that impact your production timeline and delivery commitments.

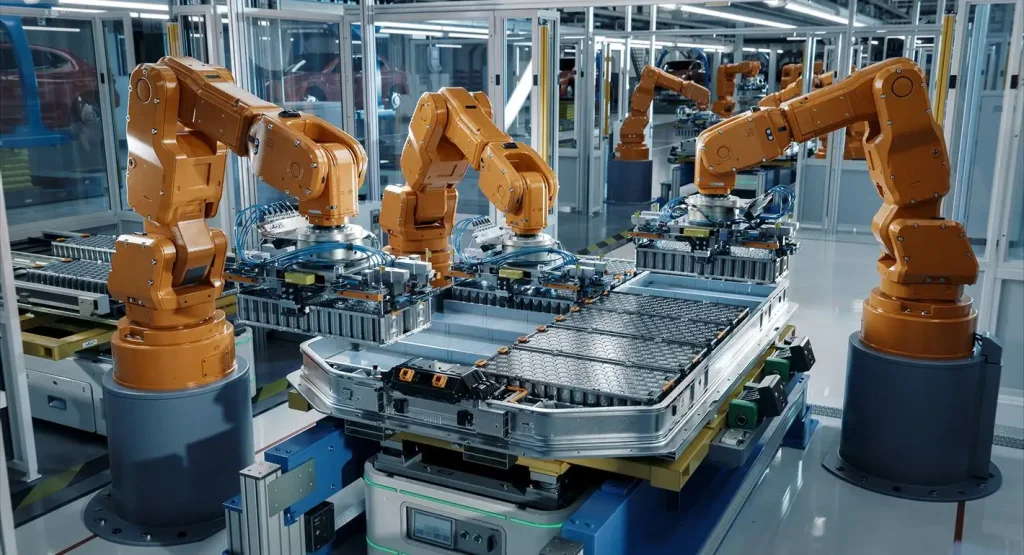

Manufacturing capacity and scalability are equally important. Suppliers must demonstrate they can ramp production smoothly without sacrificing quality. This includes flexible facilities and robust processes designed for scalable energy storage production. Planning for future volume increases upfront helps prevent bottlenecks and delays when demand surges.

Cross-functional engineering coordination is another key factor. Effective collaboration across procurement, design, and manufacturing teams ensures smooth transitions and quick issue resolution during scaling. This reduces project delivery risk and supports efficient execution of custom battery pack projects. For more insights on managing growth and supplier evaluation, consider how OEM battery system partnerships handle these challenges in practice, as detailed in our guide on how OEMs evaluate EV battery pack suppliers.

Key points to evaluate:

- Stability of sourcing critical components from trusted suppliers

- Capacity to scale manufacturing without losing delivery capability

- Cross-team coordination supporting agile changes and integration

- Risk mitigation in overseas procurement strategies

Focusing on these areas helps secure a resilient supply chain and sets the stage for long-term battery system sourcing success aligned with the U.S. market’s demand for reliability and supply continuity.

Phase 3: Quality Management Systems (QMS) & Compliance

When assessing the long-term reliability of Chinese battery system suppliers, a strong Quality Management System (QMS) is essential. Look closely at how they balance process control throughout manufacturing versus relying mainly on final inspection. A solid QMS ensures consistent quality by preventing defects during production rather than catching them later, which reduces risks in battery system procurement.

Compliance and certification readiness are critical too. Suppliers should be proactively prepared for international standards like ISO 9001 battery supplier certification, UN38.3, and IEC 62660, which align with global OEM requirements. This readiness not only confirms quality but also smoothens product integration and regulatory approvals. For a deeper dive into certification essentials for battery packs, reviewing resources like our detailed EV battery pack certification guide can be very useful.

Key focus areas include:

- Audit results from their Battery Quality Management System (QMS)

- Documented process controls versus outcomes of final product inspections

- Traceability and accountability of parts, especially from Tier 1 battery cell sourcing

- Up-to-date compliance with relevant energy storage certifications to avoid supply disruptions

Strong QMS and compliance management in Chinese battery system manufacturers reduce long-term project delivery risks and protect against unexpected production issues, ensuring you get reliable, consistent battery packs every time.

Phase 4: The Financial Reality: TCO vs. Sticker Price

When assessing Chinese battery system suppliers, it’s easy to get caught up in the sticker price. But the real story lies in the battery system total cost of ownership (TCO). Beyond the upfront cost, hidden engineering costs often surface—like design tweaks, rework due to manufacturability issues, and ongoing quality fixes. These hidden expenses can quickly outpace initial savings.

Performing a thorough lifecycle cost analysis is critical. This means looking at costs over the entire project lifespan, including procurement, integration, maintenance, and technical support. Understanding these factors helps avoid surprises and ensures your battery pack supplier evaluation goes beyond just price tags.

Keeping an eye on lifecycle cost analysis energy storage not only helps in budgeting but also highlights risks related to project lifecycle management. Businesses sourcing OEM battery manufacturing in China need this holistic view to mitigate long-term project cost risk.

For example, investing in design for manufacturability (DFM) early can reduce hidden engineering costs down the line. You can also explore how battery pack integration cuts manufacturing cost and supports a lower total cost of ownership, giving you a clearer financial outlook on your supplier partnership.

Phase 5: Post-Deployment & Long-Term Partnership

When assessing the long-term reliability of Chinese battery system suppliers, the post-deployment phase is crucial. A strong technical support structure ensures any issues after installation are handled quickly, minimizing downtime and protecting your investment. Look for suppliers offering clear long-term technical support agreements that cover troubleshooting, software updates, and spare parts availability.

Equally important is the cultural fit and communication between your team and the supplier’s. Smooth communication helps avoid misunderstandings, align expectations, and speed up problem resolution. This is especially relevant for complex projects like custom battery pack integration where precise coordination across teams is essential.

| Key Post-Deployment Factors | Why They Matter |

|---|---|

| Long-term technical support | Fast resolution, extended system life |

| Clear communication channels | Avoids project delays, improves collaboration |

| Understanding cultural differences | Builds trust and smoother negotiations |

Prioritize suppliers with proven experience in ongoing support and a reputation for strong cross-cultural cooperation. This reduces risks in battery system procurement and supports a productive OEM battery system partnership.

For more on designing reliable battery packs that simplify long-term service, check out the insights on designing durable automotive-grade battery packs for long-term reliability.

Also, review common challenges in overseas sourcing that could impact post-deployment support by visiting our guide on OEM EV battery packs common mistakes.