Core Components and Their Individual Roles

In electric vehicle (EV) battery systems, the Battery Disconnect Unit (BDU) and Battery Management System (BMS), or Battery Management Unit (BMU), serve distinct yet complementary functions essential for safety and performance.

Battery Disconnect Unit (BDU) Overview

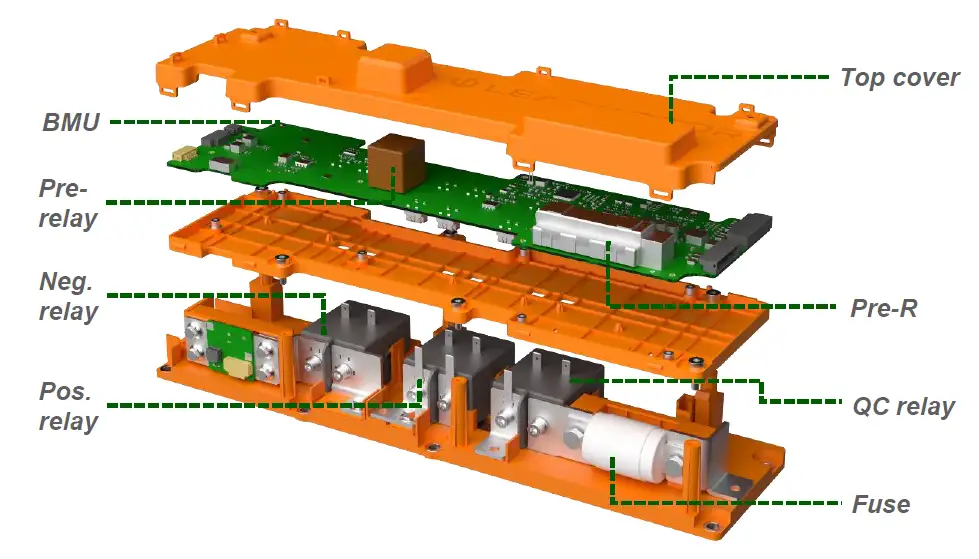

The BDU acts as the high-voltage gateway of the battery pack. It physically controls the electrical connection between the battery and the vehicle’s powertrain through key components, including:

- High-voltage contactors: Enable safe connection and rapid disconnection of the battery pack

- Fuses: Provide overcurrent protection by interrupting fault currents

- Pre-charge circuits: Prevent inrush current surges during power-up

- Arc suppression mechanisms: Reduce electrical arcs during contactor switching for enhanced safety

This hardware-centric role ensures immediate isolation from hazardous electrical conditions, serving as the final physical barrier to protect the vehicle and battery.

Battery Management System (BMS/BMU) Overview

The BMS or BMU serves as the intelligent monitoring and control layer. Its core responsibilities include:

- Cell-level monitoring: Measures voltage, current, and temperature of individual cells within the battery pack

- State of Charge (SOC) and State of Health (SOH) estimation: Evaluates battery capacity and remaining usage life

- Protection logic enforcement: Triggers safety actions such as disconnection commands or fault alerts based on defined thresholds

The BMS provides continuous diagnostic insights and makes calculated decisions to optimize battery usage and prevent damage.

Key Differences and Complementarities

- The BDU physically disconnects and protects the electrical system by controlling high-voltage contactors and safety devices

- The BMS delivers intelligent decision-making by analyzing battery conditions, predicting faults, and instructing the BDU accordingly

Together, the BDU and BMS form a robust safety and diagnostic framework that balances hardware isolation with software intelligence—critical for reliable EV battery management.

Integration Architectures and Communication

When it comes to BDU and BMS integration, there are two common architectures: distributed and centralized. In a distributed system, the BMS handles cell-level monitoring and decision-making, while the BDU acts as a separate high-voltage switch unit that executes physical disconnects. A centralized approach combines these functions more closely, sometimes incorporating the BDU and BMU into a single module along with sensors, improving response times and simplifying wiring.

Communication between the BMS/BMU and the BDU relies heavily on the CAN bus protocol. This real-time data exchange ensures the BMS can continuously monitor battery parameters and instantly command the BDU to open or close contactors as needed. The BMS also communicates with the Vehicle Control Unit (VCU) to align battery safety actions with broader vehicle operations.

For example, if the BMS detects an anomaly like overcurrent or voltage irregularities, it immediately sends a command to the BDU to disconnect the battery pack, preventing damage or hazards. Meanwhile, the BDU provides feedback to the BMS, confirming contactor status and diagnostic information—helping create a bidirectional safety loop that enhances battery protection.

This seamless integration between the battery disconnect unit and battery management system is increasingly important for meeting safety standards and supporting features like predictive maintenance. For deeper insights into effective system design and reduced manufacturing complexity, check out how battery pack integration cuts manufacturing cost.

How Integration Improves Battery Safety

Integrating the Battery Disconnect Unit (BDU) with the Battery Management System (BMS) significantly enhances EV battery safety through smart, real-time fault detection and rapid isolation. The BMS continuously monitors critical parameters like voltage, current, and temperature. When it detects issues such as overvoltage, short circuits, or crash events, it quickly sends a command to the BDU to disconnect the high-voltage circuit, preventing further damage or hazards.

This close collaboration also improves thermal runaway mitigation. By combining temperature and current sensing, the system can predict risks early and intervene before a dangerous escalation occurs, helping to avoid catastrophic battery failures. Additionally, system-level protection features like insulation resistance monitoring and the high-voltage interlock loop (HVIL) keep the battery pack safe and compliant with industry standards such as ISO 6469, UN ECE R100, and ASIL-D functional safety targets.

Integrated designs often include redundancy and fail-safe mechanisms, using dual sensors—like shunt and Hall-effect current sensors—and self-diagnostic capabilities. These features ensure that if one sensor fails, another can take over without compromising safety. Together, these advanced protections create a robust shield around the EV battery, making integrated BDU and BMS systems essential for reliable and safe electric vehicles.

For further details on how battery disconnect units boost EV safety, you can explore our in-depth coverage on battery disconnect units enhancing EV safety.

Series of LEAPENERGY Reliability Tests

Enhanced Diagnostics Through BDU-BMS Collaboration

When the Battery Disconnect Unit (BDU) and Battery Management System (BMS) work closely, diagnostics get a serious boost. Here’s how their collaboration enhances EV battery health and performance:

Advanced Monitoring Capabilities

- BDU sensors constantly track current, voltage, and temperature at the pack level.

- This real-time data flows directly into the BMS for precise, ongoing diagnostics.

- Helps spot subtle changes that might signal early battery issues.

Predictive Maintenance and Alerts

- Accurate State of Health (SOH) and State of Charge (SOC) estimates improve by combining BDU data with BMS algorithms.

- Enables early fault prediction before problems escalate.

- Supports remote monitoring through cloud integration, letting OEMs or fleet managers receive alerts anywhere, anytime.

Fault Logging and Root-Cause Analysis

- Every anomaly or fault triggers detailed event logging, captured by both BDU and BMS.

- This data supports:

- Post-incident diagnostics

- Warranty claims

- Continuous improvement of battery pack design and safety features

Benefits for OEMs

| Benefit | Description |

|---|---|

| Reduced Downtime | Faster fault detection means less time off the road. |

| Accelerated Troubleshooting | Clear data logs speed up pinpointing problems. |

| Extended Battery Life | Early interventions prevent deep damage and extend pack life. |

Together, the BDU-BMS integration creates a smarter, safer EV battery management ecosystem. This collaboration is essential for delivering reliable performance and boosting confidence in EV technology.

For a deeper dive into battery health and longevity, see our insights on 10 Things That Kill Your EV Battery Faster.

Practical Benefits and Industry Examples

Integrating the Battery Disconnect Unit (BDU) with the BMS/BMU offers several practical advantages that matter to EV manufacturers and users alike:

| Benefit | Explanation |

|---|---|

| Cost & Space Optimization | Fewer wiring runs, reduced components, and simpler assembly cut costs and save space inside battery packs. |

| Performance Gains | Faster fault response times and improved reliability support high-voltage architectures, including 800V+ platforms that enhance efficiency and charging speeds. |

| Real-World Applications | Leading EV platforms rely on integrated BDU-BMS setups for tighter safety control and smarter diagnostics under demanding conditions. |

One standout example is LEAPENERGY, which offers custom battery disconnect units designed for seamless integration with BMS solutions. Their engineering team brings deep expertise in high-voltage components, providing OEMs with tailored BDU designs that meet stringent safety and diagnostic requirements. This collaboration accelerates development cycles and ensures compliance with top industry standards.

For those interested, LEAPENERGY’s approach to 800V EV battery pack platforms delivers superior integration benefits, focusing on reliability and cutting-edge safety features that support the next generation of electric vehicles.

Explore more about LEAPENERGY’s innovative battery solutions and their impact on modern EV designs by visiting their pages on 800V EV battery platforms and custom EV battery packs.

By combining BDU and BMS intelligence, OEMs gain a competitive edge—with safer, more efficient, and easier-to-maintain battery systems.