Understand Your Project Requirements Before Supplier Evaluation

Before searching for the right Battery Disconnect Unit (BDU) supplier for your EV or ESS project, it’s crucial to clearly define your project’s needs. This step saves time and ensures the supplier’s solution matches your application perfectly.

Define Your Application Type

- Passenger EV: Compact size, low-to-medium voltage, high safety demands

- Commercial/Heavy-Duty EV: Higher voltage & current, rugged design, enhanced thermal management

- Stationary Energy Storage System (ESS): Long service life, strict environmental resilience

- Hybrid Systems: Complex integration with multiple voltage domains

Outline Key Electrical & Environmental Specs

| Parameter | Considerations |

|---|---|

| Voltage & Current | Max operating voltage & continuous current ratings |

| Environmental Rating | IP67, IP6K9K for water/dust resistance; temperature extremes (-40°C to 85°C or more) |

| Integration Needs | CAN communication support, BMS compatibility, Vehicle Control Unit (VCU) interface |

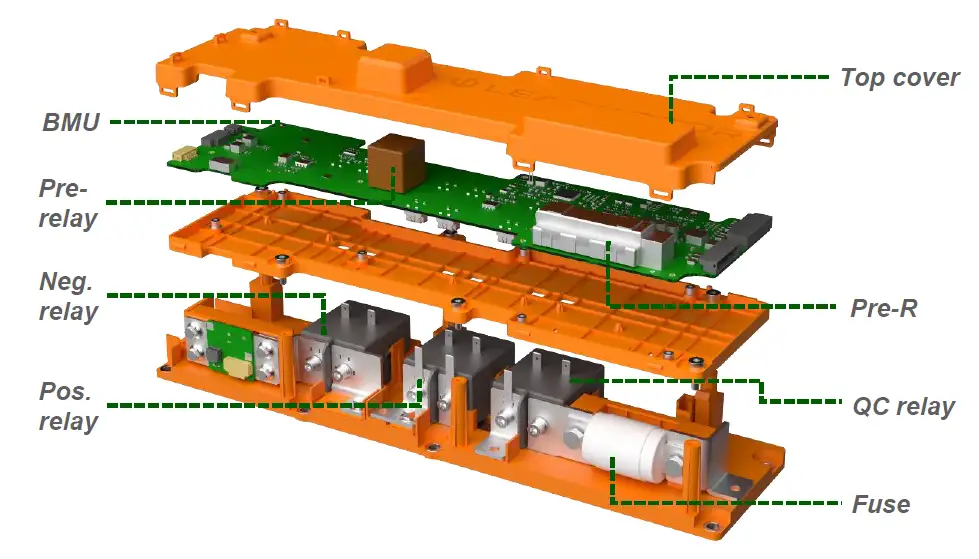

Identify Essential BDU Features

- Pre-charge circuits for smooth startup

- Main contactors & pyro fuses for reliable high-voltage switching and fault isolation

- Current sensors for real-time monitoring

- Redundant protection mechanisms to enhance safety

Match Supplier Selection to Project Phase and Volume

| Project Phase | Focus Areas |

|---|---|

| Concept | Flexibility, prototyping support |

| EVT/DVT/PVT | Custom engineering, robust validation |

| Mass Production | Scalability, supply chain stability, cost control |

Volume expectations also matter — whether you’re planning hundreds or thousands of units influences supplier capability and pricing models.

This upfront clarity helps narrow down your list of potential BDU manufacturers that offer the right combination of product specs, safety, and volume handling, making your EV or ESS project smoother and more successful.

Prioritize Safety and Compliance Expertise

When choosing a Battery Disconnect Unit supplier, safety and compliance should be non-negotiable. Make sure the supplier strictly follows functional safety standards like ISO 26262 ASIL B or D and IEC 61508. These certifications prove that the voltage BDU for EV and ESS projects meet the rigorous requirements for safe operation.

Also, check for recognized certifications such as UL 2580, UN 38.3, ECE R100, and GB/T standards—especially if your project targets global markets. A supplier with these credentials is more likely to offer a reliable BDU that handles fault detection and isolation effectively.

Critical features include thermal runaway mitigation and system-level protection logic designed to quickly disconnect high voltage during faults. Look for a proven track record in high-voltage disconnection under fault conditions to reduce risks and ensure battery safety control logic works as intended.

For deeper insight into battery safety standards related to BDUs, you can explore our detailed guide on EV battery pack standards driving safety.

Evaluate Technical Integration and Compatibility

When selecting a Battery Disconnect Unit (BDU) supplier for your EV or ESS project, technical integration and compatibility are crucial. Here’s what to focus on:

- Seamless BDU-BMS integrationEnsure the BDU supports smooth communication with your Battery Management System (BMS). This includes compatibility with CAN protocols and interaction with the Vehicle Control Unit (VCU) for efficient battery safety control and system management.

- High-voltage component qualityCheck the reliability of critical parts like contactors, fuses, and relays. High-quality sourcing reduces the risk of failure and improves overall system safety.

- Custom engineering supportLook for suppliers that offer flexibility in custom layouts, pin assignments, and alignment with your specific software or firmware needs. This level of customization helps optimize the battery pack design and integration.

- Advanced diagnostics: Confirm that the BDU provides real-time monitoring, fault logging, and predictive maintenance alerts to help detect issues early and avoid costly downtime.

| Key Integration Aspects | What to Verify |

|---|---|

| BDU-BMS Interface | CAN communication, VCU interaction |

| High-Voltage Components | Quality of contactors, fuses, relays |

| Engineering & Customization | Layout flexibility, pin assignments, firmware alignment |

| Diagnostic Features | Real-time data, fault logs, predictive signals |

A well-integrated BDU not only improves safety but also simplifies battery pack management and reduces integration effort. For more on optimizing your battery pack setup, see how battery pack integration cuts manufacturing cost.

Choosing the right Battery Disconnect Unit supplier with strong technical compatibility saves headaches and future-proofs your EV or ESS system.

Assess Customization and Engineering Capabilities

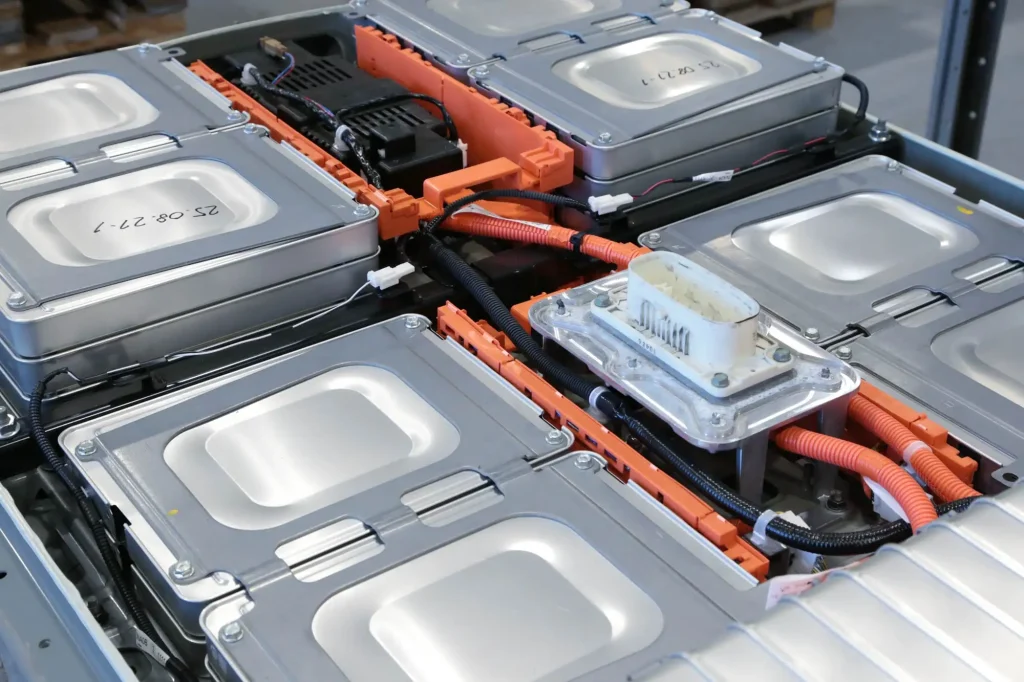

When selecting a Battery Disconnect Unit supplier for your EV or ESS project, customization is key. Look for a BDU manufacturer that can deliver OEM-specific solutions, such as compact “penthouse” units or fully integrated pack designs tailored to your battery layout. This flexibility helps optimize space and weight, critical factors for passenger EVs and heavy-duty applications alike.

Evaluate the supplier’s rapid prototyping and 3D modeling capabilities, ensuring they can quickly iterate designs and support testing phases. Engineering support that offers adjustments in pin assignments, enclosure materials like aluminum, stainless steel, or advanced composites, and structural modifications can make a big difference in meeting your project’s unique demands.

Prioritize suppliers who provide end-to-end customization—from initial concept through validation and production—so you have a seamless experience. These custom BDU solutions often integrate tightly with your Battery Management System (BMS) and vehicle control unit, streamlining OEM BDU engineering support and simplifying overall system integration.

For projects expecting to scale, consider partners who can handle both low-volume prototypes and move smoothly into mass production. For further insight, check how top global suppliers handle customization and prototyping at different production stages in EV battery pack development.

Analyze Manufacturing Quality, Scalability, and Supply Chain Stability

When choosing a Battery Disconnect Unit supplier for your EV or ESS project, manufacturing quality is non-negotiable. Look for suppliers with certified quality management systems like IATF 16949, which guarantees consistent process control and traceability throughout production. This ensures every BDU meets rigorous automotive standards.

Scalability is also key. Your supplier should be ready to support your project’s growth—from initial prototypes to full-scale, high-volume production—without compromising quality or lead times. A supplier with proven experience in scaling EV battery components can save you costly delays down the road.

Supply chain stability is another crucial factor. Make sure your BDU manufacturer has reliable component sourcing and strong risk mitigation plans in place, minimizing disruptions caused by shortages or geopolitical issues. Also, geographic location matters; suppliers close to major battery cell manufacturers or assembly plants can reduce shipping time and logistics costs, speeding up your project timeline.

For deeper insights on scaling from prototype to mass production, consider resources on scalability in EV battery pack production, which highlight the critical role of supply chain and manufacturing readiness in successful EV projects.

By focusing on these areas, you’ll secure a Battery Disconnect Unit supplier who can reliably support both your current needs and future growth.

Review Support, Testing, and Long-Term Partnership Value

Choosing the right Battery Disconnect Unit supplier for your EV or ESS project means looking beyond just the unit price. After-sales technical support is crucial—make sure your supplier offers reliable help for field failure analysis and clear warranty terms to protect your investment.

Also, check their validation testing capabilities, including environmental stress, vibration, EMC, and short-circuit tests, which are essential to ensure durability and safety under real-world conditions.

Look for suppliers with a strong innovation roadmap—supporting advanced systems like 800V+ architectures, Silicon Carbide (SiC) integration, or next-gen battery safety protection. This future-proofs your project and ensures compatibility with the latest tech trends.

Finally, consider the total cost of ownership: factor in integration effort, potential downtime risks, and ongoing lifecycle support. A supplier committed to long-term partnership can save costs and headaches down the road, providing value that goes beyond the battery pack disconnect unit itself. For projects needing close collaboration and custom solutions, strong OEM BDU engineering support can make all the difference.

Red Flags to Avoid When Selecting a BDU Supplier

When choosing a Battery Disconnect Unit supplier for your EV or ESS project, watch out for these warning signs:

- Limited high-voltage experience or no proven track record in EV or energy storage system protection will likely cause project delays and safety risks.

- Suppliers offering generic off-the-shelf products without real BDU customization may not meet your specific requirements or integration needs.

- Poor communication or slow responses during RFQ and technical discussions are red flags for potential support issues down the line.

- Suppliers lacking strong certifications, such as UL 2580 or ISO 26262 compliance, or without independent third-party validations, may not deliver reliable, safe solutions.

Picking a reputable, ISO 26262 compliant BDU manufacturer with proven expertise and clear communication is critical to avoid costly setbacks and ensure your battery pack disconnect unit fits your project smoothly. For a list of trusted options, see our overview of the top battery disconnect unit suppliers that emphasize quality and compliance.