The electric vehicle landscape is shifting fast—but one breakthrough stands at the forefront of this race: battery pack integration. As the demand for longer range, lower costs, and enhanced performance intensifies, traditional battery designs just can’t keep up. Today, advanced approaches like cell-to-pack (CTP) and cell-to-chassis (CTC) are not just technical upgrades—they’re becoming the biggest competitive advantage in EVs. If you want to understand how smarter integration drives bigger energy density, lighter weight, and manufacturing efficiency, you’re in the right place. Let’s dive into why this evolution matters more than ever.

The Evolution of EV Battery Pack Designs

Electric vehicle (EV) battery packs have come a long way from traditional modular designs. Early packs were built using several smaller modules, each containing groups of lithium-ion cells arranged within protective housings. While this modular structure helped with serviceability and safety, it also introduced significant limitations:

- Added weight from module casings and extra components

- Lower energy density due to space between modules

- Increased complexity in assembly and cooling

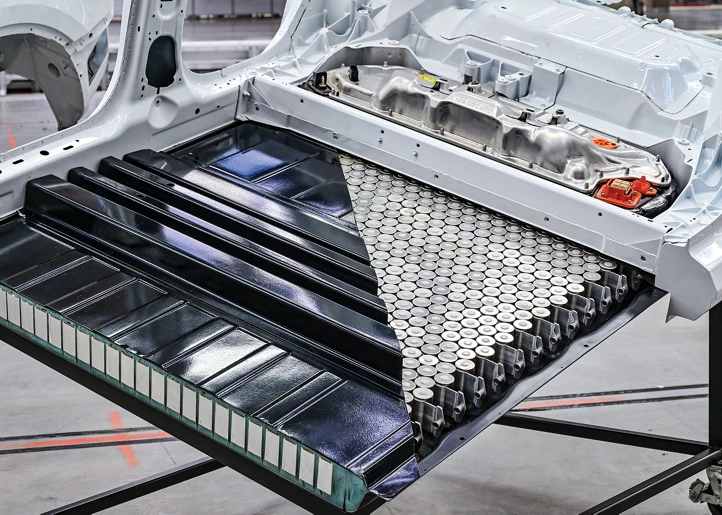

As energy storage demands grew, the industry shifted towards more integrated, module-less designs to boost performance and efficiency. This transition gave rise to cell-to-pack (CTP) technology, where cells are directly assembled into the battery pack without intermediate modules. The result is a slimmer, lighter pack with improved EV battery energy density.

Building on CTP, innovations like cell-to-chassis (CTC) and cell-to-body (CTB) went further, integrating the battery directly with the vehicle’s structure. This not only reduces weight but also enhances vehicle rigidity and safety.

Timeline of adoption:

- Early pioneers such as BYD introduced their blade batteries with a CTB approach in 2020, showcasing enhanced safety and packaging efficiency.

- Following these breakthroughs, major automakers and battery suppliers rapidly adopted CTP and CTC designs in 2026 and 2026 models, making advanced battery pack integration a new industry benchmark.

This evolution marks a significant step in optimizing battery performance, improving EV range and lowering pack weight, setting the stage for the competitive landscape we see today.

Key Technologies Driving Battery Pack Integration

Battery pack integration in EVs is mainly powered by two breakthrough technologies: Cell-to-Pack (CTP) and Cell-to-Chassis/Body (CTC/CTB). Both shift away from the traditional modular battery design and bring notable structural and performance improvements.

Cell-to-Pack (CTP): Simplifying Assembly for Efficiency

CTP removes the need for modules by assembling battery cells directly into the pack. This cuts down on parts and trim, increasing the battery’s energy density and reducing weight. Instead of fitting cells into separate modules, cells are packed tightly together with a unified cooling system and protective casing, streamlining production.

- Structural changes:

- No modules, fewer components

- Improved thermal management layouts

- Denser cell arrangement

This approach reduces the overall volume and mass of the battery pack, leading to better EV range and manufacturing cost savings.

Cell-to-Chassis/Body (CTC/CTB): Batteries as Vehicle Structure

CTC and its close cousin CTB take integration further by making the battery pack a structural component of the vehicle chassis or body. In other words, the battery isn’t just an addition—it helps form the frame. This enhances vehicle rigidity, reduces frame weight, and frees up interior space.

- Benefits:

- Adds chassis stiffness for better handling and crash safety

- Lowers vehicle center of gravity, boosting efficiency

- Cuts down weight by replacing traditional frame parts

Comparison at a Glance

| Feature | Modular Packs | Cell-to-Pack (CTP) | Cell-to-Chassis/Body (CTC/CTB) |

|---|---|---|---|

| Part count | High (modules + cells) | Reduced (no modules) | Lowest (pack + chassis combined) |

| Energy density | Baseline | +10-15% increase | +15-20% increase |

| Structural role | None | Battery pack only | Battery pack + vehicle structure |

| Manufacturing complexity | Moderate | Simplified assembly | Increased integration effort |

| Weight impact | Added module weight | Weight reduced | Significant weight reduction |

| Production implications | Standard process | Faster, cost-effective | Requires chassis redesign |

These advances are driving the next wave in EV battery design, balancing efficiency, performance, and cost. For more in-depth insights into how CTP and CTC technology elevate EV battery performance, the evolving landscape is worth watching closely.

By integrating batteries directly into the vehicle structure, manufacturers improve overall pack reliability and open new paths for EV innovation while keeping costs competitive.

Core Competitive Advantages of Advanced Battery Pack Integration

Advanced battery pack integration in EVs delivers several key benefits that give manufacturers a real edge in today’s competitive market:

Higher Energy Density and Extended Range

- More cells packed efficiently means 10-20% more driving range without making the battery bigger.

- Optimizing cell layout eliminates wasted space found in traditional modular packs.

Weight Reduction and Efficiency Gains

- Lighter battery packs reduce overall vehicle weight.

- This improves handling, acceleration, and energy consumption, making EVs more efficient on the road.

Cost Savings in Manufacturing

- Advanced integration cuts the number of parts by up to 40%, trimming material costs.

- Simplified assembly processes speed up production and enhance scalability, reducing labor expenses.

Improved Safety and Thermal Management

- Better heat dissipation lowers the risk of thermal runaway.

- Battery packs meet or exceed EV battery safety standards like UL 2580 and IEC 62660 for safer operation.

Structural and Design Benefits

- Integrating the battery as a structural component stiffens the chassis.

- This lowers the center of gravity and frees up interior space, allowing more room for passengers or cargo.

| Advantage | Benefit | Impact |

|---|---|---|

| Higher Energy Density | 10-20% longer range without bigger pack | Better range, competitive edge |

| Weight Reduction | Lighter pack improves handling and efficiency | Enhanced driving dynamics |

| Manufacturing Cost Savings | Up to 40% fewer parts, simpler assembly | Lower production costs |

| Safety & Thermal Management | Improved cooling, reduced fire risks | Compliance with safety standards |

| Structural Design | Stiffer chassis, lower center of gravity | Improved stability and space |

These combined advantages make cell-to-pack (CTP) and cell-to-chassis (CTC) integration a must-have for EV manufacturers wanting to stand out. For more details on key safety features in modern EV battery packs, you can visit our detailed guide on key safety features in EV battery packs.

Real-World Impact: Case Studies from Leading Players

Battery pack integration has already reshaped how top EV makers compete on range, safety, and cost. Take BYD, for example. Their blade battery combined with the Cell-to-Body (CTB) approach cuts down pack weight and parts count, offering a standout edge in cost leadership and safety. By turning the battery into a structural component, BYD improves crash protection and heat management, making their packs both tough and efficient.

Tesla is another major player pushing the envelope with structural battery packs in models like the Model Y and Cybertruck. Tesla’s integration strategy enhances vehicle rigidity and speeds up production by simplifying assembly. This approach also supports faster charging rates and longer cycle life, giving Tesla an advantage in performance and durability.

Other global leaders like CATL and LG Energy Solution are quickly adopting CTP and CTC technologies. They are working closely with global OEMs to scale these innovations, improving not just battery energy density but also enabling faster fleet optimization. More integrated packs help extend EV range without increasing size, which is a significant advantage for both passenger and commercial electric vehicles.

These real-world examples highlight how smarter battery pack integration is key to achieving cost savings, meeting rigorous EV battery safety standards, and boosting overall vehicle efficiency. For a deeper dive into these integration trends, checking out a detailed EV battery pack guide for 2026 offers valuable insights into current and future industry moves.

Challenges and Trade-Offs in Advanced Battery Pack Integration

While advanced battery pack integration offers many benefits, it also brings several challenges that automakers and suppliers must navigate.

- Manufacturing Complexity: Moving from traditional offline assembly to integrated battery pack production, especially with cell-to-pack (CTP) and cell-to-chassis (CTC) designs, requires new manufacturing processes and equipment. This shift can slow production ramp-up and increase upfront costs.

- Repairability and Serviceability: Integrated packs are often harder to repair or replace. Unlike modular packs where damaged modules can be swapped out, structural battery packs mean more complexity and potential downtime during maintenance.

- Material and Safety Requirements: Using batteries as structural components demands higher standards for material strength and compliance with EV battery safety standards like UL 2580 or GB/T. These packs must manage thermal stresses and crash forces without compromising safety.

- Balancing Cost and Performance: For passenger EVs, the focus is on maximizing energy density and range, whereas commercial electric vehicles prioritize durability and high-capacity packs. Designing integrated battery packs that meet these diverse needs while staying cost-effective is a tough balance.

Addressing these challenges means combining advanced manufacturing technologies with smart design choices and robust battery management systems (BMS). For more on safety and system integration, check out this detailed overview of how battery disconnect units enhance EV safety during operation.

Future Trends: What’s Next for Battery Pack Integration

Looking ahead to 2026 and beyond, battery pack integration in EVs is set to grow deeper and more sophisticated. Wider adoption of Cell-to-Chassis (CTC) designs will continue as more manufacturers recognize the benefits of using the battery as a structural part of the vehicle. Expect hybrid approaches too—combining traditional modular elements with advanced cell-to-pack (CTP) and CTC techniques to balance cost, safety, and performance.

Solid-state battery compatibility is another major trend on the horizon. These batteries promise higher energy density and improved safety, but their success depends heavily on how well they can be integrated structurally—something advanced pack designs are gearing up to support.

Key to all these developments will be smarter, more advanced Battery Management Systems (BMS). These systems optimize cycle life, improve battery consistency, and manage thermal profiles more effectively, boosting both safety and efficiency. Lightweight materials will also play a crucial role in reducing pack weight without compromising strength, helping with overall EV range optimization.

Sustainability is becoming a core focus as well. Future integrated battery packs will be designed for easier recycling and second-life applications, addressing both environmental concerns and cost efficiency. This shift supports long-term sustainability goals in the U.S. market, where eco-conscious consumers expect responsible manufacturing.

Manufacturers like LEAPENERGY are at the forefront of these trends, innovating high-capacity, structurally integrated battery packs that prioritize both safety and performance. Their work highlights how vertical integration—from cell to pack to vehicle—is essential for meeting the demands of modern EVs. For a deep dive into current and upcoming battery pack technologies, check out our detailed guide on electric battery pack design and technology trends.

By combining these advances, the EV industry is poised to deliver safer, lighter, and more powerful battery solutions that align perfectly with U.S. consumers’ needs for performance, affordability, and sustainability.