Core Design Priorities for Passenger Car Battery Packs

Designing EV battery packs for passenger cars means balancing multiple critical priorities to deliver an optimal driving experience. Here’s what stands out:

Maximizing Energy Density and Vehicle Range

Energy density is king when it comes to passenger vehicle battery integration. Higher battery pack energy density allows more power storage in a compact, lightweight battery pack. This translates directly to EV range optimization—giving drivers longer trips between charges without increasing vehicle size or weight.

Ensuring Safety and Thermal Stability

Safety is non-negotiable. Battery packs must comply with rigorous EV battery safety standards like UL 2580 and IEC 62660 while preventing thermal runaway risks. Effective EV thermal management systems and robust pack packaging design ensure thermal stability and minimize hazards under normal use and crash scenarios.

Reducing Costs and Simplifying Manufacturing

Lowering manufacturing costs is vital for making EVs affordable and scalable. Simplifying battery pack integration—moving toward cell-to-pack (CTP) designs—and using modular architectures help streamline production. Cost pressures also drive the adoption of scalable assembly processes and standard testing per UN 38.3 battery testing guidelines.

Enhancing Charging Speed and Convenience

Fast charging battery packs improve usability by reducing wait times. Designs focus on high-voltage battery architecture to support rapid charging without compromising battery life or safety. Enhancing convenience also means ensuring compatibility with public and home charging stations.

Achieving Longevity and Durability

Long cycle life battery packs are essential for sustained performance over years of use. Battery cycle life optimization techniques, like advanced BMS algorithms and state of health (SOH) monitoring, keep the battery pack consistent and balanced. Durability also means withstanding real-world stresses without rapid degradation.

By understanding and prioritizing these core elements, EV battery packs for passenger cars can deliver high performance, safety, and affordability—key to accelerating EV adoption.

Major Challenges in Battery Pack Design

Designing EV battery packs for passenger cars comes with several key challenges that manufacturers must carefully balance.

Thermal Management and Runaway Risks

Keeping battery temperatures in check is critical. Poor EV thermal management can lead to overheating and, in worst cases, thermal runaway—a dangerous, self-sustaining reaction. Effective cooling systems and fire prevention measures are essential to meet safety standards and protect passengers.

Balancing Energy Density with Safety and Weight

Pushing for higher battery pack energy density means more power and longer EV range but often adds complexity. Increasing capacity without compromising safety or adding too much weight requires smart cell-to-pack (CTP) designs and lightweight battery pack engineering.

Regulatory Compliance and Testing Standards

EV battery packs must pass strict regulatory tests, such as UN 38.3 battery testing and meet EV battery safety standards like IEC 62660, ISO 6469, UL 2580, and GB/T standards in the U.S. market. Compliance ensures reliability but can add cost and design constraints.

Manufacturing Scalability and Cost Pressures

Bringing advanced battery pack packaging to scale while controlling costs is a big hurdle. Simplifying manufacturing processes without sacrificing quality or consistency is necessary to meet growing demand and stay competitive.

Degradation, Consistency, and End-of-Life Considerations

Battery cycle life optimization involves maintaining performance over thousands of charge cycles. Managing battery degradation mechanisms and ensuring uniform cell balancing contribute to better state of health (SOH) and reliable EV battery performance from day one to end-of-life.

For a deeper dive into how these safety and design challenges are handled, check out our detailed overview of key safety features in EV battery packs. Also, our comprehensive EV battery pack guide covers the evolving challenges and solutions shaping tomorrow’s passenger vehicle battery packs.

Emerging Architectural Trends and Innovations

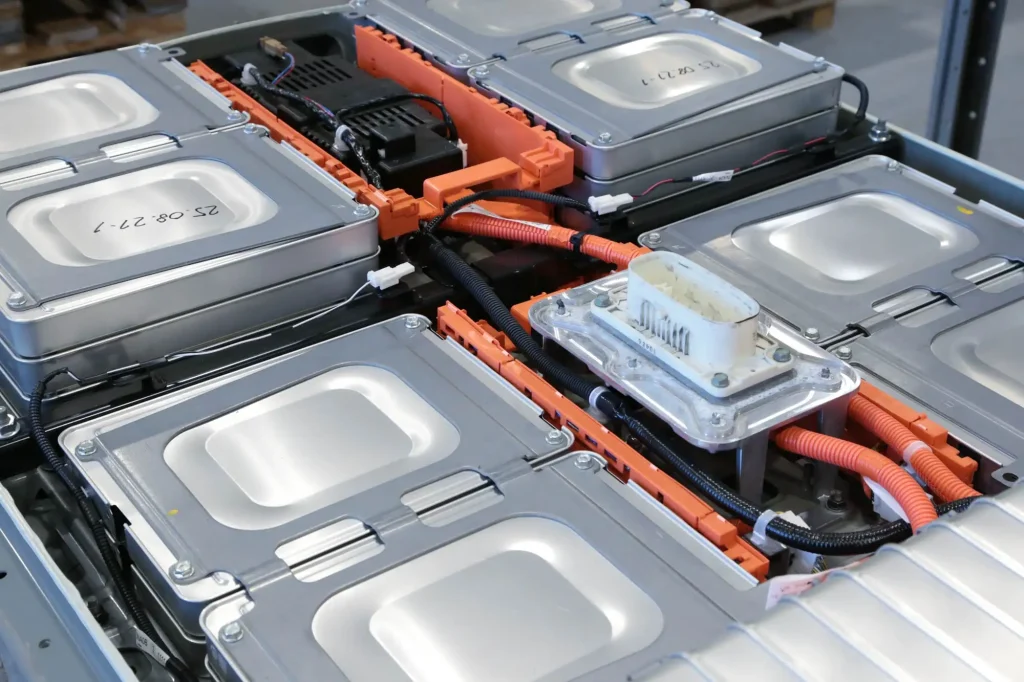

The design of EV battery packs for passenger cars has evolved significantly, moving beyond the traditional Cell-to-Module-to-Pack (CTMP) approach. Today, advanced integrations like Cell-to-Pack (CTP) and even Cell-to-Chassis (CTC) are gaining traction. These architectures eliminate intermediate modules, reducing weight and increasing battery pack energy density, which directly helps with EV range optimization and lightweight battery pack design.

Different cell formats—cylindrical, prismatic, and pouch—continue to impact pack design. Pouch cells, for instance, offer flexible packaging and better space utilization, while cylindrical cells provide robustness and easier thermal management. Choosing the right cell format shapes how well a pack can balance energy density with safety and thermal stability.

Advanced Battery Management Systems (BMS) are critical in modern EV battery packs. They use sophisticated algorithms for state of health (SOH) monitoring, cell balancing techniques, and real-time thermal monitoring to prevent thermal runaway and optimize battery cycle life. These smart BMS solutions enhance safety, extend durability, and ensure consistent performance across a battery pack’s life.

LEAPENERGY stays ahead by incorporating these architectural trends and innovations. They focus on integrating high-quality lithium-ion cells into efficient pack designs paired with cutting-edge BMS technology. By doing so, LEAPENERGY tackles key priorities such as thermal management, fast charging capabilities, and cost-effectiveness while meeting EV battery safety standards. Their approach is detailed in their work on module-to-pack integrated EV battery systems and the latest EV battery pack technology types and trends, showing how innovation drives better passenger vehicle battery pack solutions.

Future Outlook: Trends Shaping Passenger EV Battery Packs

The future of passenger car battery packs is heading toward higher integration and improved material efficiency. Manufacturers are focusing on designs that merge cells directly into the pack or even the vehicle chassis, like cell-to-pack (CTP) and cell-to-chassis (CTC) architectures. This reduces weight and volume, allowing for greater energy density without increasing the pack’s size—key for enhancing EV range optimization in everyday U.S. driving conditions.

Advanced battery chemistries will play a bigger role too. Moving beyond traditional lithium-ion cells, new formulations promise faster charging, higher capacity, and better durability. Complementing this, modular battery designs make it easier to repair and upgrade packs, extending vehicle life and simplifying recycling efforts.

Sustainability and performance go hand in hand. The future pack will balance battery cycle life optimization with stricter EV battery safety standards, meeting regulations like UL 2580 and UN 38.3. Innovations in advanced BMS algorithms will monitor the pack’s state of health (SOH) more precisely, improving safety and longevity.

For a detailed look at evolving battery pack strategies and how innovations are shaping the market, check out LeapEnergy’s in-depth analysis of the global EV battery pack market outlook. Understanding these trends is crucial for anyone interested in high-performance, reliable battery solutions for passenger EVs.