Why Certifications Matter for EV Battery Packs

When working with EV battery packs, understanding the importance of certification is crucial. These certifications ensure safety, reliability, and compliance with global regulations—key factors for both manufacturers and buyers.

Key Risks in EV Batteries

EV batteries face several critical risks that certification helps mitigate:

- Thermal runaway: Uncontrolled temperature rise can lead to fires or explosions.

- Electrical faults: Short circuits or overcharging may damage cells or the entire pack.

- Transportation hazards: Shipping lithium-ion batteries poses risks like impact or temperature extremes.

- Functional failures: Faulty battery management systems (BMS) could cause malfunctions or safety issues.

Global Regulatory Requirements

For EV battery packs to enter and compete in the global market, they must meet various international regulations:

| Region | Certification Examples | Focus |

|---|---|---|

| Worldwide | UN38.3 | Safe transport of lithium batteries by air, sea, and road |

| European Union (EU) | CE marking | Product safety and environmental compliance |

| North America | UL certification (e.g., UL 2580) | Electrical safety and performance standards |

These certifications aren’t optional—they’re mandatory for legal and safe operation.

Benefits of Compliance

Achieving compliance with these standards offers significant advantages:

- Reduced liability: Compliance lowers the risk of accidents and legal issues.

- Faster market entry: Certified products pass inspections quicker and gain approval smoothly.

- Enhanced reliability: Tested batteries perform better and last longer.

- Buyer confidence: Certification signals quality and safety to OEMs, fleet operators, and consumers.

Impact on OEMs and Suppliers

For original equipment manufacturers and suppliers of EV battery packs, certifications help:

- Avoid costly recalls driven by safety failures.

- Meet automotive-grade demands required by major car makers.

- Streamline supplier approval by demonstrating reliable, tested products.

- Build stronger partnerships with vehicle manufacturers focused on safety and durability.

Table: Why EV Battery Pack Certification Matters

| Aspect | Key Reason |

|---|---|

| Safety | Prevent thermal runaway, electrical faults, and accidents |

| Legal Compliance | Meet UN38.3, EU/CE, UL, and other global regulations |

| Market Access | Enable worldwide transport, sales, and use |

| Brand Reputation | Enhance trust and reduce liability |

| Operational Reliability | Ensure consistent performance and avoid functional failures |

Certifications create a safer, smoother path to market for custom EV battery packs and standard products alike. Understanding these standards early allows for better design and reduces surprises down the production line.

UN38.3: Transportation Safety Standard for EV Battery Packs

UN38.3 is a mandatory global standard designed to ensure the safe transport of lithium-ion batteries by air, sea, and road. This certification applies to EV battery pack testing at all levels—from individual cells to modules and full battery packs—making it vital for any OEM or manufacturer in the U.S. market.

Purpose and Scope

The purpose of UN38.3 is to prevent accidents during shipping caused by battery failures. It covers key risks like thermal runaway, short circuits, and mechanical damage that can occur during transport.

Key Tests (T1–T8)

To pass UN38.3, batteries must clear eight rigorous tests simulating real-world hazards:

| Test Code | Description | Focus |

|---|---|---|

| T1 | Altitude Simulation | Low pressure to mimic air travel |

| T2 | Thermal Shock | Rapid temperature changes |

| T3 | Vibration | Transport movement shocks |

| T4 | Shock | Drop impacts |

| T5 | External Short Circuit | Electrical shorts outside pack |

| T6 | Impact/Crush | Mechanical damage |

| T7 | Overcharge | Excess voltage scenarios |

| T8 | Forced Discharge | Battery discharge under fault |

Application to EV Battery Packs

UN38.3 certification is required not only for cells but also for modules and complete EV battery packs. This means your battery management system and pack design need to meet strict safety criteria to pass.

Certification Process

- Testing labs accredited for UN38.3 run the required tests.

- Complete documentation and test summaries must be submitted.

- Results must prove compliance before batteries can be shipped legally.

Common Challenges and Tips for Compliance

- Sample Preparation: Test samples must replicate production models exactly to avoid test failures.

- Documentation: Keep detailed data on materials and manufacturing processes.

- Timing: Testing can take several weeks, so start early to meet shipping deadlines.

- Retesting: Any design changes usually require retesting.

Understanding and meeting UN38.3 requirements is critical for safe, legal shipping of EV battery packs in the U.S. and worldwide. For a deeper insight into safety features and design strategies, check out our guide on key safety features in EV battery packs.

IEC 62660 Series: Performance and Safety for Propulsion Cells

The IEC 62660 series focuses on performance and safety specifically for lithium-ion cells used in electric vehicle battery packs. It’s divided into three key parts:

- IEC 62660-1: Covers performance testing such as capacity, efficiency, and cycle life to ensure cells meet the demands of EV propulsion.

- IEC 62660-2: Deals with reliability and abuse tests, checking how cells respond to stresses like vibration, shock, and temperature extremes.

- IEC 62660-3: Defines safety requirements, including protection against overcharge, internal short circuits, and thermal propagation within cells.

This standard is crucial because detailed cell-level data helps OEMs and suppliers design and validate reliable EV battery packs. Testing procedures cover everything from measuring capacity fade over many charge cycles to abuse scenarios that simulate real-world failures, with clear acceptance criteria to pass certification.

Additionally, IEC 62660 testing aligns with pack-level standards, bridging the gap between individual cell performance and the overall battery pack safety and functionality. This integration ensures high-voltage battery systems meet rigorous automotive requirements for performance and reliability. For an in-depth look at how these tests support full battery pack compliance, check out our EV battery pack guide explained.

ISO 26262: Functional Safety for Automotive Systems

ISO 26262 is all about managing electrical and electronic safety risks in road vehicles, including EV battery packs. It uses a risk-based approach to make sure systems like Battery Management Systems (BMS) work safely, even if something goes wrong.

What You Need to Know About ISO 26262

| Aspect | Details |

|---|---|

| Risk Approach | Focuses on preventing systematic failures, unlike abuse testing standards. |

| ASIL Ratings (A–D) | Automotive Safety Integrity Levels categorize risk severity. BMS usually falls in ASIL B or higher. |

| Key Processes | – Hazard Analysis and Risk Assessment (HARA) – Defining Safety Goals – Developing Functional and Technical Safety Concepts |

| Battery Pack Implications | – Fault detection mechanisms – Redundancy in BMS to avoid failures – Mitigation of thermal and electrical hazards |

ISO 26262 pushes OEMs and suppliers to design EV battery packs with safety built-in, not as an add-on. This means making sure the BMS can detect faults early and handle problems without leading to dangerous failures like thermal runaway.

How ISO 26262 Stands Apart

While other standards, like UN38.3 or IEC 62660, focus on physical abuse or performance testing, ISO 26262 zeroes in on systematic design issues that could cause failures in operation. This makes it crucial for automotive-grade battery pack validation and battery management system certification, especially for U.S. markets where functional safety is key.

For more detailed comparisons on global standards and suppliers, check out our guide on the top EV battery pack suppliers.

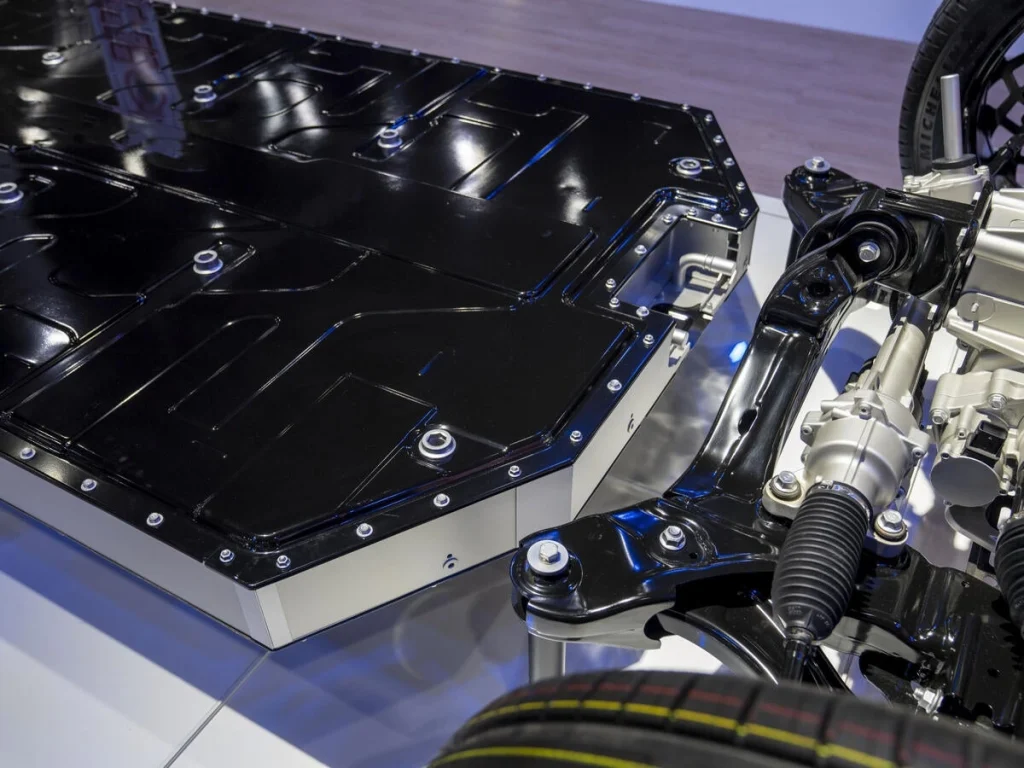

How These Standards Apply to Complete EV Battery Packs

EV battery pack certification isn’t just about the cells inside; it’s about the entire system working safely and reliably. The data from IEC 62660, which focuses on cell-level performance and safety, serves as a foundation for validating modules and full battery packs. This bridging ensures that individual cells meet quality thresholds before being integrated into larger battery assemblies.

Beyond IEC 62660, complementary standards like ISO 12405 target pack-level performance, while UL 2580 addresses system safety and electrical hazards in high-voltage battery packs. These standards work together to cover all aspects—from cell chemistry to the entire battery system.

The testing hierarchy follows a clear path: Cell → Module → Pack → Vehicle integration. Each level involves specific evaluations to catch issues early, avoid failures, and comply with strict automotive safety requirements. For example, abuse testing of cells per IEC 62660 informs protective measures within the pack, while ISO 26262 ensures functional safety at the system level.

In real-world applications, automotive OEMs and EV battery pack manufacturers who comply with these layered standards see fewer recalls and better performance in high-voltage battery systems. They also accelerate time-to-market by meeting global regulatory demands head-on. For insights on market trends and supplier roles, check out this global EV battery pack market outlook.

Successful certification relies on understanding how these standards interlock to deliver safe, reliable, and high-performing EV battery packs.

Step-by-Step Certification Process

Certifying an EV battery pack involves a clear, organized approach to meet all required standards like UN38.3, IEC 62660, and ISO 26262. Here’s a straightforward breakdown:

Planning and Documentation

Start with a solid safety management plan and detailed test plans tailored for lithium-ion battery safety standards. Proper documentation helps streamline communication and ensures every risk gets addressed early.

Selecting Accredited Labs and Preparing Samples

Choose labs accredited for EV battery pack testing to guarantee valid results. Prepare your battery cells, modules, or full packs according to the lab’s specifications to avoid delays.

Timeline and Costs

Certification usually takes 4 to 12 weeks per standard, depending on test complexity and sample readiness. Costs fluctuate based on the number of tests, lab fees, and any retests needed after failure. Budget accordingly to avoid surprises.

Post-Certification

Once approved, your pack receives certification marking and declarations essential for regulatory compliance and market entry. Ongoing compliance means regular audits and updates to stay aligned with evolving safety requirements.

For OEMs looking to simplify this process, partnering with experienced suppliers like LEAPENERGY can save time and risks. They offer custom EV battery designs, in-house testing, and full certification assistance, making it easier to meet the standards necessary for US and global markets. Learn more about their solutions on the products page.

Best Practices for Achieving Compliance

Achieving certification for EV battery packs starts early—right from the design phase. Incorporating safety and regulatory requirements into your battery pack design helps avoid costly revisions later. Focus on thermal management, robust battery management systems (BMS), and modular designs that simplify testing and validation.

Partnering with experienced manufacturers who understand UN38.3 transportation testing, IEC 62660 compliance, and ISO 26262 functional safety can save time and reduce risks. These experts build compliance into the product from the ground up, ensuring smoother certification processes and higher-quality battery packs.

At LEAPENERGY, we support OEMs by offering custom EV battery pack designs tailored to meet strict safety and performance standards. With our in-house EV battery pack testing capabilities and full certification assistance, we streamline your path to market. Whether you’re sourcing an automotive battery pack or need help navigating the certification process, LEAPENERGY’s expertise helps you deliver reliable, certified products with confidence.

For a deeper dive on manufacturers that prioritize compliance, check out our top EV battery pack manufacturers in the US and see how quality and safety come together in every pack.