If you think an electric battery pack is “just a big battery,” you’re missing the real story.

This is the heart, brain, and nervous system of every modern EV, e‑bike, energy storage system, and even next‑gen aircraft. It quietly determines range, charging speed, safety, lifetime, and total cost of ownership—yet most people only look at kWh and price.

Meanwhile, global demand for EV battery packs is exploding toward the terawatt-hour era,

What Is an Electric Battery Pack?

Simple Definition

An electric battery pack is the complete “fuel tank” of an EV or electric device.

It’s not just one big battery. It’s a system made of many smaller cells plus electronics, cooling, and safety parts, all working together to store and deliver energy safely and efficiently.

If a single battery cell is a Lego brick, the battery pack is the finished Lego model with structure, wiring, and controls.

Battery Pack vs Single Battery Cell

A battery cell is the smallest building block.

A battery pack is a structured assembly of:

- Many cells connected in series and parallel

- A battery management system (BMS)

- Cooling / thermal management

- High‑voltage wiring and safety components

- A protective enclosure / housing

A single lithium-ion cell might power a flashlight.

A high-voltage battery pack made from thousands of cells powers an entire electric vehicle.

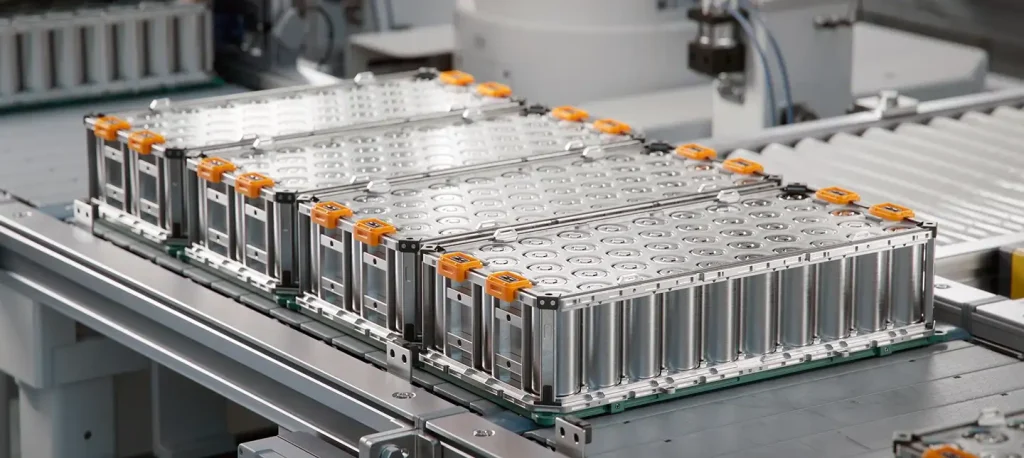

Cell, Module, and Pack in Real Life

In most EVs, we build up energy like this:

- Cell –

Like a single AA, but lithium-ion: cylindrical, prismatic, or pouch.

Example: one 3.7 V, 5 Ah cell. - Module –

A group of cells packaged together.

Example: 12 cells combined to reach a higher voltage and capacity. - Pack –

Multiple modules plus BMS, cooling, wiring, and housing.

Example: 300–400 V EV battery pack in a car or a traction battery pack in a forklift.

Same idea in smaller devices:

- E-bike pack = tens of cells + BMS + casing

- Power tool pack = a few cells + simple BMS + plastic housing

What the Battery Pack Actually Does

In an EV or energy storage system, the lithium-ion battery pack is responsible for:

- Storing energy (measured in kWh)

- Delivering power to the motor, inverter, or load

- Receiving energy during charging and regenerative braking

- Protecting cells from overcharge, over-discharge, overcurrent, and overheating

- Communicating with the vehicle or device via the BMS and CAN network

If the motor is the muscles, the battery pack is both the stomach and the circulatory system—it holds the “food” (energy) and manages how it flows.

Why Battery Pack Design Matters

The way we design the battery pack directly affects:

- Range –

How many kWh we fit into a safe, compact space (energy density battery pack design). - Power and performance –

How much current the pack can safely deliver (C-rate, wiring layout, EV battery cooling system). - Safety –

How the pack handles crashes, short circuits, and potential thermal runaway. - Durability and cycle life –

How many years and miles the pack can last before noticeable battery pack degradation. - Charging experience –

Whether the pack supports fast charging EV battery standards and high-voltage 400V or 800V battery architecture.

As a battery engineer and pack manufacturer, I treat battery pack design as the core of the EV: it decides how far you go, how fast you charge, and how safe you are.

Electric Battery Pack Components

When I design an electric battery pack, I’m really building a complete system, not just stacking cells. Every part below affects range, power, safety, and cost.

Battery Cells: Cylindrical, Prismatic, and Pouch

The “fuel” of any EV battery pack is its cells:

- Cylindrical cells (like 21700, 4680):

- Great for high power, good cooling, very robust.

- Common in performance EVs and power tools.

- Prismatic cells:

- Rectangular cans, easier to pack tightly for higher energy density.

- Popular in mainstream EVs and energy storage.

- Pouch cells:

- Flexible “foil bag” format, very high energy per liter, but need strong mechanical support.

- Used where space is tight and weight matters.

We choose format based on the use case: power vs range, cost targets, and available space in the vehicle or storage cabinet.

Battery Management System (BMS)

The battery management system (BMS) is the brain of the high‑voltage battery pack. It:

- Monitors voltage, current, and temperature of every cell group.

- Balances cells to keep them at the same state of charge.

- Protects against overcharge, over-discharge, short circuit, and over‑temperature.

- Communicates with the vehicle or inverter to control power and charging.

Without a solid BMS, even the best lithium-ion cells will degrade faster and can become unsafe. BMS design and software are one of the main differentiators for a quality pack.

Thermal Management: Air vs Liquid Cooling

Heat kills battery life. A modern EV battery pack needs a proper thermal management system:

- Air cooling:

- Simpler, cheaper, lighter.

- Works for low to mid‑power packs (e‑bikes, small EVs, some storage).

- Less uniform temperature and slower heat removal.

- Liquid cooling:

- Uses coolant channels, plates, or jackets.

- Essential for fast charging, high power, and extreme climates.

- Keeps cells in a tight temperature window, improving cycle life and safety.

We often combine advanced liquid cooling with smart airflow. If you want a deeper dive, I’ve broken down the tradeoffs in this guide on liquid vs hybrid cooling for EV batteries and why it matters for pack life and fast charging: liquid and hybrid cooling in EV battery packs.

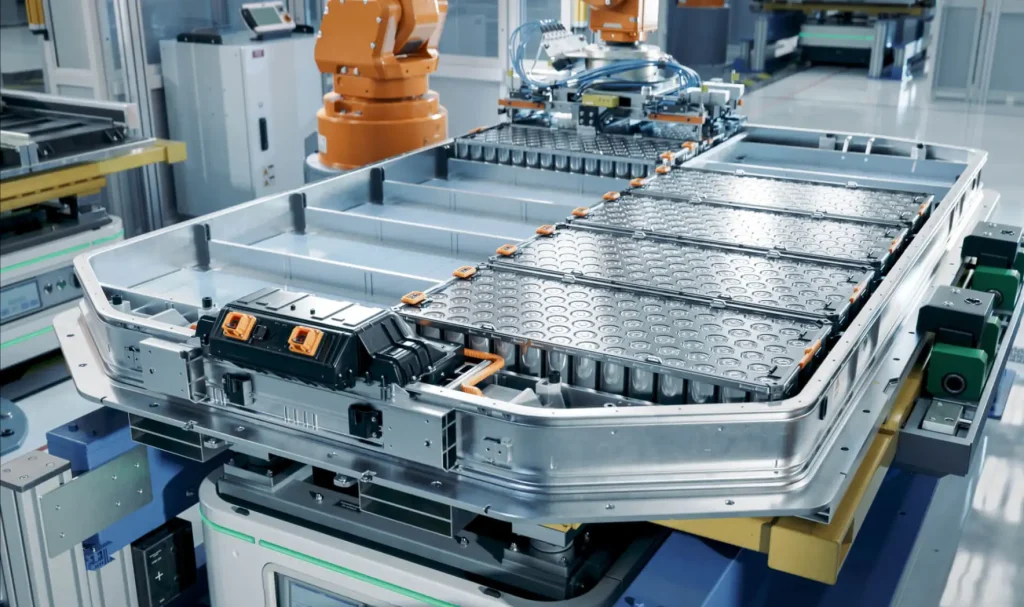

Pack Housing, Enclosure, and Crash Structure

The battery pack enclosure is both a shell and a safety system:

- Sealed aluminum or steel housing to keep out water, dust, and road debris.

- Crash structure and reinforcements to protect cells in front, side, and underbody impacts.

- Firewall and venting paths to manage gases if a cell goes into thermal runaway.

- Integrated mounting points so the pack can be safely bolted into the vehicle or cabinet.

In the U.S., we design around NHTSA crash expectations, road salt, wide temperature swings, and long‑term corrosion resistance.

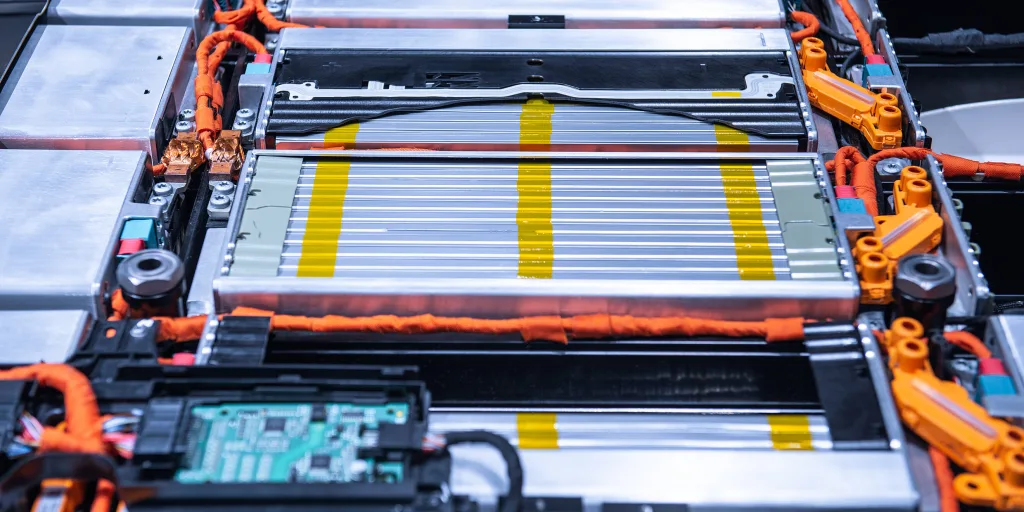

High‑Voltage Wiring, Busbars, and Connectors

Inside a high‑voltage battery pack, the current paths matter just as much as the cells:

- Busbars (usually copper or aluminum) connect cell groups with low resistance and high mechanical strength.

- High‑voltage cabling routes power to inverters, DC‑DC converters, and chargers.

- Connectors are rated for high current and vibration, with secure locking and sealing.

- Proper creepage and clearance distances are critical for safety at 400V or 800V.

Good busbar and wiring design cuts losses, improves efficiency, and reduces heat at high loads.

Sensors, Control Units, and CAN Communication

Modern EV battery packs are fully networked systems:

- Sensors:

- Voltage taps on cell groups.

- Multiple temperature sensors across modules and coolant loops.

- Current sensors and isolation monitors.

- Control units:

- Main BMS control board.

- Module-level monitoring units for large traction battery packs.

- CAN communication:

- The pack talks to the vehicle or energy storage controller via CAN bus.

- Shares data on state of charge (SoC), state of health (SoH), temperature, faults, and limits.

- Enables over‑the‑air updates and remote diagnostics.

We design our packs so they drop cleanly into modern EV and ESS platforms using standard CAN messages and protocols. For OEMs moving to more integrated architectures, I’ve outlined how module‑to‑pack and cell‑to‑pack strategies change the internal layout here: module-to-pack integrated EV battery systems.

Battery Chemistries in Modern Electric Battery Packs

When we talk about an electric battery pack, we’re really talking about its chemistry. Chemistry drives range, safety, cost, and how long the pack lasts.

Lithium‑ion Basics for EV Battery Packs

Most EVs today use some form of lithium‑ion battery pack because it delivers a strong mix of:

- High energy density – more miles per kWh

- Good power – strong acceleration and fast charging

- Decent cycle life – thousands of charge cycles with the right BMS and cooling

Under the hood, “lithium‑ion” is a family of chemistries, not just one formula.

NMC EV Battery Packs (Nickel Manganese Cobalt)

NMC battery packs are currently the workhorse chemistry in many U.S. EVs.

Pros:

- High energy density → more range in the same space

- Good balance of performance and longevity

- Well understood, lots of real‑world data

Cons:

- Uses cobalt and nickel → higher cost and sourcing concerns

- Needs tighter thermal management and BMS monitoring and control to stay safe and healthy

Best for:

- Mid‑ to long‑range passenger EVs

- Fleets where range and weight really matter

LFP Battery Packs (Lithium Iron Phosphate)

LFP battery packs are exploding in popularity in the U.S. because they’re:

- Safer (more tolerant to abuse, lower fire risk)

- Long‑life (high cycle life, slower degradation)

- Lower cost per kWh (iron vs nickel/cobalt)

Trade‑offs:

- Lower energy density → heavier and larger for the same range

- Slightly lower cold‑weather performance (needs smart pack design and pre‑conditioning)

Best for:

- Daily commuters, city EVs, work trucks with predictable routes

- Energy storage systems where space is less critical than safety and lifetime

If you’re comparing LFP vs NMC battery packs in the U.S. market, LFP usually wins on cost, safety, and life; NMC wins on range and weight.

NCA, LMO and Other EV Chemistries

Beyond NMC and LFP, there are other lithium‑ion chemistries you’ll see:

- NCA (Nickel Cobalt Aluminum)

- Very high energy density and power

- Used by some premium EV makers for long‑range packs

- Needs robust battery pack thermal management and strict BMS control

- LMO (Lithium Manganese Oxide)

- Good power and safety, but lower energy density

- Often used in hybrids or blended with other chemistries

These blends let OEMs tune their traction battery pack for specific duty cycles (performance, heavy‑duty, or low‑cost).

Solid‑State and Semi‑Solid Battery Packs

Solid‑state battery packs replace the liquid electrolyte with a solid material. On paper, they promise:

- Much higher energy density

- Lower fire risk

- Faster charging and longer life

Reality today:

- Still in development, not yet mass‑market in EVs

- Early semi‑solid battery pack designs are closer to commercialization, mixing liquid and solid elements to improve safety and energy density without a complete redesign.

If you’re planning for future platforms, you’ll want a pack design that can evolve as these chemistries mature.

Comparing Electric Battery Pack Chemistries

Here’s how the main chemistries stack up on the key metrics:

| Chemistry | Energy Density | Cost | Safety | Cycle Life | Typical Use |

|---|---|---|---|---|---|

| NMC | High | Medium/High | Medium | High | Mainstream EVs |

| LFP | Medium | Low | High | Very High | Entry EVs, storage |

| NCA | Very High | High | Medium | High | Long‑range/performance EVs |

| LMO | Medium/Low | Medium | High | Medium | Hybrids, blends |

| Solid‑State (future) | Very High* | Unknown | Very High* | Very High* | Next‑gen EVs |

*Projected, not yet proven at EV scale.

The right choice depends on what you care about most:

- Max range / minimal weight: NMC or NCA

- Lowest cost and strong safety: LFP

- Future‑proof performance: track solid‑state and semi‑solid roadmaps

Whatever chemistry you choose, pack‑level design, EV battery cooling system, and BMS logic are just as critical as the cells themselves. If you want a deeper dive into safety trade‑offs between these chemistries at the pack level, I break that down in our overview of key safety features in EV battery packs.

Key Electric Battery Pack Specs to Understand

When you’re comparing an EV battery pack or a home storage system in the U.S., these are the specs that really matter.

Battery Capacity (kWh vs Usable kWh)

- kWh (kilowatt-hours) = total energy the pack can store.

- Usable capacity = what the BMS actually lets you use to protect the battery from damage.

- Many packs advertise, for example, 80 kWh total but ~72–75 kWh usable.

- For range or backup-time planning, always use usable kWh, not the headline number.

Voltage: 400V vs 800V Battery Architecture

- 400V packs

- Common in most mainstream EVs today.

- Cheaper components, works fine with typical DC fast chargers.

- 800V battery architecture

- Higher efficiency and much faster DC fast charging (shorter stops on road trips).

- Enables lighter wiring and better performance, popular in newer premium and truck platforms.

For U.S. buyers, 400V is still the norm, but 800V is where the market is heading as charging networks improve.

C-Rate, Discharge Rate & Peak Power

- C-rate = how fast a battery charges or discharges relative to its capacity.

- 1C for a 100 kWh pack = 100 kW charge/discharge.

- Higher C-rate = more power (better acceleration, stronger regen, faster charging), but more heat.

- Look for:

- Continuous discharge power (for highway performance/towing).

- Peak power (for short bursts, like hard acceleration or passing).

Our battery pack design balances high C-rate performance with tight thermal management so you get power without killing cycle life.

Energy Density (Wh/kg and Wh/L)

- Gravimetric energy density (Wh/kg)

- How much energy per unit of weight.

- Higher = lighter pack for the same range (better efficiency, handling, and payload).

- Volumetric energy density (Wh/L)

- How much energy per unit of space.

- Higher = more compact pack (more cabin space, better packaging).

For U.S. trucks, SUVs, and vans, energy density is critical to avoid massive, heavy packs that cut into payload and efficiency.

Cycle Life, Calendar Life & Degradation

- Cycle life = how many full charge–discharge cycles before capacity drops (typically to 70–80%).

- Calendar life = how long the pack lasts just sitting in time, even with light use.

- Degradation is driven by:

- High temperatures

- High SOC (staying near 100% all the time)

- Frequent DC fast charging

- Solid EV packs in the U.S. market today often deliver 8–15 years of usable life, depending on chemistry and use.

Charging Speed, Fast Charging & Connector Standards

- Charging speed depends on:

- Pack voltage (400V vs 800V)

- Max charge C-rate

- Thermal management (how well the EV battery cooling system handles heat)

- Connector standards in the U.S.:

- CCS: Still common on many existing EVs and public chargers.

- NACS (Tesla-style): Rapidly becoming the default U.S. standard; most new OEMs are switching to it.

- For road-trip-heavy drivers, look at:

- Peak DC fast charge power (kW)

- 10–80% charge time

- Which network and plug type your EV supports

If you want to dig deeper into how these specs affect real vehicles and suppliers, I recommend checking the latest data on the global EV battery pack market outlook through 2030, as well as how top global EV battery pack suppliers are configuring capacity, voltage, and charging performance for North American customers: top 10 global EV battery pack suppliers.

Electric Battery Pack Types by Application

When I design or source an electric battery pack, I always start with where and how it will be used. Cars, e-bikes, forklifts, and home storage all need very different pack designs.

EV Battery Packs for Cars and Trucks

Traction battery packs for passenger EVs and pickups need:

- High energy for long range (usually 40–200+ kWh)

- High power for fast acceleration and highway merging

- High-voltage battery pack (typically 400V or 800V architecture)

- Strong crash structure, pack enclosure, and liquid cooling

Most U.S. automakers balance cost and performance with LFP vs NMC battery chemistries, depending on whether the priority is range, towing, or price.

If you’re shortlisting suppliers, it’s worth looking at how leading EV battery pack manufacturers in China structure their traction packs and safety systems, as covered in this overview of top EV battery pack manufacturers in China.

Battery Packs for Electric Motorcycles and E-Bikes

These applications prioritize size, weight, and convenience:

- Lower voltage (often 36–96V), simpler BMS monitoring and control

- Removable, carryable packs for charging indoors

- Often air-cooled, with rugged housings for vibration and weather

- Strong focus on cycle life and real-world abuse tolerance

Here, energy density battery pack metrics (Wh/kg) and durability matter more than ultra-fast charging.

Home and Commercial Energy Storage Battery Packs

For U.S. homes, businesses, and EV energy storage systems:

- Goal is stable, long-duration energy, not acceleration

- Higher capacity per unit (10–500+ kWh) but lower C-rate

- Safety-first chemistries like LFP lithium-ion battery pack

- Modular electric vehicle battery module style stacks for easy expansion

- Usually 48V–1500V DC, with strong battery pack safety standards

These storage packs are optimized for daily cycling, solar integration, and long battery pack cycle life with minimal degradation.

Marine and Aviation Battery Pack Applications

Boats, ferries, drones, and eVTOL aircraft need:

- Extremely high energy density and robust battery pack thermal management

- Advanced BMS with tight EV battery cooling system control

- Very strict isolation, enclosure, and certification requirements

- Often custom, high-voltage designs with redundancy for safety

Weight and safety are king here. Many designs push toward solid-state battery pack or semi-solid chemistries in the future.

Industrial, AGV, and Robotics Battery Packs

Forklifts, warehouse AGVs, and robots demand:

- High uptime and fast opportunity charging

- Strong housings for impacts, dust, water, and 24/7 use

- Stable chemistries (often LFP) with long calendar life

- Flexible voltage options and custom battery pack manufacturer support

These packs are built to survive rough handling, uneven temperatures, and constant charge/discharge.

Traction Battery Pack vs Storage Battery Pack

The biggest design split is between traction packs (for moving vehicles) and stationary storage:

Traction battery pack (EV, e-bike, AGV):

- Optimized for power, acceleration, and regen braking

- Higher C-rates, stricter vibration and crash requirements

- Complex high-voltage wiring, contactors, and safety logic

- Aggressive fast charging EV battery support

Storage battery pack (home, commercial, grid):

- Optimized for energy, longevity, and low cost per kWh

- Lower power output, more predictable operating conditions

- Focus on thermal stability, long warranty, and low maintenance

- Easier scaling with modular racks and cabinets

If you’re in the U.S. and trying to spec the right pack for your project or product, it helps to follow a clear question set like the one used in this guide to the top questions to choose an EV battery pack.

Top Electric Battery Pack Manufacturers

Global EV Battery Pack Market Overview

The global EV battery pack market is now one of the most strategic industries in the world. Battery packs are the single most expensive component in an electric vehicle, and they decide range, performance, safety, and total cost of ownership. In the U.S., OEMs are rushing to lock in long-term supply as demand for EVs, plug-in hybrids, and energy storage systems keeps climbing, pushed by IRA incentives and state-level clean energy policies.

Today, the market is dominated by a handful of large Asian suppliers, while new Western and U.S.-based players are scaling up fast to localize production, reduce supply chain risk, and meet domestic content rules.

Chinese, Korean, and Western Battery Pack Suppliers

Most EV battery packs on the road today come from:

- Chinese manufacturers – CATL, BYD, EVE, CALB, and others lead in cost, scale, and LFP (lithium iron phosphate) technology. They dominate global volume and are strong in both traction battery packs and stationary energy storage.

- Korean manufacturers – LG Energy Solution, Samsung SDI, and SK On are core suppliers for many U.S., European, and Korean automakers. They’re strong in NMC and NCA lithium-ion battery pack chemistries with high energy density.

- Western manufacturers – Panasonic (Japan/U.S.), Northvolt (EU), and a growing number of U.S.-based pack integrators are serving American and European OEMs who want localized, high-voltage battery pack production with tighter control over IP and supply security.

For U.S. customers, the mix usually comes down to three things: chemistry (LFP vs NMC), cost per kWh, and ability to meet local sourcing rules and safety standards.

Where LEAPENERGY Fits in the Supply Chain

As LEAPENERGY, we position ourselves as a full-stack EV battery pack partner rather than just a cell supplier. We focus on:

- Pack engineering and integration – custom high-voltage battery pack design (400V and 800V architectures) for EVs, off-road, storage, and industrial applications.

- System-level safety and control – advanced BMS monitoring and control, robust pack enclosures, and integration with OEM vehicle control systems and battery disconnect units. For example, we track the latest battery disconnect unit (BDU) suppliers and technologies to keep safety and fault isolation at a high level.

- Localized solutions for U.S. customers – aligning with U.S. regulations, charging standards (CCS, NACS), and certification requirements so our packs are ready for North American deployment.

We can source cells from top-tier global partners or integrate around a customer’s preferred cell vendor, then deliver a complete, validated electric battery module and pack solution.

Production Capacity, Certifications, and Quality Standards

For serious OEM programs, battery pack manufacturing must hit three non-negotiables: capacity, repeatability, and compliance. We build around:

- Scalable production capacity – modular lines that can ramp from pilot to mass production while keeping quality consistent.

- Automotive-grade certifications – compliance with UL, ISO, and functional safety standards is core. We work to align with critical EV battery certifications like UL 2580 and ISO 26262 for pack-level functional safety, similar to what we detail in our guide to UL 2580 and ISO 26262 EV battery certifications.

- Process control and traceability – strict QC, full lot traceability, and data logging across pack assembly (cells, busbars, BMS, sealing, and end-of-line testing).

This is what U.S. OEMs and fleet operators look for: not just cheap kWh, but predictable quality and documented safety.

How OEMs Choose an Electric Battery Pack Manufacturer

When an automaker or equipment OEM picks a battery pack partner, they usually run through a hard checklist:

- Technical fit – Can the supplier hit the required voltage, energy density, C-rate, and cycle life with the right chemistry (LFP vs NMC vs others)?

- Safety and validation – Proven track record with thermal management, BMS logic, and compliance with EV battery pack safety standards.

- Cost and long-term roadmap – Competitive battery pack price per kWh today, plus a realistic roadmap toward lower cost and higher performance (CTP, 800V, solid-state readiness).

- Manufacturing footprint – Ability to deliver at scale, in-region, with strong after-sales and warranty support.

- Collaboration – Willingness to co-design, integrate into vehicle platforms, and support custom battery pack development instead of forcing a one-size-fits-all product.

Our approach at LEAPENERGY is built around these exact points: design support up front, transparent engineering, and long-term production partnership for U.S. and global customers.

Electric Battery Pack Safety and Standards

When we talk about an electric battery pack in the U.S. market, safety is non‑negotiable. High‑voltage energy, fast charging, and harsh real‑world conditions mean the pack has to be engineered to fail safe, not fail hard.

Main Risks: What Can Go Wrong

The big three risks in an EV battery pack or energy storage system are:

- Thermal runaway – a cell overheats, triggers neighboring cells, and the pack can catch fire.

- Internal or external short circuits – damaged cells, wiring faults, or crushed modules can create a direct path for current.

- Overcharge, over-discharge, or overcurrent – pushing the lithium-ion battery pack outside its safe window.

We design packs assuming “something will go wrong” and then build layers of protection around that.

Pack-Level Safety Design

Inside a modern high‑voltage battery pack, you’ll typically find:

- Fuses and pyrofuses – cut power instantly if current spikes.

- High‑voltage contactors & Battery Disconnect Units (BDUs) – act like smart relays to connect or isolate the pack; advanced BDUs are now a core EV safety layer.

- Isolation barriers – keep the HV side electrically separated from the vehicle chassis and low‑voltage system.

- Pre‑charge circuits – prevent inrush current that can damage components.

All of this works together with the battery management system (BMS) to shut the pack down before a fault becomes a fire.

Thermal Runaway Detection and Prevention

To keep an EV battery pack stable, we focus on stopping heat before it snowballs:

- Temperature sensors across cells and modules watch for hot spots.

- Gas/pressure sensors can detect early venting from a failing cell.

- Active thermal management (air or liquid cooling) keeps cells in a tight temperature band.

- Software limits on charging speed, discharge rate, and power output adjust in real time if the pack starts heating up.

If the BMS sees abnormal temperature rise or voltage behavior, it will cut power, open contactors, and log a fault.

Safety Standards and Regulations

If a pack doesn’t meet global safety standards, it’s simply not ready for the U.S. market. Key standards we design around include:

- UN38.3 – required for shipping lithium batteries; covers vibration, shock, crush, short circuit, and thermal tests.

- IEC standards – like IEC 62619 (industrial), IEC 62660 (EV cells), and IEC 62133 (portable).

- GB/T standards – increasingly important when working with Chinese cell and pack supply chains.

- Automotive and grid codes – FMVSS, SAE, UL, and NFPA guidelines for crash safety, fire behavior, and EV energy storage system installation.

These standards are the baseline, not the finish line.

Lessons from Real-World Incidents

High‑profile EV battery fires in the U.S. and abroad have pushed the industry to:

- Improve cell screening and quality control.

- Upgrade cooling system design to avoid hot spots.

- Add better thermal barriers between modules.

- Enhance software and OTA updates to adjust charging profiles and safety limits after deployment.

Every incident feeds back into tighter design rules, both for traction battery packs and stationary storage.

How We Test and Validate Pack Safety

Before any electric battery pack goes into a customer car or energy system, it goes through:

- Abuse testing – nail penetration, crush, overcharge, short‑circuit, and thermal shock on cells and modules.

- Mechanical testing – vibration, shock, drop, and full crash scenarios for the pack enclosure and mounting.

- Environmental testing – humidity, salt spray, corrosion, and extreme hot/cold cycling.

- Electrical testing – isolation resistance, dielectric withstand, HV insulation breakdown, and fail-safe behavior.

- Software validation – making sure BMS protections trigger fast and predictably.

Our goal is simple: if something fails, it should do so in a controlled, contained way that protects the driver, the home, and the first responders.

Electric Battery Pack Cost and Price Trends

Battery Pack Price per kWh

Over the last decade, EV battery pack price per kWh has dropped from well over $1,000/kWh to well under $150/kWh at the pack level, and it’s still trending down. For U.S. buyers, that’s the main reason EV sticker prices are finally getting closer to gas cars. Long term, most forecasts put average pack prices under $80/kWh once large-scale LFP and next‑gen chemistries are fully ramped.

What Actually Drives EV Battery Pack Cost

The real cost drivers are:

- Raw materials: Lithium, nickel, cobalt, manganese, graphite, copper, and aluminum

- Cell technology: Energy density and yield (how many cells pass quality checks)

- Pack design: Complexity of the enclosure, cooling, BMS, wiring, and structure

- Manufacturing scale: High-volume automated lines can cut pack cost dramatically

- Quality and safety standards: Automotive-grade validation and certifications add cost but protect you

As a pack manufacturer, I always look at total cost per kWh over the pack’s full life, not just the upfront bill of materials.

LFP vs NMC: Chemistry and Pricing

Chemistry choice changes both cost and behavior:

- LFP (lithium iron phosphate)

- Typically cheaper per kWh and easier to scale

- Lower energy density but excellent safety and long cycle life

- Great match for U.S. city commuters, ride-share fleets, and energy storage

- If you want a deeper dive, I’d point you to data-backed reasons why LFP batteries are often the best value choice in many EV and storage applications: Top 10 reasons LFP batteries are best.

- NMC (nickel manganese cobalt)

- Higher energy density (more miles per kWh of pack)

- Usually more expensive due to nickel/cobalt content

- Better when you need maximum range or limited packaging space

In the U.S. market, we lean heavily on LFP where cost, safety, and longevity matter most, and use NMC where range is the primary selling point.

EV Battery Pack Total Cost of Ownership vs Gas

When you look past the sticker price, a well-designed EV battery pack usually wins over a gas vehicle on total cost of ownership:

- Energy cost: Electricity per mile is typically cheaper than gas per mile in most U.S. states

- Maintenance: No oil changes, fewer moving parts, reduced brake wear

- Longevity: Modern packs are engineered to last 8–15 years of typical daily driving

- Resale and second life: Packs can be repurposed into stationary energy storage instead of being scrapped

For fleets and high‑mileage drivers, the battery pack is often the biggest driver of long-term savings.

How Pack Design and Scale Lower Cost

We push cost down through smart engineering and volume:

- High-voltage architectures (400V/800V) allow thinner cables and lighter components

- Integrated designs (cell-to-pack, structural packs) remove modules and extra hardware

- Standardized platforms mean we reuse the same base design across multiple vehicles

- Gigafactory-scale production spreads R&D and tooling costs over millions of kWh

As we scale advanced 800V EV batteries with high-volume manufacturing, like the solutions we highlight in our 800V technology overview at Why LEAPENERGY leads in 800V EV batteries, the cost per kWh keeps dropping while performance moves up. That’s exactly how we make long‑range, fast‑charging EVs affordable for everyday drivers in the U.S.

New Tech and Future Electric Battery Pack Trends

Cell-to-pack (CTP) and cell-to-body (CTB)

Cell-to-pack and cell-to-body designs remove traditional modules and pack cells directly into the battery pack or even into the vehicle structure.

What this means for you:

- More range: higher energy density, less dead weight and space

- Lower cost: fewer parts, simpler assembly

- Better performance: stiffer structure, improved handling and crash behavior

We’re designing next‑gen CTP architectures to give U.S. OEMs more kWh in the same footprint, and CTB concepts for platforms that want the battery to double as a structural element.

800V battery platforms and high-power charging

The shift from 400V to 800V battery architecture is all about cutting charge times and improving efficiency:

- Higher DC fast-charging power with lower current (less heat, thinner cables)

- Shorter highway charging stops when paired with high‑power chargers

- Better efficiency in power electronics and long‑distance driving

Our pack platforms are being developed to support both 400V and native 800V systems so automakers can scale from mainstream EVs to high‑performance or commercial vehicles without redesigning the entire battery.

Silicon-anode, semi-solid, and solid-state packs

Next-generation cell tech will change what an EV battery pack can do:

- Silicon‑anode lithium‑ion: higher energy density and better fast‑charging potential, ideal for U.S. drivers with long commutes and road trips

- Semi‑solid batteries: reduce flammable liquid electrolyte, improve safety, and allow tighter packing

- Solid‑state battery packs: promise big jumps in energy density and safety, with cooler operation and potentially faster charging

We’re running parallel validation programs with multiple cell partners so when these chemistries are commercially ready, our packs and BMS are ready too.

Sodium-ion battery packs as an LFP alternative

Sodium‑ion battery packs are coming fast as a lower‑cost alternative to LFP:

- No lithium or nickel: more stable supply and lower material risk

- Great for standard‑range EVs and energy storage where cost and safety matter more than maximum range

- Good low‑temperature performance, important for colder U.S. states

We see sodium‑ion as a strong fit for residential and commercial ESS, and we’re already shaping pack designs that can drop into our commercial and industrial energy storage systems when cell supply scales up.

Structural and integrated battery packs

A structural battery pack is not just bolted in – it becomes part of the vehicle body:

- Higher stiffness and crash performance

- Less weight because the pack replaces parts of the chassis

- More interior room or more battery in the same body size

Our roadmap includes structural pack platforms that integrate directly into skateboard chassis and body‑in‑white, especially for U.S. OEMs targeting light trucks, SUVs, and high‑volume platforms.

LEAPENERGY innovation roadmap and R&D focus

As a leading EV battery manufacturer, we’re investing R&D where it directly impacts U.S. customers and fleets:

- CTP/CTB and structural packs for lighter, safer, longer‑range vehicles

- 800V‑ready high‑voltage battery packs that support ultra‑fast charging

- Advanced chemistries (high‑silicon, LFP+, sodium‑ion, semi‑solid) tuned for long cycle life and stable supply

- Smarter BMS and thermal management for better safety, higher usable capacity, and longer

Sustainability and Electric Battery Pack Recycling

Carbon footprint of EV battery packs

The carbon footprint of an EV battery pack comes from mining, materials, cell production, and pack assembly. In the U.S., as the grid adds more solar and wind, the lifetime emissions per mile of an EV beat gas cars by a wide margin—especially when the battery is built in efficient, large-scale plants and designed for long cycle life. Our focus at LEAPENERGY is simple: more miles per kWh produced, less CO₂ per pack.

Second-life uses for EV battery packs

When an EV battery pack drops to around 70–80% of its original capacity, it can still be extremely useful in lower-stress roles, like:

- Home and commercial energy storage

- Solar and wind peak shaving

- Backup power for critical loads

We design our packs so they’re easy to reconfigure for second-life EV energy storage instead of going straight to recycling.

Recycling methods: hydrometallurgical vs pyrometallurgical

Today, most lithium-ion battery pack recycling uses two main routes:

- Pyrometallurgical (smelting): High-temperature process, simpler but more energy-intensive and can lose some materials.

- Hydrometallurgical (chemical leaching): Uses chemical solutions to recover lithium, nickel, cobalt, and other metals with higher efficiency and lower emissions when done right.

We prioritize partners that use advanced hydrometallurgical processes to recover a higher percentage of critical materials at lower environmental impact.

Battery passports, ESG rules, and regulations

The U.S. and global markets are moving toward full traceability:

- Battery passports: Digital records of material origin, chemistry, carbon footprint, and recycling history.

- ESG rules: Pressure from investors and regulators for clean supply chains, ethical sourcing, and documented recycling.

- Global standards: EU Battery Regulation, extended producer responsibility (EPR), and local U.S. state-level rules are pushing all of us to prove our sustainability claims with data, not marketing.

How LEAPENERGY handles recycling and closed-loop systems

At LEAPENERGY, we treat end-of-life as part of the original battery pack design, not an afterthought:

- We design for easy disassembly of modules, busbars, and enclosures.

- We work with certified recyclers to recover lithium, nickel, cobalt, copper, and aluminum into a closed-loop supply chain.

- We support customers with take-back programs and documentation that aligns with future battery passports and ESG reporting.

If you’re planning a project and want to build recycling and second-life into it from day one, you can reach out to us through our LEAPENERGY contact page so we can design the right closed-loop strategy around your application.

Choosing the Right Electric Battery Pack

Picking the right electric battery pack is all about matching the pack to how you actually use the vehicle or system. I always start with use case first, specs second.

Key Questions Before You Choose an EV Battery Pack

Ask these upfront:

- What is the main use?

Daily commuting, long road trips, city deliveries, off‑grid storage, backup power, etc. - How far or how long do you need it to run?

Miles for EVs, hours of runtime for storage or equipment. - How fast do you need to charge?

Home Level 2, DC fast charging, 800V charging, or slow overnight only. - What’s your climate?

Very hot (AZ, TX, FL), very cold (MN, ND, MI), or mixed. - Any weight or space limits?

Small vehicles, motorcycles, e‑bikes, drones, robots, AGVs, marine hull space. - Safety and certifications?

UL, UN38.3, IEC, automotive, or aviation/marine standards. - Budget and total cost of ownership?

Lowest upfront cost vs. longest life vs. highest performance.

Electric Battery Pack Checklist: Core Specs

When I spec a lithium‑ion battery pack, I always run through this list:

- Power (kW)

- Determines acceleration, towing, peak load.

- High power = stronger inverter, wiring, and EV battery cooling system.

- Energy (kWh)

- Directly linked to range or runtime.

- More kWh = longer range, more weight, higher cost.

- Voltage (V)

- 48V / 72V: e‑bikes, carts, light equipment

- 200–450V: most EVs and home packs

- 600–900V: 800V battery architecture, high‑power charging, trucks, premium EVs

- Weight & Size

- Check max payload, roof/rack load, under‑floor packaging, and center of gravity.

- Safety Features

- Strong battery pack enclosure

- Fast‑acting fuses, contactors, isolation

- Robust battery management system (BMS) monitoring and control

- Proven thermal management and certifications

Match the Battery Pack to Climate, Charging, and Use

In the U.S., conditions change a lot by region. I always adjust battery pack design for:

Climate

- Cold states (MN, WI, NY, CO):

- Prioritize packs with active thermal management and pre‑conditioning.

- LFP can lose power in deep cold; NMC/NCA often performs better.

- Hot states (AZ, NV, TX, FL):

- Demand strong battery pack thermal management (liquid cooling > air).

- Look for tighter degradation control and strong pack insulation.

Charging Setup

- Mostly home Level 2 → You don’t need huge peak charging power; focus on cycle life.

- Frequent DC fast charging → Go for packs validated for fast charging EV battery use and heat control.

- Access to 800V chargers → Consider 800V battery pack for shorter stop times.

Use Profile

- Short city trips → Smaller kWh, high cycle life, solid safety.

- Long‑distance highway → Higher kWh, high energy density battery pack, strong cooling.

- Fleet / delivery / rideshare → Durability, battery pack cycle life, easy diagnostics, and strong warranty come first.

- Stationary storage → Energy‑focused pack, high cycle life, fewer power spikes.

Common Battery Pack Sizing Mistakes

I see the same errors over and over:

- Oversizing “just in case”

- Costs more, weighs more, and you carry unused capacity every day.

- Undersizing to save money

- Leads to range anxiety, deeper cycles, faster battery pack degradation.

- Ignoring climate impact

- A pack sized for California can disappoint in North Dakota winters.

- Chasing peak numbers only

- Peak kW or “max range” doesn’t matter if usable capacity and real‑world conditions aren’t clear.

- Not checking usable vs. nominal kWh

- Some packs lock more capacity in reserve for life and safety.

Custom Battery Pack vs Off‑the‑Shelf

Here’s how I decide:

Off‑the‑shelf battery pack fits when:

- Voltage, capacity, and size already match your EV or system.

- You’re okay with standard LFP vs NMC battery choices.

- You don’t need special certifications or extreme performance.

You need a custom battery pack when:

- You’re building or retrofitting: robotics, AGVs, marine, aviation, specialty EVs.

- You have strict size/weight limits or need a structural battery pack.

- You need unique voltage, connectors, CAN protocol, or integration with your own BMS.

- You must meet specific U.S. or global battery pack safety standards.

How to Work With a Custom Battery Pack Manufacturer

Working with a custom battery pack manufacturer (like we do) goes smoother when you bring clear data:

- Define Requirements Clearly

- Voltage range, kWh, peak/continuous power

- Max weight and dimensions

- Target cycle life and warranty

- Operating temperature range (min/max)

- Share Your Use Case

- Drive/usage profile, daily mileage or hours

- Charging pattern and infrastructure

- Safety and certification targets (UN38.3, UL, IEC, etc.)

- Agree on Chemistry and Architecture

- NMC vs LFP vs others based on cost, safety, and life

- 400V vs 800V architecture

- Module‑based vs cell‑to‑pack / cell‑to‑body approaches

- Plan Validation and Support

- Prototype testing, abuse tests, environmental tests

- BMS integration, CAN communication, software updates

- Service model, battery pack warranty, and replacement path

If you size the EV battery pack around your real‑world usage, local climate, and charging reality, you get better range, better longevity, and a lot fewer surprises down the road.

Electric Battery Pack FAQs

Real‑world EV and battery pack questions

I hear the same questions from U.S. drivers and engineers over and over. Here are direct answers based on how modern EV battery packs actually work in the real world.

How do charging habits affect EV battery life?

Your charging routine has a big impact on battery pack degradation and cycle life.

Best practices for daily use:

- Live between ~20%–80% for daily driving when you can

- Use DC fast charging sparingly (great for road trips, not every day)

- Avoid leaving the pack at 0% or 100% for long periods

- Charge slower at home (Level 2) when time allows

- In very hot or very cold weather, let the thermal management system precondition before fast charging

Done right, normal U.S. commuting won’t “kill” your high‑voltage battery pack. Most loss comes from time, heat, and constantly pushing the pack to its extremes.

How long do electric battery packs really last?

For today’s lithium‑ion EV battery packs (NMC, LFP, NCA):

- Most drivers in the U.S. can expect 8–15 years of useful life

- Many packs still have 70–80% of original capacity after 150,000–250,000 miles, depending on chemistry and use

- LFP battery packs usually lose capacity slower but have lower energy density

- Hot climates (AZ, NV, TX, FL) and constant DC fast charging can shorten life if the EV’s cooling system isn’t strong

In practice, the car is often ready to be replaced or sold before the battery pack is fully worn out. Many used EV packs move into second‑life energy storage after vehicle use.

When should you replace or service an EV battery pack?

You don’t replace an EV pack like a 12V car battery. You replace or service it when:

- You’ve lost significant range (for most people, below ~65–70% of original capacity)

- The BMS shows cell imbalance, high internal resistance, or frequent fault codes

- There’s physical damage, water ingress, or crash damage to the pack enclosure

- Your range drops fast over a short time, not gradually

Important:

- Always get a diagnostic report (BMS data, cell health) before replacing a pack.

- Often, a module‑level repair or updated software can fix an issue without a full pack swap.

What about warranty, maintenance, and software updates?

Most major EV brands in the U.S. offer:

- 8 years / 100,000–150,000 miles battery warranty (varies by OEM and state)

- A guarantee the pack won’t drop below 60–70% of original capacity during the warranty period

Maintenance is mostly software and inspection:

- No regular “battery service” like oil changes

- Periodic checks of:

- High‑voltage connectors and seals

- Cooling system (coolant level, leaks, pumps)

- Pack enclosure and underbody shields

- Over‑the‑air (OTA) updates can:

- Improve charging curves

- Refine battery management system (BMS) algorithms

- Fix bugs that affect range prediction and pack protection