In the fast-evolving electric vehicle (EV) market, choosing the right battery pack supplier is critical. The EV battery supply chain is facing unprecedented volatility—from raw material shortages to shipping delays—that can disrupt your production timeline and inflate costs. Asking the right questions helps you identify suppliers who are not only reliable but also transparent and resilient under pressure.

On top of supply chain hurdles, regional compliance adds another layer of complexity. In the U.S., the Inflation Reduction Act (IRA) has set strict guidelines around sourcing and manufacturing to qualify for tax credits. Meanwhile, the European Union’s Battery Regulation imposes stringent requirements on sustainability, traceability, and recycling. Ensuring your supplier meets these evolving standards is vital to avoid costly penalties and maintain market access.

Given these challenges, it’s clear that thorough supplier vetting goes beyond price and delivery. It’s about verifying certifications, understanding production capabilities, and evaluating long-term support. That’s why we’ve put together the top 10 questions every EV manufacturer should ask before selecting a battery pack supplier—helping you navigate risks and secure a dependable partnership.

Top 10 Questions to Ask Your Potential EV Battery Pack Supplier

When choosing an EV battery pack supplier, asking the right questions ensures you get a reliable, high-quality product that fits your project’s needs. Here are the top 10 questions you should have ready:

1. What certifications and compliance standards does your battery pack meet

Safety and regulatory compliance are non-negotiable. Confirm the supplier meets safety standards, relevant OEM certifications, and has experience with regulations like the IRA and EU Battery Regulation. Watch out for vague answers or lack of documented certification. For example, LEAPENERGY holds multiple safety certifications that prove commitment to quality.

2. Can you provide details on your battery chemistry, cell sourcing, and energy density specs

Different chemistries suit different applications, so understand their energy density and sourcing transparency. A trustworthy supplier shows full traceability and often vertical integration, which stabilizes supply chain risks. LEAPENERGY’s infographic breakdown highlights these details clearly.

3. What is your battery pack’s projected lifespan, warranty terms, and degradation rate under real-world conditions

Premature battery failure is costly. Ask for cycle life data and explicit warranty terms covering actual usage scenarios. LEAPENERGY offers strong degradation guarantees based on tested real-world data, giving peace of mind over battery longevity.

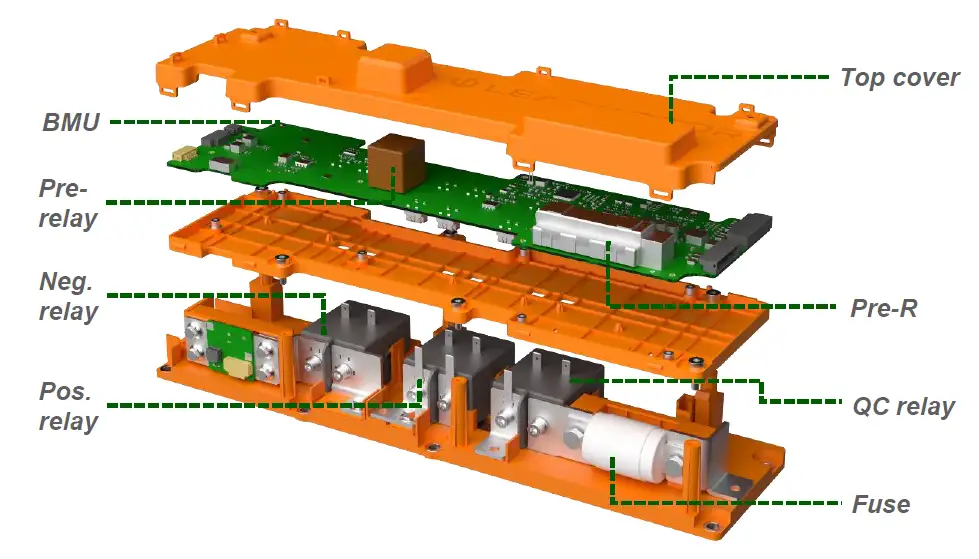

4. How does your Battery Management System ensure safety, thermal management, and state of charge accuracy

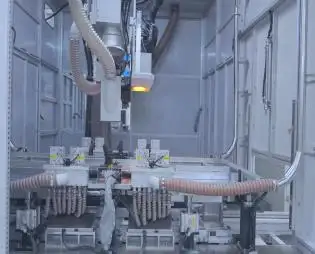

Effective BMS design prevents thermal runaway and optimizes performance. Make sure they don’t rely on generic off-the-shelf BMS but provide customized solutions tailored for your pack. LEAPENERGY’s BMS includes advanced fault detection and SOC accuracy measures.

5. What are your typical lead times for production, prototyping, and scaling to volume orders

Project timelines depend heavily on supplier reliability. Lead times should be realistic and flexible enough to handle issues. A strong supplier diversifies sourcing and communicates clearly about production scaling. LEAPENERGY’s supply chain strategies help avoid costly delays.

6. Can you share case studies or references from EV OEMs

Real-world reliability is key. Ask for case studies, pilot projects, or references—even if NDA restricted—to verify performance. LEAPENERGY can share anonymized success stories validating their battery pack performance in demanding environments.

7. What is your pricing structure including volume discounts, minimum order quantities, and hidden costs like shipping or tooling

Stay ahead of surprise costs by understanding all pricing components. Transparent tiered pricing with clear volume discounts helps you plan budgets effectively. LEAPENERGY provides straightforward pricing without hidden fees, illustrated in their pricing comparison tables.

8. How do you support customization for our EV specs such as voltage, form factor, or integration with our BMS

Your EV project is unique, so choose a supplier offering flexible design and in-house engineering support. Avoid suppliers that only offer rigid, off-the-shelf packs. LEAPENERGY’s rapid prototyping and custom solutions ensure perfect fit and integration.

LEAPENERGY BMS DETAIL

9. What is your quality control process, failure rate, and end-of-life recycling and sustainability practices

Meeting ESG goals and reducing waste should be part of your supplier’s DNA. Ask about defect rate benchmarks and recycling partnerships for second life or zero waste programs. LEAPENERGY leads with a zero waste initiative and robust quality assurance.

10 What ongoing support do you offer post-purchase including technical assistance, firmware updates, and RMA processes

Easy access to technical support and firmware upgrades minimizes downtime and maintains performance over the battery pack’s lifetime. Confirm availability of 24/7 support, defined SLAs, and OTA update capabilities. LEAPENERGY stands out with comprehensive post-sales service.

These questions cover everything from sourcing and safety to pricing and support—key pillars when vetting an EV battery supplier you can trust.

Red Flags to Watch For and Next Steps in Supplier Evaluation

When choosing an EV battery pack supplier, watch out for common red flags that could cost you time and money:

- Unproven startups with no track record — Lack of real-world testing or client references can spell trouble.

- Opaque sourcing and supply chain transparency — If they can’t clearly show where cells and materials come from, risks increase.

- Rigid “off the shelf” products — Suppliers unwilling to customize packs to your specific EV needs may limit performance.

- Unclear warranty terms or vague degradation data — These can hide potential risks of early battery failure.

- No clear quality control or recycling policies — Missing sustainability or defect management can affect your brand and compliance.

To avoid these pitfalls, follow a simple 3-step vetting process:

- Request for Information (RFI) — Gather detailed data on certifications, battery specs, and company references.

- Site Visits and Audits — Verify manufacturing processes, quality controls, and supplier compliance in person or virtually.

- Pilot Orders and Testing — Start small with prototypes in your application to validate performance and reliability before scaling up.

At LEAPENERGY, we offer a no-obligation audit to help you assess your current or potential EV battery suppliers. Reach out to get expert insights tailored to the market compliance and production demands, ensuring your line keeps running smoothly and safely.

Why Partner with a Trusted EV Battery Manufacturer Like LEAPENERGY

Choosing the right EV battery pack supplier is more than just picking a vendor—it’s about partnering with a trusted manufacturer who delivers quality, reliability, and scalability you can count on. LEAPENERGY stands out because of our commitment-made battery packs, ensuring you get products tailored to meet regional standards like the IRA and strict safety regulations.

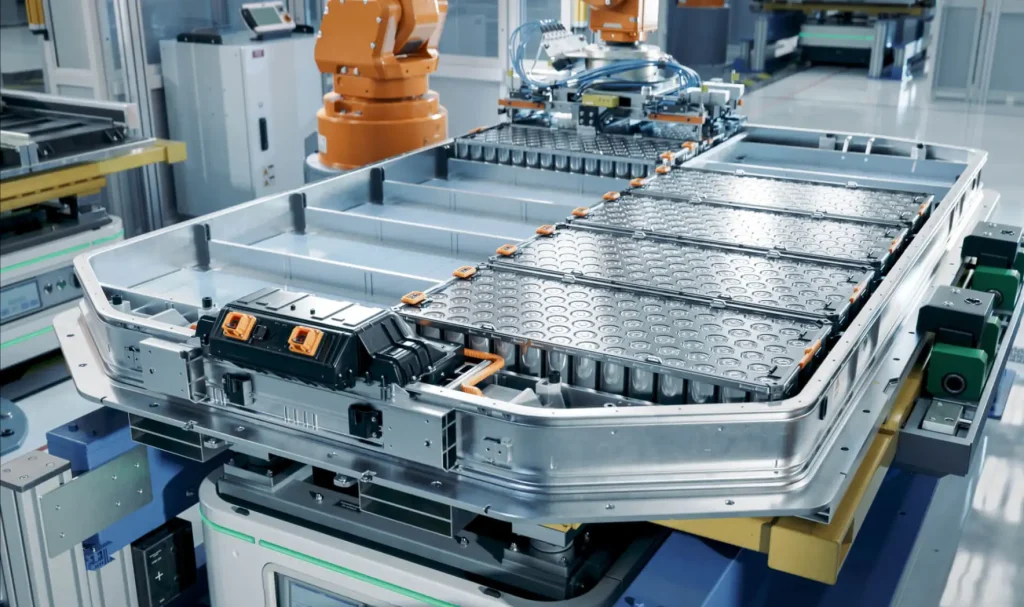

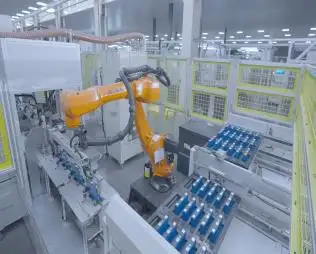

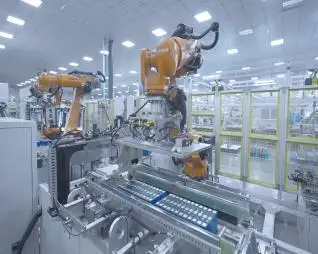

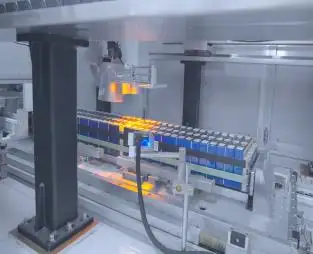

LEAPENERGY EV BATTERY PACK MANUFACTURE PROCESS

Our robust production capacity means we can handle everything from prototyping to high-volume orders without delays, helping you meet your project timelines even when supply chains get rocky. We’re also focused on transparency in our lithium ion battery sourcing and offer custom EV battery packs designed to fit your exact specs, giving you an edge in performance and integration.

If you want to explore how our certifications, battery management system integration, and quality assurance set us apart, check out our full range of LEAPENERGY services. Partner with us to reduce risk and future-proof your EV projects!