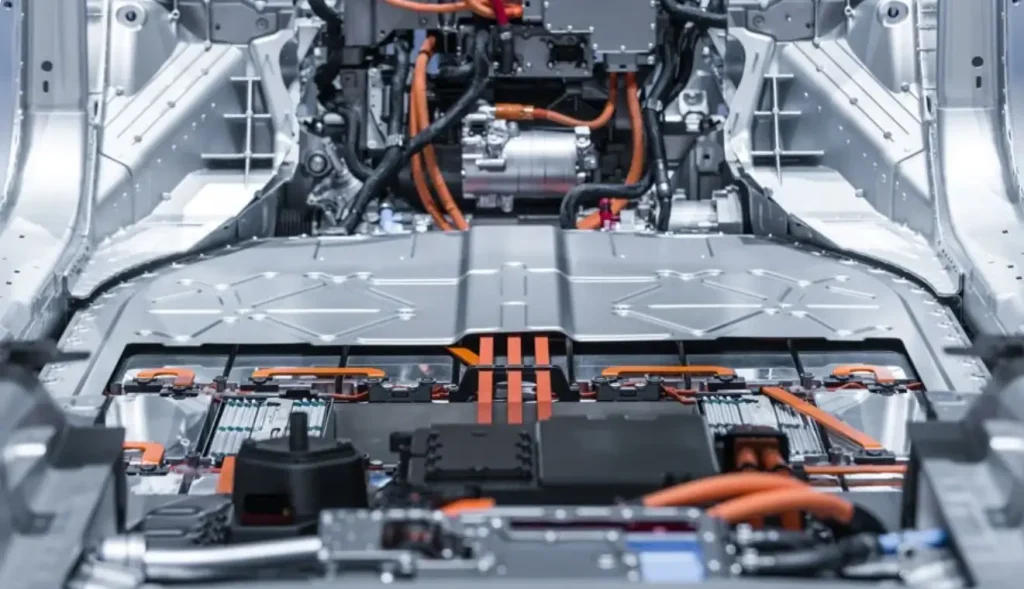

Electric vehicle (EV) battery packs are at the heart of modern EV design, combining multiple components to deliver power safely and efficiently. At their core, these packs consist of lithium-ion cells arranged in modules, which are then integrated into a complete battery pack using a modular battery design approach. This setup directly affects EV pack energy density and overall vehicle range.

Voltage plays a critical role in how these components work together. Higher voltage systems, like 800V platforms, enable faster DC charging speeds and improved electric vehicle range efficiency, thanks to reduced current flow and lower heat generation. Conversely, 400V architectures—long favored in many EVs—offer established reliability and easier compatibility with existing EV infrastructure.

Moreover, innovations like cell-to-pack (CTP) technology and structural design optimization contribute to better battery density improvement and pack integration. Voltage boost converters are often used to adjust voltage levels internally, enabling more flexibility in battery cell configurations.

In , understanding how core components and voltage interact helps clarify why different EV battery pack platforms serve varied needs—from affordability to ultra-fast charging. This foundational knowledge sets the stage for exploring the specific advantages and challenges of 400V and 800V battery architectures.

Advantages of 400V Battery Pack Platforms: Established Reliability and Cost Benefits

400V battery pack platforms have been the go-to choice for many electric vehicles, especially in the U.S. market, because they offer a balance of performance, reliability, and affordability. Here’s why they remain popular:

- Proven Technology: 400V systems have been widely adopted for years, meaning manufacturers and service centers are familiar with them. This results in easier maintenance and stronger support networks.

- Lower Cost Components: Parts like voltage boost converters and battery module design for 400V packs are generally less expensive than their 800V counterparts, helping to keep EV prices down.

- Simpler Battery Thermal Management: Managing heat in 400V packs is more straightforward, which reduces complexity in cooling systems and improves overall battery longevity.

- Better EV Infrastructure Compatibility: Most current fast DC charging stations in the U.S. support 400V systems, ensuring easier access to charging without needing specialized equipment.

- Modular Battery Assembly: The 400V design often allows for flexible battery pack configurations with proven cell-to-pack (CTP) technology, making pack integration and structural design optimization simpler.

| Feature | 400V Battery Pack Advantages |

|---|---|

| Reliability | High due to established manufacturing processes |

| Component Cost | Lower compared to 800V systems |

| Thermal Management | Simpler cooling, better battery lifespan |

| Charging Compatibility | Broad support across U.S. charging stations |

| Pack Design | Modular, easier assembly and repair |

For most everyday drivers focused on cost-effective, reliable electric vehicles, 400V platforms remain a solid choice. Their balance of performance and price fits well with current EV infrastructure across the U.S., making them practical for daily use and long-term ownership.

Advantages of 800V Battery Pack Platforms: Ultra-Fast Charging and Efficiency Gains

800V battery pack platforms bring a big leap in charging speed and overall performance. The higher voltage means EVs can handle much faster DC fast charging, cutting charging times significantly. For example, some 800V systems can go from zero to 80% charge in about 20 minutes or less, making them perfect for drivers who need quick turnarounds on long trips.

Beyond fast charging, 800V platforms improve energy efficiency. They reduce current flow in wires and components, which means less heat is generated. This helps with battery thermal management, lowering cooling system demands and allowing for more compact battery module designs. The use of advanced silicon carbide components in 800V setups also boosts efficiency by reducing energy loss during power conversion.

Additionally, higher voltage packs can support better pack integration and higher energy density, thanks to more flexible lithium-ion cell configurations. This means more range and better electric vehicle range efficiency without adding significant weight or size. Overall, 800V platforms are a future-proof choice for performance EVs and those seeking top-tier fast DC charging speeds combined with solid daily usability.

Challenges and Limitations: Heat, Cost, Compatibility, and Infrastructure Issues

Both 400V and 800V EV battery pack platforms come with their own set of challenges that you should consider, especially if you’re in the U.S. market where infrastructure and cost play big roles.

Heat Management:

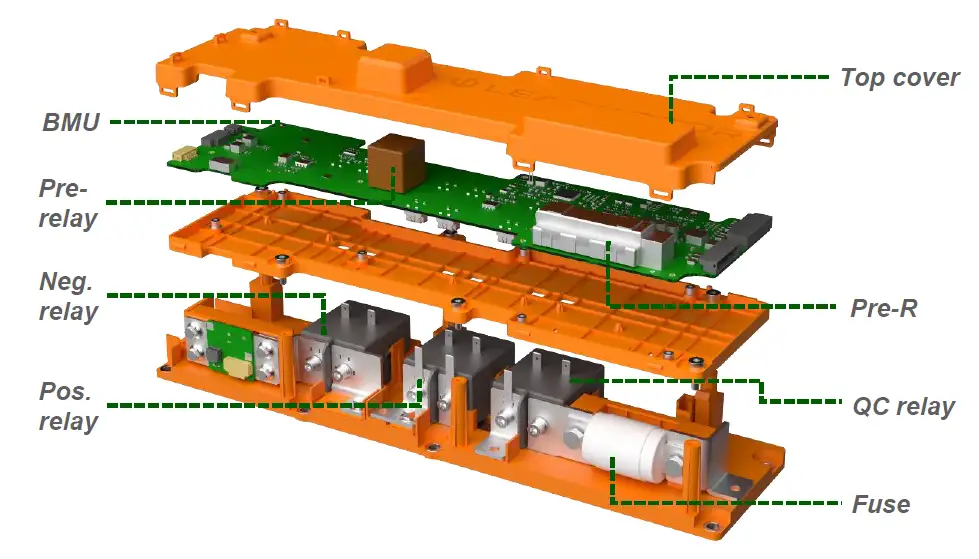

Higher voltage systems, like 800V platforms, generate more heat during fast DC charging and heavy use. This means EVs need more advanced battery thermal management to keep packs safe and efficient. That adds complexity and can affect reliability if not handled right.

VIEW LEAPENERGY BDU THERMAL MANAGEMENT

Cost Factors:

800V platforms often require pricier components—silicon carbide parts, specialized voltage boost converters, and more complex pack integration. For many buyers, this means a higher upfront price compared to the more established 400V packs, which benefit from economies of scale and simpler designs.

Compatibility Issues:

Not all EV chargers in the U.S. support 800V architectures yet. While 400V is widely compatible with existing EV infrastructure, 800V needs more specialized fast chargers. Until the network grows, this can limit convenience if you rely on public charging.

Infrastructure Limitations:

The U.S. is rapidly expanding fast DC charging stations, but a majority still cater primarily to 400V vehicles. So, if you’re considering an 800V EV, you should account for the current scarcity of compatible high-voltage chargers, especially outside major urban centers.

In short, while 800V platforms offer performance benefits, the heat management demands, higher costs, and charger compatibility issues can be sticking points. On the flip side, 400V packs offer a more proven, cost-effective option but might fall short in charging speed and efficiency as EV technology advances.

Choosing the Right Voltage for Your EV Journey: Trade-offs and Decision Guidance

Picking between a 400V and 800V battery pack for your electric vehicle comes down to your driving habits, budget, and charging needs. Here’s a quick breakdown to help you make a smart choice:

400V Battery Packs

- Best for everyday drivers: Plenty of reliable, cost-effective options

- Easier to maintain: Widely supported by current EV infrastructure

- Slower DC fast charging: Still decent, but not ultra-fast

- Lower upfront cost: Good for most U.S. buyers focused on affordability

800V Battery Packs

- Ideal for performance and long-range: Ultra-fast DC charging speeds

- Better energy efficiency: Helps extend electric vehicle range efficiency

- Requires advanced cooling: Battery thermal management is more complex

- Higher cost and fewer compatible chargers: Infrastructure is expanding but still limited in many areas

What to Consider

- Daily driving distance: If your trips are mostly local, a 400V pack likely covers your needs.

- Charging habits: If fast DC charging at public stations matters, the 800V platform offers clear benefits.

- Budget vs. performance: 400V packs deliver value; 800V packs bring speed and efficiency but at a premium.

- Compatibility: Check your area’s EV infrastructure to ensure chargers work well with your voltage choice.

In the end, balance the upfront cost, charging convenience, and your EV usage pattern. For most American drivers, a 400V battery pack hits the sweet spot between range, cost, and convenience. But if you want the latest tech with ultra-fast charging and efficiency gains—and are ready to invest—the 800V pack is the way to go.